Browse Econ Literature

- Working papers

- Software components

- Book chapters

- JEL classification

More features

- Subscribe to new research

RePEc Biblio

Author registration.

- Economics Virtual Seminar Calendar NEW!

Industry 4.0 in Management Studies: A Systematic Literature Review

- Author & abstract

- 19 References

- 16 Citations

- Most related

- Related works & more

Corrections

(Department of Economics, Engineering, Society and Business Organization, University of ‘Tuscia’ of Viterbo, 01100 Viterbo, Italy)

(Department of Management, Sapienza University of Rome, 00161 Rome, Italy)

- Corrado Gatti

Suggested Citation

Download full text from publisher, references listed on ideas.

Follow serials, authors, keywords & more

Public profiles for Economics researchers

Various research rankings in Economics

RePEc Genealogy

Who was a student of whom, using RePEc

Curated articles & papers on economics topics

Upload your paper to be listed on RePEc and IDEAS

New papers by email

Subscribe to new additions to RePEc

EconAcademics

Blog aggregator for economics research

Cases of plagiarism in Economics

About RePEc

Initiative for open bibliographies in Economics

News about RePEc

Questions about IDEAS and RePEc

RePEc volunteers

Participating archives

Publishers indexing in RePEc

Privacy statement

Found an error or omission?

Opportunities to help RePEc

Get papers listed

Have your research listed on RePEc

Open a RePEc archive

Have your institution's/publisher's output listed on RePEc

Get RePEc data

Use data assembled by RePEc

|

|

Academia.edu no longer supports Internet Explorer. To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser . Enter the email address you signed up with and we'll email you a reset link.

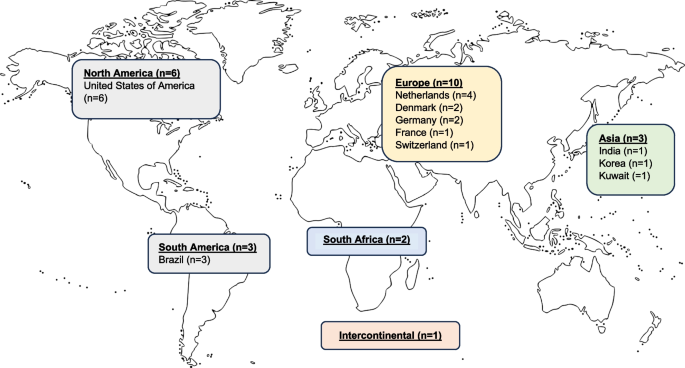

Industry 4.0 in Management Studies: A Systematic Literature Review Sustainability Recent developments in production processes and their automation have led to the definition of the Fourth Industrial Revolution, commonly known as “Industry 4.0”. Industry 4.0 is a very broad domain that includes: production processes, efficiency, data management, relationship with consumers, competitiveness, and much more. At the same time, obviously, Industry 4.0 has become a new theme for management scholars and business economics disciplines and a number of contributions covering various issues and aspects have been published. However, a systematic formulation of all these contributions is still lacking in management literature. Therefore, the aim of the paper is to analyze and classify the main contributions published on the topic of Industry 4.0 in management literature, seeking to give it a unique definition, discover the gaps still remaining in literature and outline future avenues of research in this domain. A systematic review of the literature of the major academic and re... Related PapersMichela PICCAROZZI Advanced manufacturing solutions, augmented reality, and cloud and big data are technologies pertaining to Industry 4.0. These technologies improve working conditions, create new business models, and increase both productivity and firm quality production. However, they can also improve life and society as a whole. This new perspective, oriented toward social and global well-being, is called Society 5.0. As has happened for all past industrial revolutions, Industry 4.0 will support the transition to a different society, i.e., Society 5.0. In this transition, open innovation and value co-creation can play an important role. The aim of the study was twofold: to examine how Industry 4.0 features and enabling technologies can support the transition to Society 5.0 and to investigate the roles of both open innovation and value co-creation within this transition. A conceptual framework was developed to jointly consider for the first time Industry 4.0, Society 5.0, open innovation, and value... Marco Savastano The digital transformation of manufacturing (a phenomenon also known as “Industry 4.0” or “Smart Manufacturing”) is finding a growing interest both at practitioner and academic levels, but is still in its infancy and needs deeper investigation. Even though current and potential advantages of digital manufacturing are remarkable, in terms of improved efficiency, sustainability, customization, and flexibility, only a limited number of companies has already developed ad hoc strategies necessary to achieve a superior performance. Through a systematic review, this study aims at assessing the current state of the art of the academic literature regarding the paradigm shift occurring in the manufacturing settings, in order to provide definitions as well as point out recurring patterns and gaps to be addressed by future research. For the literature search, the most representative keywords, strict criteria, and classification schemes based on authoritative reference studies were used. The fin... Applied System Innovation Dag Øivind Madsen This study provides an exploratory bibliometric analysis of the emerging literature on Industry 5.0, which is a new visionary concept on the future of industry. Industry 5.0 has in recent years begun to attract the interest of both practitioners and academics, but this new field can still be considered embryonic and not well documented. Therefore, this study aims to map the field and provide a preliminary picture of the emergence and status of the scientific literature on Industry 5.0. Bibliometric data covering the period from 2015 to 2021 were extracted from the Scopus database. Bibliometric analyses of overall publication volume and growth trajectory, influential documents, authors, sources and countries are performed. The exploratory analysis provides a preliminary overview of the birth and emergence of this new research area. The results are discussed in relation to theories on the emergence and evolution of new management concepts. The article closes with some speculations abo... Paola De Bernardi The concept of Industry 4.0 has been mainly addressed by the current literature from a technological perspective, overlooking the organisational and even ethical challenges related to this recent paradigm. In order to become ‘4.0 compliant’, an enterprise must adapt its organisation and business approaches, and these changes may lead to a significant impact on sustainability. Therefore, we performed a systematic literature review to investigate the most recent Industry 4.0 research streams by adopting a multi-perspective approach. This analysis led to collect insights on the key traits of an Enterprise 4.0: integration, decomposed hierarchy, flexibility, and autonomy. Each of these keywords involves work environments, business and organisational models, and educational approaches, which constitute the key traits of the novel framework proposed in this study. Industry 4.0 (I4.0) technologies have been highlighted in recent literature as enablers of servitisation. Simultaneously, businesses are advised to implement a circular economy (CE) to bring new opportunities. However, it is pertinent to mention that little attention has been given to assess the role of I4.0 in adopting the CE and servitisation in a fully integrated manner. This research fills this gap by developing a conceptual framework through a systematic literature review of 139 studies investigating the relationship between the I4.0, CE, and servitisation. This study identifies the impact of these variables on a firm’s operational and financial performance (revenue stream, growth, and profitability). Our research findings advocate that adopting I4.0 technologies to the business and manufacturing model enables sustainability, energy and resource efficiency while enhancing performance and offering innovative products through smart services. Thus, firms must systematically adopt ... In 2020, the whole world had to face a pandemic with inevitable profound changes in all aspects of life, from the social to the economic sphere. The profound economic crisis that followed the rise of the pandemic has pushed firms and researchers to question the necessary changes and new challenges for the survival of businesses. In this scenario, the aim of the paper is to analyze and classify the main contributions published on the topic of COVID-19 in managerial literature, seeking to discover the perspective and the gaps and outline future avenues of research. A systematic review of the literature has been performed. The results highlight the orientation of studies in this field and the various links between different aspects that emerged. Limitations and implications complete the research. Applied Sciences Carlo Andrea Bassani The enabling role of Digital Technologies towards the Circular Economy transition has been recognized. Nonetheless, to support the transition, the operationalization of the discourse is still needed. The present study performs a systematic literature review, deepening the knowledge on the role of Digital Technologies in operationalizing the Circular Economy transition. The analysis is shaped according to the ReSOLVE framework, as it has been recognized as able to operationally guide industrial firms towards the Circular Economy transition. Despite the broad focus on the topic by the extant literature, the results of the analysis show limited Circular Economy aspects addressed and specific technologies considered, making it difficult to have a complete overview on the implementation of Digital Technologies in the Circular Economy transition, operatively addressing it. Shortcomings are identified regarding the lack of an integrated and holistic analysis of the relationships, the need ... Administrative Sciences (ISSN 2076-3387) (ESCI & Scopus indexing) The Industry 4.0 (I4.0) concept is concerned with the fourth industrial revolution in manufacturing, in which technological trends such as digitalization, automation and artificial intelligence are transforming production processes. Since the concept's introduction at the Hannover Fair in Germany in 2011, I4.0 has enjoyed a meteoric rise in popularity and is currently high on the agenda of governments, politicians and business elites. In light of these observations, some commentators have asked the question of whether I4.0 is a concept that is hyped up and possibly just the latest in a long line of fashionable management concepts introduced over the course of the last few decades. Therefore, the aim of this paper is to provide a critical outside-in look at the emergence and rise of I4.0. Theoretically, these processes are viewed through the lens of management fashion, a theoretical perspective well suited to examinations of evolutionary trajectories of management concepts and ideas. The findings indicate that the I4.0 concept has quickly become highly popular and is dominating much of the popular management discourse. The concept has migrated out of the specialized manufacturing discourse to become a more general concept with mainstream appeal and applicability, evidenced by a multitude of neologisms such as Work 4.0 and Innovation 4.0. The numbers 4.0 have spread in a meme-like fashion, evidenced by the fact that the combination of a noun and the numbers 4.0 are used to signal and usher in discussions about the future of business and society. While there is much evidence that clearly shows that the concept has had a wide-ranging impact at the discursive level, the currently available research is less clear about what impact the concept has had so far on industries and organizations worldwide. Veljko Mijušković Industry 4.0 has been a major force framing the societal, economic and technological environment after 2010. Exposed to ongoing digital transformation, companies are able to exploit opportunities offered by Industry 4.0, and are forced to manage immanent risks and barriers. However, studies on opportunities and challenges relevant for the implementation of Industry 4.0 for companies are scarce. In response to this literature gap, the aim of this exploratory research is to provide a deeper analysis of the level of digital transformation of companies in Serbia based on a digital maturity model, and examine their managers’ opinions on the most important driving forces and implementation barriers. The paper uses exploratory research design based on a survey responded to by 122 high-level managers within the Serbian manufacturing sector. Findings show that, contrary to expectations, digitally transforming enterprises do not see human resources as a driving force, but rather as an obstacl... maria grazia saporito The present review retraces the steps of the industrial and agriculture revolution that have taken place up to the present day, giving ideas and considerations for the future. This paper analyses the specific challenges facing agriculture along the farming supply chain to permit the operative implementation of Industry 4.0 guidelines. The subsequent scientific value is an investigation of how Industry 4.0 approaches can be improved and be pertinent to the agricultural sector. However, industry is progressing at a much faster rate than agriculture. In fact, already today experts talk about Industry 5.0. On the other hand, the 4.0 revolution in agriculture is still limited to a few innovative firms. For this reason, this work deals with how technological development affects different sectors (industry and agriculture) in different ways. In this innovative background, despite the advantages of industry or agriculture 4.0 for large enterprises, small- and medium-sized enterprises (SMEs)... Loading Preview Sorry, preview is currently unavailable. You can download the paper by clicking the button above. RELATED PAPERSVojko Potocan Information Blanka Klimova Kwangho Jung Aldona Kluczek Shahryar Sorooshian Marian MOCAN VINCENZO VARRIALE Valeria Mininno Horst Treiblmaier DORIS MARIELA SILVA DELVASTO Yevgeniy Lukhmanov Marta Travaglioni Irena Pawłyszyn Sensors (Basel, Switzerland) Katalin Puskas Khetani Martin Pech Oshane Thorpe Pierpaolo Pontrandolfo Parkash Tambare Patricia Guarnieri Maximilian Espuny Paulo Peças Cristiano Jesus Loredana Paunescu Claudio Sassanelli Premaratne Samaranayake Luis Jesús Belmonte-Ureña Roman Kmieciak Nemer Rumman Anabela Alves Michał Organa layalee qtaishat Vasja Roblek , Maja Meško Luis Pérez-Domínguez Okechukwu Okorie RELATED TOPICS

Login to your accountChange password, your password must have 8 characters or more and contain 3 of the following:.

Password Changed SuccessfullyYour password has been changed Create a new accountCan't sign in? Forgot your password? Enter your email address below and we will send you the reset instructions If the address matches an existing account you will receive an email with instructions to reset your password Request UsernameCan't sign in? Forgot your username? Enter your email address below and we will send you your username If the address matches an existing account you will receive an email with instructions to retrieve your username

Cookies NotificationOur site uses javascript to enchance its usability. you can disable your ad blocker or whitelist our website www.worldscientific.com to view the full content., select your blocker:, adblock plus instructions.

Adblock Instructions

uBlock Origin Instructions

uBlock Instructions

Adguard Instructions

Brave Instructions

Adremover Instructions

Adblock Genesis Instructions

Super Adblocker Instructions

Ultrablock Instructions

Ad Aware Instructions

Ghostery Instructions

Firefox Tracking Protection Instructions

Duck Duck Go Instructions

Privacy Badger Instructions

Disconnect Instructions

Opera Instructions

System Upgrade on Tue, May 28th, 2024 at 2am (EDT)Industry 4.0 maturity and readiness models: a systematic literature review and future framework.

Department of Management Studies, Indian Institute of Science, Bangalore, India E-mail Address: [email protected] Search for more papers by this author Over the last five years, Industry 4.0 (I4.0) has gained a lot of attention from industry leaders, policymakers, and government officials worldwide. In an era where new concepts and techniques are introduced continuously, there is a lack of systematic literature review (SLR) on identifying main dimensions, levels, methods to assess the maturity and readiness level toward I4.0. To address this gap, we have chosen our primary objective to provide a critical review of existing literature on dimensions, methods, levels, and current trends to evaluate the I4.0 maturity and readiness models. A Preferred Reporting Items for Systematic Reviews and Meta-Analysis (PRISMA) methodology was adopted to make sure that there is no replication and to maintain complete transparency in the review process. A total of 53 papers were deemed relevant for thematic analysis. From the literature, we have found and proposed 10 main dimensions — Strategy and Organization, Manufacturing and Operations, Supply Chain, Business Model, IT, People, Customers, Product, Services, and Culture, to assess the I4.0 maturity and readiness levels of an organization. Further, a conceptual framework was proposed for the same. This study contributes theoretically to the development of I4.0 maturity and readiness models. So far, this is the first review paper on dimensions of I4.0 maturity and readiness models and is expected to give future researchers and practitioners a holistic guideline to design and develop I4.0 maturity and readiness models.

Recommended Received 10 March 2020 Revised 11 November 2020 Accepted 11 November 2020 Published: 9 January 2021 Lean supply chain management and Industry 4.0: a systematic literature reviewInternational Journal of Lean Six Sigma ISSN : 2040-4166 Article publication date: 22 August 2022 Issue publication date: 28 February 2023 Even though the integration of Lean Supply Chain Management (LSCM) and Industry 4.0 (I4.0) technologies is relatively recent, it has been receiving a lot of attention. Partly because it is a recent field of practise and research and partly because the number of works developed in this field has grown rapidly, it is important to frequently update the perspectives on this field of investigation. Thus, this study aims to review the integration between LSCM and I4.0 analysing relationship at operative, tactical and strategic levels. Design/methodology/approachSystematic literature review was conducted to identify and explain the integration of LSCM and I4.0 from scientific sources that were published before March 2021. The analysis of the literature revealed the level of integration of LSCM and I4.0 is present at different managerial levels. Moreover, when the integration is detailed at different managerial levels, it appears that LSCM paves the way for the adoption of I4.0 at a strategic level, while I4.0 technologies promise to enhance LSCM practices at the operational level. Research limitations/implicationsThe main contribution of this study is the framework which shows that LSCM paves the way for the adoption of I4.0 at a strategic level, while I4.0 technologies promise to enhance LSCM practices at the operational level. Originality/valueThis study develops a new perspective of the articles published under the thematic of LSCM and I4.0. Additionally, it proposes a framework of analysis that can be used by future researchers. Finally, it shows the most recent implementations of LSCM and I4.0, exposing the current trends, improvements and also the main gaps.

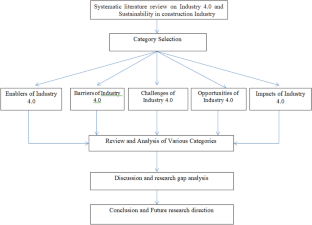

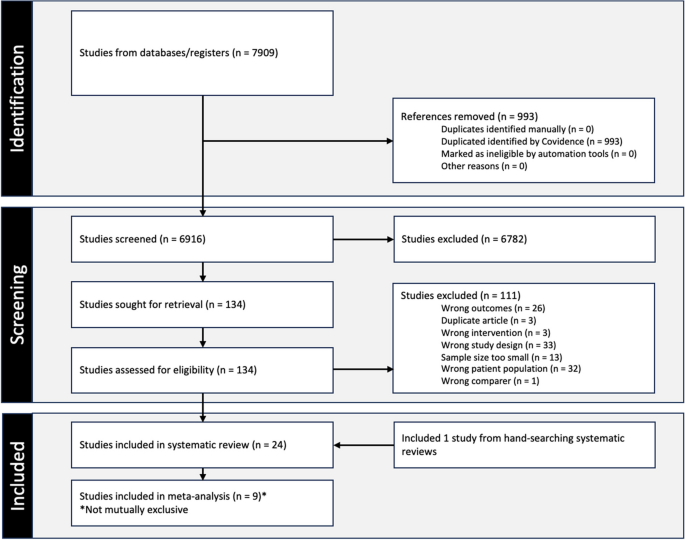

Rossini, M. , Powell, D.J. and Kundu, K. (2023), "Lean supply chain management and Industry 4.0: a systematic literature review", International Journal of Lean Six Sigma , Vol. 14 No. 2, pp. 253-276. https://doi.org/10.1108/IJLSS-05-2021-0092 Emerald Publishing Limited Copyright © 2022, Matteo Rossini, Daryl John Powell and Kaustav Kundu Published by Emerald Publishing Limited. This article is published under the Creative Commons Attribution (CC BY 4.0) licence. Anyone may reproduce, distribute, translate and create derivative works of this article (for both commercial & non-commercial purposes), subject to full attribution to the original publication and authors. The full terms of this licence may be seen at http://creativecommons.org/licences/by/4.0/legalcode 1. IntroductionSince the past decades, the Lean Supply Chain Management (LSCM) practices and principles have been successfully adopted across different sectors ( Chakrabarty and Wang, 2020 ). Such increasing interest is because LSCM implementation can bring several benefits in the form of cost reduction, throughput time shortening, quality and other aspects (Moyano-Fuentes et al. , 2020; Vanichchinchai, 2019). The advent of Industry 4.0 (I4.0) has re-opened the debate of the introduction of novel technologies in already established managerial system led by human-centred philosophy such as lean management ( Ghadge et al. , 2020 ). The modern information and communication technologies (ICT) of I4.0 make it possible to establish connection among the products, machines and processes. In this sense, many authors have spotlighted the potential benefits of integrating technologies such as Big Data analytics, Internet of Things and Cloud Computing in lean systems, generating great expectations and enthusiasm ( Buer et al. , 2020 ; Tortorella et al. , 2019a , 2019b ). Literature presents papers discussing interplay between LSCM and I4.0, but the topic is still in the novelty phase ( Núñez-Merino et al. , 2020 ). Moreover, the literature is presenting different perspective of analysis, which does not support the structure of such relationship, thereby creating chaos on the value of the interplay. Is there any interrelationship between Lean Supply Chain Management and Industry 4.0? To answer the research question, this study provides a systematic literature review (SLR). The article is structured as follows: Section 2 introduces and defines the domain of LSCM and I4.0, while Section 3 describes the applied methodology for the SLR. Section 4 outlines the findings of the study and presents the conceptual framework of the interplay between LSCM and I4.0. Section 5 concludes the article, indicating its limitations and future research opportunities. 2. Theoretical background2.1 lean supply chain management. Given the current situation where there is high turbulence in the customer demand and the competitive landscape is rapidly changing, firms grapple with the challenge of satisfying the desired needs of the customers (Vanpoucke et al. , 2014). According to Krajewski et al. (2015), the most successful companies are those that take into consideration the external customers and suppliers into their internal improvement processes. Thus, integration with suppliers and customers acts as an external aid to improve competitiveness and efficiency (Flynn et al. , 2010). One approach that can help supply chains to reduce waste and achieve sustainability is Lean Production (LP), based on the Toyota Production System ( Rossini et al. , 2019 ). As such, in an environment where the companies are competing for shorter lead times and better quality with cost reduction, LP practices can be implemented in the spirit of a supply chain integrative approach (Guilherme Luz Tortorella et al. , 2017 ). LSCM is the management of different organizations integrating both upstream and downstream flows of different entities that can increase value and reduce cost and waste by responding promptly to satisfy the demand of each customer ( Anand and Kodali, 2008 ; Saxby et al. , 2020). Thus, the aim of LSCM is to ensure that value is created and transferred efficiently to the downstream. The concept of LSCM is not only confined in automotive, construction or manufacturing companies but also extended to service firms such as hospitality, health care and retail ( Borges et al. , 2019 ). However, several studies on the topic have focused only on individual aspects of LSCM. In particular, many studies have concentrated only on analysing “upstream” lean practices, while scarcely any attention has been given on their application in the “downstream” (Reichhart and Holweg, 2007; Reitsma et al. , 2020 ). The gradual adoption of LP practices “downstream” in the flow could be justified by the production levelling (heijunka) concept, as there is a requirement of production to cope up with fluctuations with high market demand variability (Mason-Jones et al. , 2000). Nevertheless, it is found out that it is not possible to achieve complete sustainable results by applying LP principles only at upstream actors in the supply chain. Hines et al. (2004) indicated that the evolution of LP principles and practices over the years from the shop floor to every actor across the supply chain. They can be applied, from developing products and services, through placing orders with suppliers, to transporting the products to the customers ( Bittencourt et al. , 2021 ). Its aim is to continuously improve all the activities which will be beneficial for the customers. In this sense, LSCM highlights the importance of using LP practices effectively to create an efficient production and logistics system that meets the customers’ expectations ( Chu et al. , 2021 ). As stated by Agarwal et al. (2006) , LSCM requires a different business model, which should consider a strategic relationship with different supply chain actors and eliminate waste through cooperative and systematic approach. In this sense, the advent of new technologies opens many new options for LSCM, facilitating coordination and collaboration among supply chain partners and fostering integration to more competitive levels (Tortorella G., Miorando R., 2019). 2.2 Industry 4.0The term I4.0 was first coined out in 2011 by the German Industry–Science Research Alliance ( Buhr, 2017 ). Nowadays, I4.0 or simply the digital transformation creates many challenges for manufacturing companies from different points of view. The I4.0 can be seen as an expansion of ICT horizontally (Lee et al. , 2018). In fact, ICT is now used more extensively across all spheres, including business, government and everyday life. The digitalization of I4.0 helps to connect different entities across the whole supply chain through real time information ( Chiarini et al. , 2020 ). Because of this interconnection, different entities will be able to cope with the fluctuations in the environmental factors thanks to artificial intelligence ( Hecklau et al. , 2016 ). Mario et al. (2017) described I4.0 as “[…] a collective term for technologies and concepts of value chain organization”. Digitization is affecting all sectors, either replacing traditional products with digital counterparts or enhancing those products with new digital features (Prem, 2015). However, the digital transformation that results from a shift towards I4.0 goes beyond the improvement at the product and process levels. Though it has created revolution in production and business models, it left the companies with challenges ( Bleicher and Stanley, 2018 ). In particular, the ultimate goal of digitalization of manufacturing is to establish connection among all the actors in manufacturing value chains. In other words, digitalization enhances not only the physical products but also the business and the overall strategy of the organizational structure (Matt et al. , 2015). According to Meier (2016) , for the full digital transformation, the companies should first analyse and identify what customers want; then, they should perform the changes within the organization according to the customer needs. But the challenge for business remains on the speed and depth that the companies can adopt digital transformation ( Rossini et al. , 2021 ). It has been proved a strict link between the implementation of I4.0 technologies and lean systems (G.L. Tortorella et al. , 2019b ), but the research is focused on the single plant implementation and still misses a broader perspective of relationship outside the walls of the single plant, looking at the supply chain. Given that LSCM and I4.0 represent two relevant opportunities for business but their relationship is still unstructured, this paper aims to explore and discuss the potential synergy for firms adopting both approaches. 3. MethodologyTo explore the landscape of combining LSCM with I4.0, we adopted SLR. According to Fink (2005), a SLR is: […] a systematic, explicit, comprehensive and reproducible method for identifying, evaluating, and synthesizing the existing body of completed and recorded work produced by researchers, scholars, and practitioners. In this section, the methodology adopted to conduct the literature review is described. According to the authors, it can be said to be systematic to a fair degree, considering the strict procedure that has been used. Following the guidance of Xiao and Watson (2017), for a review to be successful, it should involve three phases: Planning, Conducting and Reporting. Figure 1 shows the reviews in eight different steps. In the following paragraphs, all the steps are detailly discussed and an explanation of how they have been put in practice is provided. Step 1: Formulating the problem The starting point for conducting a SLR is the formulation of the problem. The driving forces of the SLR process are the research questions ( Kitchenham and Charters, 2007 ), which are the aim of the formulation of the problem. A too broad research question could invalidate the SLR because of a huge amount of identified data to work with ( Cronin et al. , 2008 ). For this reason, the adequate research question could be identified with an iterative process. The foundation of the SLR is the relationship between the environment of lean supply chain and the one of I4.0. Therefore, the starting aim was to study how the two paradigms interact with each other. Gradually, conducting the initial research, a more structured and refined question has been necessary. Indeed, different relationships between lean supply chain and I4.0 could be identified in relation with different business sectors. Moreover, these relationships may have already been thoroughly studied in some sectors, while in other sectors, this research has just begun. This iterative process has been instrumental in identifying the boundaries of the research question of the SLR. Step 2: Developing and validating the review protocol The review protocol is “a preset plan that specifies the methods utilized in conducting the review” (Xiao and Watson, 2017), and it is absolutely crucial for rigorous systematic reviews. It should significantly reduce the bias during the analysis of the selected data (Kitchenham and Charters 2007). Step 3: Searching the literature The systematic search follows five steps. First, the channels for the literature search must be defined by researchers. As there are infinitely many channels available, researchers should choose a subgroup of channels. Second, the research question must be translated in keywords that could be used for the research. Third, researchers should identify the sampling strategy. According to the review requirement, the research can be either exhaustive or selective (Suri and Clarke, 2009; Bayliss and Beyer, 2015 ). Fourth, researchers should refine results with additional restrictions because there could be further practical criteria to exclude some papers from the SRL. Finally, it is important to identify a stopping rule that helps researcher to understand when the studies could be considered finished. Regarding the channels for literature review, among the countless available sources, Scopus has been chosen as the only database for this SLR. This choice is because this electronic storage delivers “a comprehensive overview of the world’s research output in the fields of science, technology, medicine, social sciences, and arts and humanities”. The following step is the identification of the keyword used for the search. For what concerns this study, as the aim is to study the relationship between LSCM and I4.0, the first keywords are “Lean”, “Supply Chain” and “Industry 4.0”. Given the need to have a comprehensive research environment, the search must be extended using synonymous, alternative spellings, abbreviations and related terms. Specifically, one synonymous of “Lean” is “JIT”, while the synonymous of “Industry 4.0” are “Digital” and “Smart”. Moreover, there is also an abbreviation for “Industry 4.0” that is “I4.0” and the alternative German spelling of “Industry 4.0” that is “Industrie 4.0”. To create the search strings, “AND” is used to join the main terms, while “OR” is used to include synonymous and abbreviations. Therefore, the final search string was {[(“JIT” OR “Lean”) AND (“Supply Chain”)] AND (“Industry 4.0” OR “I 4.0” OR “Digital” OR “Smart” OR “Industrie 4.0”)}. Table 1 synthesizes the final set of keywords, divided into the two themes addressed by this literature review. For what concerns the sampling strategy, the search can be either exhaustive or selected (Suri and Clarke, 2009; Bayliss and Beyer, 2015 ). This SLR is more selected and representative. For this reason, “grey literature”, such as conferences, was not included in the search papers. This decision stems from the fact that grey literature is considered of lower quality than peer-reviewed papers (Xiao and Watson, 2017). Moreover, “grey literature” could be affected by more biases than peer-reviewed papers. To further refine the results, additional restrictions have been applied including date range of publication and publication language. For what concerns the time horizon, documents published before 2011 were excluded from the research, as the term “Industry 4.0” came up for the first time during the Hannover Fair of that year. On the other side, the ending date of the research horizon corresponds to the end of 2020. As regards the publication language, the research has been confined to English language. Finally, according to Levy and Ellis (2006), a rule of thumb is to stop the search in case of obtaining the same references with no new results. In this case, the stopping rule has been applied to the research keywords. In particular, it has been tested that adding the new keywords “I4.0” and “Industrie 4.0” to identify I4.0 leads to the same results. For this reason, no other keywords besides those presented in Table 1 were included. Step 4: Screen for inclusion Once the search of articles has come to the end, a list of paper has been generated in the channel selected for literature search. From this list, researchers have to screen each article to identify the possibility of including it for data extraction and analysis. Starting from the articles list generated in previous steps, the authors should screen this list by reading the abstract of each article according to inclusion and exclusion criteria. This procedure should be done by each researcher to select the studies based on the inclusion and exclusion criteria ( Gomersall et al. , 2015 ). These criteria, that are based on the research question, should match with the practical situations and appropriate enough to classify the research. Moreover, they can be trustworthy and should result in a manageable source of literature (Xiao and Watson, 2017). Only when the screen of articles is completed by each researcher, they should compare the two respective outputs of this procedure. In the case of conflicting opinions, the paper should be included. Not peer-reviewed ( NR ): Articles found with the keywords previously described and that are not-peer-review should be discarded. Specifically, conferences articles are considered “grey literature”. For this reason, according to the sampling strategy adopted, these papers should be rejected, while only article and review types should be considered by researchers; Completely unrelated ( CU ): Papers which are not related to the relationship between lean supply chain and I4.0 should not be included in the literature review. Indeed, because of some keywords used, such as “Smart” and “Digital”, articles that have in their abstract these terms have appeared in the search list. However, these articles sometimes are not related to the relationship between lean supply chain and I4.0, and for this reason, it should be rejected. Vaguely related ( VR ): Articles which are related only to lean supply chain or I4.0 but not to the relationship between these two should be excluded. Moreover, papers that are just focused on one of these two areas and just briefly mention the other ones were discarded from the literature review. Duplicates ( D ): As it has been decided for the literature to use only one database, Scopus , there are no overlapping results that could be obtained by using different databases. By the way, in the same database, there could be duplicates that must be deducted from the total number of articles reviewed. No access ( NA ): It is possible that in the list of the literature review, there are some papers that could be accessed in terms of title and abstract, but that do not allow to access to the full text. For this reason, these papers should be rejected from the final list of papers. Backward related ( BR ): Some articles that are cited in the articles reviewed should be included in the literature review to deepen the knowledge about the two paradigms under analysis. Forward related ( FR ): Researchers should include publications by the key authors of the two paradigms analysed using the same database, Scopus. Outdated ( O ): Articles published before 2011 should be excluded from the literature review because the paradigm of “Industry 4.0” came up the first time during the Hannover Fair of 2011. Language ( L ): Papers written in a language that differs from English must be discarded for the literature review. A summary of the exclusion and inclusion process with the related numbers is provided in Figure 2 . After the application of the inclusion and exclusion criteria presented above, a final list of papers for the literature review could be identified, first by each researcher independently, before all researchers were able to discuss the list and reach consensus for inclusion in the study. We ensured that researchers had a balance of expertise, for example, one of us has expertise in lean, another in I4.0 and the other in both lean and I4.0. To guarantee future readers to be able to replicate the same search, a record of excluded papers has been kept for their reference (Kitchenham and Charters, 2007). Step 5: Assessing quality According to Whittemore and Knafl (2005), quality standards will differ from one review to another. On one hand, quality assessment is of vital importance for testing reviews, whose aim is generalization. On the other hand, this phase is not important for certain reviews such as scoping reviews, whose objective is to discover the breadth of studies, not the quality. Similar to the inclusion screening process, the authors have performed the quality assessment parallelly, as recommended by Noordzij et al. (2009). Any disagreement has been resolved through discussion and consultation. As it has already been discussed that this literature review can be classified as a scoping review, the type of quality assessment applied has not excluded papers from the pool. This decision is aligned with both the desire to have as much input as possible and the novelty of the topic. Therefore, quality assessment has been an important means for learning the overall quality and distribution of the selected studies. The specifications objects of this assessment are the methodology used to conduct the study and the ranking of the publishing journal. The list of 45 papers including their title, authors, publication year, journal name, ranking and methodology is reported in Table 2 . From Figure 3 , it is possible to notice an increasing trend in the interest for this topic. In particular, it is worth to point out that the majority of papers has been published during past three years, 2018–2020. Looking at the methodologies used for the research ( Figure 4 ), it is immediately clear that 31% of studies have used case study, typically applying this methodology to specific fields. For instance, Ramirez-Peña et al. (2020) focused on shipbuilding, a complex manufacturing industry that needs 4.0 guidelines to improve supply chain efficiency, while Ge and Jackson (2014) investigated usability of Big Data technologies as tools for Six Sigma process to achieve cost reduction in automotive industry. Second, significant number of studies developed a framework connecting the two paradigms of lean supply chain and I4.0. As an example, Bevilacqua et al. (2019) formulated a procedure based on lean principles to minimize the number as well as the duration of picking processes in a warehouse equipped with an automated storage and retrieval system. Then, three studies of the sample used interviews as a way to gather non-structured information to derive insightful findings. Third, 4% of studies exploited the power of simulation to conduct some what-if analysis. Through this technique, Vazquez-Martinez et al. (2018) developed a model that is able to connect different customers, partners and organizations and perform the stages of digital product lifecycle across them. Next, 16% of studies have used the literature review methodology with the aim to describe the state of the art of the literature regarding the interaction and concurrent application of lean supply chain and I4.0. In particular, the purpose of De Giovanni and Cariola (2020) is to investigate how a process innovation strategy that firms implement through I4.0 technologies affect the performance of lean practices and green supply chains. Finally, the survey methodology has been applied by Rossini et al. (2019) among others (22%) to evaluate how the adoption of I4.0 technologies along with LP practices impact the operational performance of European manufacturers. Step 6: Extracting data Generally, the data extraction process often involves coding. As recommended by Gomersall et al. (2015), the researchers have coded the studies independently by reviewing the entire papers, not simply relying on the main interpretation. In this way, it is possible to avoid the distortion of the original paper. The articles were coded to identify the characteristics of each study (e.g. research method) and variables that might be used to explain emergent themes or differences in the works (e.g. interplay between both lean and I4.0 approaches). Step 7: Analysing and synthesizing data Once the data extraction process is completed, the reviewers have to sort out the data according to the previously defined review type (Xiao and Watson, 2017). Each qualitative and quantitative literature identified with the search set through the above steps was again analysed by each researcher independently. Subsequently, reviewers discussed together to translate the quantitative results proposed in the papers to a qualitative output. The approach adopted is the integrated design which analyses and synthesizes quantitative and qualitative research together. Results were synthesized into three emergent groups (again by reaching consensus on the emergent similarities and differences from the literature) – lean favouring I4.0, mutual support of lean and I4.0 and I4.0 supporting lean (see analysis of literature in the following section). Step 8: Report findings In the end, the findings from literature search should be reported after screening and quality assessment in a visual diagram. New insights should be highlighted. In addition, report findings should include also opportunities and direction for future research (Okoli and Schabram, 2010). 4. Results and discussionIn this section, the literature on the interplay between I4.0 and LSCM is analysed. Through literature analysis, 45 articles were identified that directly and indirectly satisfied our criteria and helped us to establish the interrelationships between I4.0 and LSCM. First, an analysis of the literature is presented showing the trend of articles. Then the findings in each of the identified lines are presented followed by discussion. 4.1 Analysis of literatureWe can divide the papers into three main categories: Lean favouring I4.0; Mutual support of lean and I4.0; and I4.0 supporting lean. Table 3 shows the papers based on these categories. Because of the low number of articles and the novelty of the topic, authors defined two research lines that clearly define different approaches to this field of research: strategic and operative levels. The former research line includes all the articles that investigate interplay of the two paradigms focusing on a system perspective, looking at a path of implementation, with long-term period perspective. The latter research line includes all articles that analyse the interplay of the two paradigms at operative level, with a single implementation point of view and short-term perspective linked with the specific practice/technology implementation in a specific context. The details are discussed in the next sections. 4.2 Strategic levelWith the automation provided by I4.0, questions have risen about the interoperability with the lean approach. Lean environment creates a culture more receptive to new technologies, especially the ones that reduce waste ( Bittencourt et al. , 2019 , Torri et al. , 2021). In this sense, LSCM and I4.0, despite different perspectives, should be considered together, as they have the same goal of reducing the costs and increasing the productivity for companies. The authors conducted reviewed this interaction, focusing on the role that lean could play in the ongoing fourth Industrial Revolution. They derived that lean could facilitate to implement I4.0 in the companies, which is also mentioned by Kolberg and Zühlke (2015) . Therefore, the maturity level of lean within a system is an important metric which determines the association with I4.0 (Saxby et al. , 2020). However, the authors stressed the importance of understanding which LSCM elements provide more support to I4.0 introduction. This is necessary to avoid huge investments, both in terms of money and time, for re-inventing operations systems, while a simply update of some element effectively supports I4.0 technologies implementations (Saxby et al. , 2020). The linkage between ICT and LSCM has been confirmed also by Jasti and Kodali (2015) who included Information Technology Management among the pillars of their LSCM framework already presented in the literature review on lean supply chain. Moreover, according to Tan et al. (2002), the information technology is monitoring the information flow within the supply chain, and it is also crucial to maintain and control the multi-organization networks in the present scenario (White and Pearson, 2001). Adamides et al. (2008) highlighted the relevance of ICTs as facilitator for LSCM development if greater integration with customers and suppliers is allowed. Many studies presented I4.0 and LSCM as mutually supportive, where LSCM items are believed to be drivers of I4.0, and I4.0 is thought to strengthen lean (Uriarte et al. , 2018). This insight is also confirmed by Tortorella and Fettermann (2018) that presented a survey study demonstrating that companies who implemented both lean and I4.0 had achieved higher levels of performance improvement than other companies. Chiarini et al. (2020) in their exploratory research on I4.0 technological developments have highlighted the support that I4.0 can provide to LSCM, confirming the results of previous scholars (Kolberg and Zühle, 2015). In particular, they highlight the impact of I4.0 on quality management practices – particularly the emergence of Quality 4.0 concept. However, they also showed some concern about the implementation of I4.0 technologies in an agile and fast-changing lean environment. They suggested that LSCM should be used to remove the waste, which will be a pre-requisite for I4.0 technologies and thereby prevent the automation of waste. The issue of waste is addressed also by Alieva and von Haartman (2020) who focused on the negative impact of inefficient usage of data in the decision-making process on manufacturing performance. In fact, these authors claimed that technological solutions created to gain advantages through data analytics also produce a new form of waste, the digital waste. According to them, digital waste should be considered as a new type of Muda and should encourage to give extra attention to data analytics. According to Ashrafian et al. (2019) , digital lean manufacturing means the application of digital technology in the forms of e-Kanbans or kaizen in digital collaborative environments in an environment where lean is already implemented. It can enhance the lean principles in the form of digitalization that creates less waste. In addition, digitalization in communication is very important for all the partners in the supply chain ( Ashrafian et al. , 2019 ). In fact, strategic supplier development is trying to encourage and enable the suppliers to develop their lean capabilities. It will help them to improve their performance using lean practices (Sako, 2004). Furthermore, the challenges of competitive rivalry have been considered in the development of lean supplier networks. The merits of digital technologies for transforming performance are now widely recognized, and a few contributions can also be seen for connection of digital transformation with LSCM principles (Pinho and Mendes, 2017). However, how digitalization can facilitate or hinder the way in which manufacturing firms use and encourage the development of lean practices with their suppliers is still challenging. Although, despite being complementary initiatives in concept, information technology of I4.0 and LM are not always compatible, companies should try to adopt both in such a way so that sustainable competitiveness can be achieved. The work of Powell (2013) presented ways in which ERP could be used to support LP and pull production, particularly in small- and medium-sized enterprises. In similar fashion, Spenhoff et al. (2021) present challenges and opportunities for lean and I4.0 integration from a technical perspective. As such, we suggest that IT should be adopted to solve real, organizational problems – rather than blindly adopting “sexy” new tech. If firms begin by finding and framing problems, then the solution space for lean techniques, and indeed, digital technologies can be much better explored. In this way, the firms can strengthen the benefits obtained with LM and become more digital and sustainable over time (Mo, 2009). Kolberg and Zühlke (2015) discussed a potential contradiction between lean approach and I4.0 paradigm. The latter stressed the contradiction between lean’s focus on people and I4.0’s focus on the machine technologies. Also, Ruttimann and Stockli (2016) investigated the different role of employee for the two approaches: while lean has historically valued the human resources for their knowledge, I4.0 considers them as a source of variability and potential trouble-shooters in their work interaction with the work carried out by machines. Instead, few authors emphasized total different perspectives and highlighted the potential job enrichment which I4.0 could lead employees, removing physical activities monotony and more intellectual stimulation ( Lagorio et al. , 2021 ). Many authors stressed the relevance of ICTs as necessary elements for managing LSCM operations by not only simply exchanging information with different actors of the supply chain but also establishing an integration with the external partners (Martínez-Jurado and José Moyano-Fuentes, 2014), such as the identification and optimization of value flows. However, Ward and Zhou (2006) found that the information technology implementations used for lean functioning along the supply chains resulted in failures because of the poor infrastructure and communication. Also, different types of information technology have different impact on the lean supply chain. Therefore, Hong et al. (2010) pointed out the importance of categorization of information technology for the supply chain performance. Based on the assumption that the existence of companies totally depends on the long-term competitiveness, Ante et al. (2018) highlighted the relevance of a robust performance indicators system to obtain excellent results. In this context, I4.0 represents a major opportunity, as on one hand it makes easier to analyse machine data, thereby enhancing quality; on the other hand, it helps to avoid faults in the production process. However, the digital revolution has lot of disadvantages for different industries. In fact, I4.0 requires a high level of system control to provide greater flexibility and competitiveness ( Digiesi et al. , 2015 ; Lu, 2017). Then, Ante et al. (2018) designed a key performance indicators tree to connect the key performance indicators with the improvement measures in an efficient manner. The KPI tree is divided in a five-level hierarchical structure: the Value Contribution, the Key Performance Result (KPR), the Value stream KPRs, the Monitoring KPRs and the Improvement KPRs. These structures help to monitor I4.0 projects as well as to drive the lean continuous improvement process. 4.3 Operative levelIn a different branch of literature about interplay of LSCM and I4.0, authors have focused on specific I4.0 technologies and applications and their links with specific LSCM items. According to the study of Ramirez-Peña et al. (2020), to properly implement I4.0, the supply chain must be lean. In fact, I4.0 technologies can play an important role for different actors of the supply chain. Simulation is one of them, as highlighted by Rossini and Staudacher (2016) that conducted a study through simulation to understand how lean techniques can improve the performance of supply chain planning. Artificial intelligence has proven to be connected to lean supply chain by Haq and Boddu (2015) , who presented a fuzzy logic model incrementing significantly the efficiency of the system. According to Ahmed et al. (2018) , Big Data impacts the supply chain management from the environmental point of view. Ramirez-Peña et al. (2020) investigated and found out that Autonomous Robots, Additive Manufacturing, Cybersecurity, Cloud Computing and Augmented Reality are the most relevant to improve Green LSCM items. With a similar perspective, De Giovanni and Cariola (2020) investigated the impact of I4.0 technologies implementation on lean and green practices in supply chains. The authors stated that process innovation via I4.0 technologies does not lead to relevant effect on green performances, while it makes lean practices more effective for improving operational and economic performance. Roy and Roy (2019) previously described in the literature review on I4.0 about developing their Smart Management System (SMgS). The new technology-based SMgS will help the industries to become more efficient, sustainable, lean, safer and cost effective. In particular, “Lean and Efficient” shows up between the benefits of the system, meaning that SMgS can be used faster with less difficulty compared to lean philosophy but leads to the same results. In fact, the system integration will make the operation lean and efficient by removing wastes ( Heikkilä, 2002 ). Instead, recently, few authors investigated the evolution of a traditional LSCM elements, such as Kanban, with the introduction of I4.0 technology. In particular, they focused on the implementation of a CPS and on the consequent benefits on the Kanban aiming to automate with limited or no human interaction. The “e-Kanban” is based on a virtual system; the traditional card is evolved in a digital card and is transmitted electronically. The e-Kanban replaces traditional Kanban cards with barcodes; it exploits the technology to improve the movement of material. The e-Kanban reduces human effort for managing the card, and it provides real-time availability of all relevant Kanban information, directly linked online with the Cloud. Bevilacqua et al. (2019) stated that, with the current manufacturing environment moving towards a 4.0 perspective, there is a growing focus on Big Data Analytics techniques. Indeed, data understanding represents a key aspect for extracting useful knowledge and new information with the aim of taking advantage from them. These authors claimed that like lean manufacturing, manufacturing automation also has the goal of satisfying the customers at the possible minimum cost. Manufacturing automation addresses the removal of nonvalue-added activities and produces predictable quality to achieve these goals. In this scenario, Big Data Analytics methods help to communicate between automation and LP approaches ( Bevilacqua et al. , 2019 ). Vazquez-Martinez et al. (2018) presented a new distribution model with the name CloudChain, inspired by LSCM principles and useful for digital products supply chain. In the model, I4.0 technologies create secured containers and operations network configuration that supports transportation activities. Managers can configure CloudChain as a traditional packing and logistic service but exploiting I4.0 potentials. This distribution model aligns applications of multiple partners involved in the supply chain, both upstream and downstream, and supports the design of value chains with continuous information flows through different cloud storage resources (Vazquez-Martinez et al. , 2018). Earlier Blockchain, the leading technology layer, is used only for financial applications. But since the past few years, the research trend for Blockchain technologies is shifting to other domains; in particular, Perboli et al. (2018) have investigated the application of Blockchain in supply chain and logistics. Ensuring data immutability and public accessibility of data streams make the Blockchain a disruptive innovation. Moreover, the decentralization structure of the Blockchain overcomes the issues that occurred in the centralization structure, including trust issues. However, since its inception, Blockchain has some inherent defects, which need to be addressed before its deployment to other sectors. Anyhow, the adoption of the Blockchain technology can represent the backbone of a new digital supply chain. Together with the other technological aspects, such as Business Analytics and artificial intelligence, it has contributed to the rapid evolution of logistics in the past decade. Blockchain can be used to overcome the security challenges in Internet of Things. As, as highlighted, Blockchain can break down some barriers of I4.0 technologies along the supply chain, it can favour the integration of the lean philosophy and the I4.0 in the supply chain. Ge and Jackson (2014) focused on the newest adoption of Big Data to minimize cost in the automotive sector. Authors identified Big Data application beneficial proactively minimizing cost and reactiveness. Moreover, Big Data technologies can enable automotive companies to develop circular economy. Some of the benefits provided by Big Data are also supportive of other existing methodologies used in the automotive engineering domain such as Continuous Product Improvement methodologies. Based on Plan-do-check-act, DMAIC is one such Continuous Product Improvement methodology. The successful usage of Big Data technologies for the DMAIC process suggests that they might work more efficiently in aggregating data, in performing preliminary analysis and increasing the support that DMAIC methodology could give high-level decisions. Therefore, there is room for the complementary usage of lean techniques and Big Data in terms of both cost reduction and optimization of high-level strategies. thorough understanding of the customer demand; rapid exchange of the demand data throughout the complex supply chain; faster smart factories production with less waste; much quicker one-piece flow of customized products; potential to radically reduce inventories throughout the supply chain; real-time information sharing through coordination in the entire supply chain; and radically improvement form of instant just-in-time pull production reducing/eliminating overproduction (Netland, 2015). Rossini et al. (2019) examined the impact of the association between lean adoption and I4.0. Authors highlighted that, of the 16 main I4.0 technologies found in the literature, “big data” and “augmented reality” were the most common. On the other hand, “Collaboration with suppliers/customers through real-time data sharing” seems to be scarcely investigated in the I4.0 literature. This justifies the fact that a lower emphasis is given on the studies related to I4.0 for customers/suppliers relationships ( Rossini et al. , 2019 ). This insight is notably important for the purpose of this analysis. In fact, this study provides some answers to the interrelationships between I4.0 and lean at the operation level of supply chain context. Haddud and Khare (2019) investigated the impact of digitalization in supply chains and suggest that they may provide benefits in a lean environment. More specifically, the study examined the potential impacts of seven enabling digital technologies ( Meier, 2016 ) on five selected lean operations practices that are JIT, Visual Management, Total Productive Maintenance, Continuous Improvement and Autonomation (failure prevention) and Poka-Yoke (mistake-proofing). The digitalization in supply chains was shown to have an enormous impact on all the five lean operations practices mentioned above. 4.4 DiscussionThe SLR clearly shows that LSCM and I4.0 support each other in a synergistical perspective. As I4.0 technologies enhance LSCM practices with the digitalization of traditional LSCM items, LSCM practices work as enablers for the introduction of I4.0 technologies in the supply chain system. This mutual support is perfectly aligned with the most part of recent research about interplay between lean system and I4.0 ( Buer et al. , 2018 ; Núñez-Merino et al. , 2020 ). However, some more insights clearly emerge. In fact, if it is out of discussion that LSCM and I4.0 mutually support each other, then this slightly changes while we split analysis from strategical and operative level. The operative stream of research mainly focuses on presenting the positive impact of LSCM practices digitalization, or the support that the introduction of I4.0 technologies gives to traditional, and sometime old, LSCM practices. On the other face of the coin, the strategic stream of research mainly focuses on proposing LSCM paradigm as necessary base for the introduction of I4.0 technologies, because of the goodness of the operations supply chain system and the guideline principles for the correct choice of investments. With these perspectives, there is a clear trend of what supports and what is supported, as shown in the framework presented Figure 5 : at strategic level, LSCM supports I4.0 because it drives I4.0 introduction, but at operative level, I4.0 supports LSCM because it enhances LSCM practices. This framework adds a piece of knowledge of the literature of the interplay between LSCM and I4.0, but at the same time, it could support in understanding more in general the interplay between lean and I4.0. It is coherent with all the research works that presented a positive correlation between lean and I4.0 ( Rossini et al. , 2019 ; Tortorella et al. , 2021 ). It supports the literature of synergic perspective of the two paradigms ( Buer et al. , 2020 ), given a clearer positioning of the role of the paradigms. This fact is also supported by the recent literature where specific I4.0 technologies are adapted with lean techniques from the simple 5S to the more sophisticated SPC and Total Productive Maintenance systems (Chiarini and Kumar, 2020; Bittencourt et al. , 2021 ; Ciano et al. , 2021 ; Raji et al. , 2021; Spenhoff et al. , 2021 ). At strategic level, lean supply chain is driving I4.0 by streamlining different entities of supply chain to reduce waste. This is particularly true with regard to the greater horizontal and vertical integration enabled by ICT in I4.0, for example, the Industrial Internet of Things, Digital Twin and advanced IT infrastructures which build on more traditional ERP systems. According to lean, once the value is defined for the customers, the situation is mapped within and across organizations, to find the nonvalue-adding activities that have to be eliminated. The value stream mapping is also supported by I4.0, but importance will be given to digital environment rather than the physical environment. At the operational level, continuous flow is one of the key lean elements. The production process must maintain the takt time agreed with the customers. Instead of physical entities, I4.0 aims to make the data stream flow according to the real time. Again, we see that digital technologies such as Big Data Analytics and digital twins, as well as tools that support the worker such as augmented reality, virtual reality and smart wearables, will in fact contribute to enhanced lean practices. The final objective of lean is to produce only according to the time and specifications provided by the customers. In addition to the products, I4.0 makes the customers to pull the essential services related to the product. This will help to improve the customer satisfaction. Therefore, the smartification of products using Radio Frequency Identification will provide an evolutionary impact of I4.0 in favour of lean principles. In the following paragraphs, the theoretical and practical implications of the study are going to be discussed. 4.5 Theoretical implicationsTo the best of our knowledge, this paper represents the first structured analysis regarding the interrelation between LSCM and I4.0 in the literature. Indeed, currently, in literature, there are several papers focused on this argument, but they are not totally comprehensive. Therefore, this study represents the fundamental starting point for those academicians that want to develop further advanced researches in the field of LSCM and I4.0 environments. The outcomes achieved through the analysis developed in this paper confirm the role of I4.0 practices in a LSCM environment. At the strategic level, LSCM influences I4.0, whereas I4.0 in the LSCM enhances integration and information flow with customers and suppliers, especially horizontal and vertical integration, CloudChain, Big Data, etc. Additionally, this paper attaches an active role of I4.0 regarding continuous improvement, which is a salient feature of lean. Thus, this confirms the knowledge direction supported by the previous studies by Ward and Zhou (2006) and Adamides et al. (2008) . Hence, in this paper, the academicians can find the reasoning behind the school of thought in the literature that sustain the existence of a mutual beneficial partnership between LSCM and I4.0. Moreover, each relationship that exists between these two paradigms and the detailed explanation of these connections can by analysed by academicians. 4.6 Practical implicationsFrom a managerial point of view, this study investigates the interactions between LSCM and I4.0 providing a twofold and complete point of view. On one hand, it offers suggestions on the action plan to follow if a firm is already implementing the lean paradigm along the supply chain and wants to begin a new project involving the I4.0; on the other hand, it represents a guideline for companies already adopting I4.0 and seeking to begin to implement also some lean concepts. The understanding of the implications of I4.0 and its expansion to the supply chain level will help companies to properly adopt the LSCM and the I4.0 paradigms concurrently. The lack of knowledge about the potential benefits or uncertain outcomes of investments has many times prevented many companies to implement both LSCM and I4.0. But the findings from this research are suggesting to concentrate more to develop LSCM given its high importance in driving the improvement in I4.0 paradigm, not only fostering the adoption of other practices but also reducing the barriers of I4.0. Moreover, the framework can act as a decision-making tool for the companies to obtain maximum benefits while implementing LSCM and I4.0 together. Another practical implication that is worth to point out regards the I4.0 practices and in particular the characteristics of the most relevant practices according to the influence that they can exert on other practices or on the barriers. Finally, to make I4.0 a success in LSCM internally and externally, the government or the public sector should come forward and take into consideration the findings of this research as a reference to promote a roadmap transition towards the adoption of I4.0 and LSCM. 5. ConclusionFor many years, the philosophy of lean thinking and its principles offered a way for practitioners to build an efficient and competitive production system. Success by success, lean management is slowly becoming relevant for improvement in supply chain, that is, LSCM. On the other hand, I4.0 appeared more recently as a revolution, offering potentials of improvement in quality, flexibility and productivity exploiting the digital technologies. Thus, it comes into doubt about the relationship between the two paradigms, whether they are coherent or they are opposite, they are alternative or complementary. In this context, we provide a framework which suggests the interrelationship and interplay between the two paradigms. The starting point of the research has been to collect the information about the two paradigms under analysis, LSCM and I4.0 that were available in the current literature. Then, the authors have investigated through a SLR the relationships between the two paradigms. It is observed from the literature that there is an increasing trend in papers which are discussing about both importance of lean and I4.0. From the literature analysis, it is possible to categorize the interrelationship between LSCM and I4.0 in two directions: strategic and operative levels. At the strategic level, LSCM is driving I4.0 to build sustainability and diverse demand of the customers is thriving for Digital LSCM. At the operative level, I4.0 is supporting LSCM in terms of advanced tools and techniques, like Big Data, Augmented reality, Digital products, CloudChain, Blockchain and additive manufacturing. The main contributions of this paper are the identification of the research lines developed from the literature analysis; an understanding of the interrelationship between LSCM and I4.0 and an exploration of the most relevant areas where the greatest effort has to be made. An overview of the limitations of the research and some suggestions about the direction of further studies are presented below. 5.1 LimitationsConsidering the interrelations between LSCM and I4.0, the discussed results have contributed to enhance the knowledge in this field both in terms of theoretical and practical implications, as mentioned above. Nevertheless, this paper is not exempt from limitations, as any other research paper. Starting from the SLR performed, the authors have included only one database, Scopus. According to this, there might be additional knowledge about the relationship between lean supply chain and I4.0. Therefore, considering different databases, such as Google Scholar and Web of Science, or a combination of more than a single database could bring different information. Furthermore, it has been difficult to detect practitioners that are applying the two industrial paradigms in the boundaries of their firms or, at least, that are experts of both LSCM and I4.0. This aspect demonstrates the novelty of the argument covered with this paper. 5.2 Future scopeGiven the novelty of the paper, it could be considered as a preliminary analysis for further advanced researches regarding the relationships between LSCM and I4.0, as highlighted in the theoretical implications. Therefore, the authors have identified several further improvements for future possible complementary studies. To increase the knowledge in the literature, relevant results could be obtained considering only firms that are currently applying LSCM and want to start the journey with I4.0 or vice versa. In this scenario, a case study could be developed to understand the practical implications of the simultaneous application of both paradigms and to validate the theoretical results obtained. A possible future step can involve the application of the framework of analysis developed in this paper on specific situations, that is, considering a specific industry, company size or geographical location. Indeed, considering a small- and medium-sized enterprise or a large enterprise could bring different outcomes in the simultaneous adoption of LSCM and I4.0. Finally, because of the novelty of the argument and the significant importance that this argument is achieving nowadays, these types of analysis would need to be replicated after few years. Literature review methodology Literature review process Yearly distribution of the papers considered Methodology distribution of the papers considered Relationship between lean supply chain management and Industry 4.0 Research keywords used

Selected papers for systematic literature review

Literature details