Safety – Safety moment topics for oil and gas

Safety moment topics for oil and gas companies and workers

What is a safety moment.

A safety moment is a short and concise safety talk in the workplace. Each safety moment will cover a specific safety topic relevant to the workplace and environment in which it takes place.

Many companies engage in safety moments - while others have slightly different variations (which are almost identical) including safety toolbox talks and safety briefs.

The main purpose of a safety moment is to draw attention to a relevant safety topic and to discuss that topic in an informal and approachable way.

Safety moments have become extremely popular with an ever-increasing growing focus on safety, and they have also grown in popularity as a powerful tool for improving worker safety. There was a time when most companies and workers would only engage in a formal workplace safety training session - or when safety training was a short part of a workers induction.

Today, safety training is a constant, and safety moments are one of the ways in which companies and workers can constantly refine their understanding and attention to safety - and where an entire organisation can work on building a positive culture of safety.

Safety moment topics for oil and gas

The oil and gas industry is filled with safety moment topic options and opportunities - which is a good and bad thing. It makes coming up with safety moment topics pretty easy - but highlights the dangers of the industry.

While there are hundreds of safety moment topics and toolbox talk topics like these:

- First aid safety

- Lock out tag out safety

- Vehicle safety

- Traffic safety

We are going to focus on safety moment topics which are more specific to the oil and gas industry. The key element of a safety moment is that it is highly relevant to the workplace at issue. You want your safety moments to be as relevant as possible, to keep people engaged and to ensure there are actionable and insightful takeaways for the attendees.

Here are some safety moment for oil and gas topics which are applicable to almost all oil and gas sites and projects - and ones which you need to cover for oil and gas safety.

Chemical exposures

Oil and gas sites and platforms almost always feature a certain amount of chemical exposure. Chemical exposure is also one of the areas of industrial worker safety which is less pronounced and understood than other safety issues such as working at heights and personal protective equipment. The general consensus is that there is a lack of exisiting information and understanding regarding the variety and magnitude of chemical exposure to oil and gas workers.

Important elements of this safety moment topic include:

- Documenting and understanding hazardous chemicals via labels and material safety data sheets

- How to deal with episodic exposure

- The difference between mixed exposures, multiple exposures and dermal exposures

- The risk of transfer risks and take-home exposures

Hazardous chemical exposure is a very real and ever-present danger for oil and gas workers, and the fact that it is more 'invisible' than other safety issues makes it even more important to talk about.

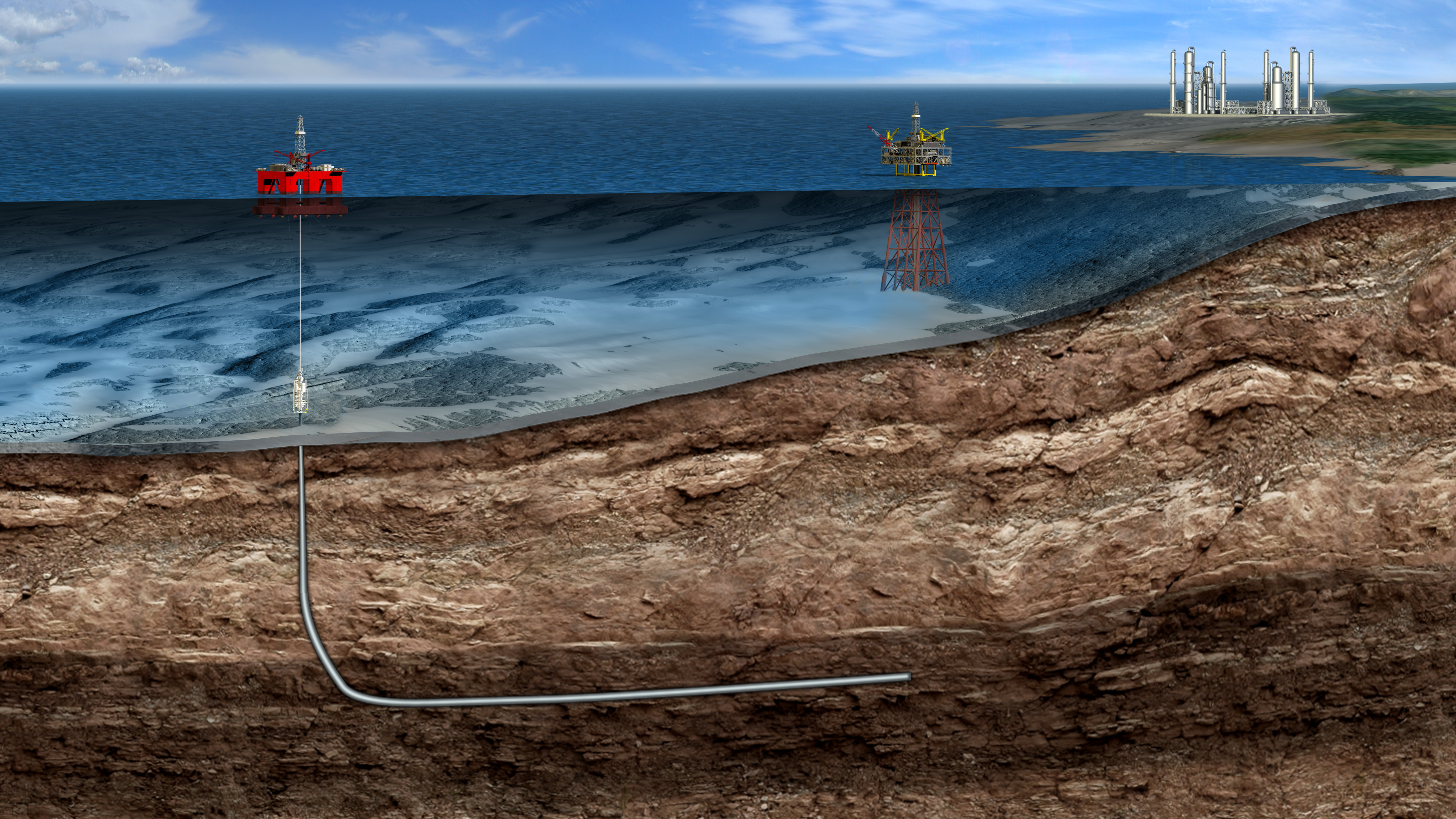

Working in remote areas

Working and travelling to remote areas is an inherent part of working in the oil and gas industry. Offshore oil and gas fields, onshore gas pipelines which are remotely located and other characteristics of the oil and gas work make it very common for workers to be working alone and/or working remotely.

Working in remote areas introduces a number of safety concerns and hazards which should be talked about and discussed during a safety moment.

In these remote areas, workers face harsh conditions and environments, they must drive/travel long distances and frequently off-road, and if an incident does occur, they are effectively stranded and must find a way to communicate the issue.

These and other nuanced elements of remote or lone worker safety like how much water to carry (more than you think) make for a good safety moment.

Explosions and fires

The oil and gas industry has more deaths from fires and explosions that any other industry. Explosions and fires are the most violent and 'obvious' and publicised hazard which oil and gas workers face. Even so, discussing and constantly reinforcing how to prevent and manage explosions and fires can be the difference between life and death.

During this safety moment topic, you'll want to cover:

- How to prevent fires and explosions from happening

- Designated exit routes and emergency action plans

- Flame-resistant clothing and other safety equipment

- How to inform and collaborate with first responders

This is a topic which can be re-visited multiple times, because it's so important.

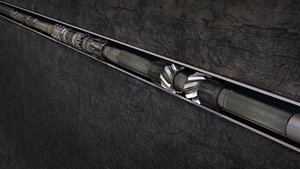

Struck-by, caught-in and caught-between

Like construction and a number of other heavy industries, oil and gas workers suffer from being struck-by, caught-in and caught-between vehicles, machines and other obstacles at scary rates.

Part of this stems from the fact that there are many moving parts on oil and gas projects and sites (including people) and part of it stems from the general environment (such as close-quartered platforms and drilling sites).

Some of these issues will occur, but some of them can be mitigated and reduced through a better understanding of how to approach different struck-by, caught in and between hazards - which is why this safety moment is helpful.

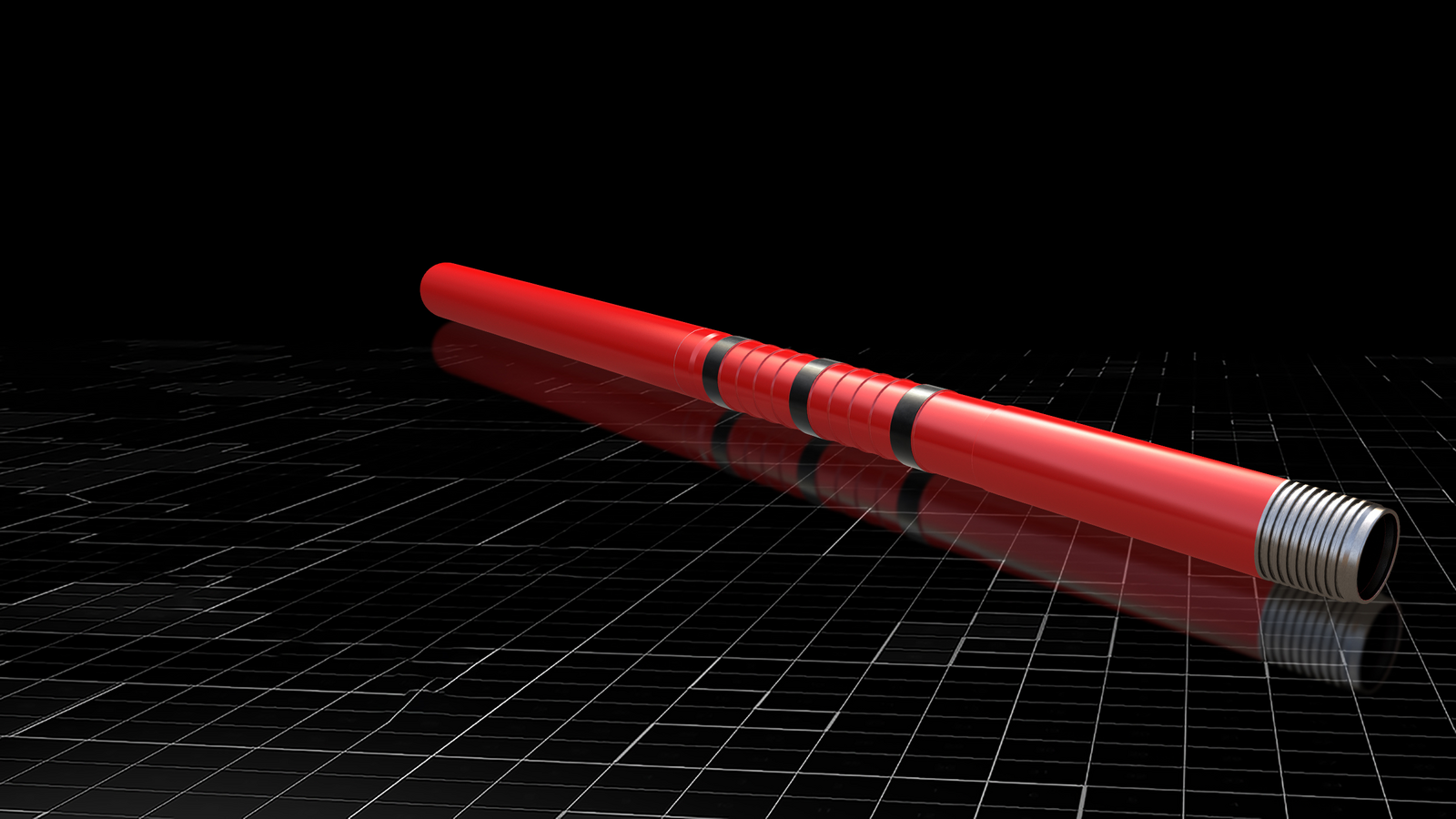

Drilling is an integral part of excavating oil and gas out of the earth, and drilling and drill pipe assembly and disassembly are a constant hazard to oil and gas workers.

Every step of drilling carries it's own risks and hazards, and each can be brought up and covered in a safety moment - or each may deserve its very own safety moment.

Some key elements of drilling safety to cover in your safety moment include:

- Handling pipes correctly

- Preparing drilling fluid and starting to drill

- Breaking out pipe and making up pipe

- Raising the kelly and joint out of the mousehole

While workers engaging in these activities have a thorough understanding of how to perform these processes and procedures, a safety moment is a great chance to get everyone involved and have people actively discuss their own experiences and incidents while drilling. Crowdsourcing this information is a powerful way to uncover more hazards and more ways of dealing with drilling and pipe assembly dangers.

Pressure test

We've all seen and understand the immense pressures being forced up into, down into and across pipes and platforms in the oil and gas industry. High pressure can be a lethal force, and discussing the dangers and realities of these pressures is a perfect subject of a safety moment.

Pressure testing may be a routine task for oil and gas workers, but pressurisation is hazardous energy storage, and requires adequate preparation. Key areas to cover in this oil and gas safety moment include:

- Test permitting

- Pressure test checklists

- Roping off test areas and coordinating to avoid concurrent activities

- Never tamper with or righten fittings while the test is underway

- Removing non-essential people from the test area

Engaging in this safety moment for oil and gas topic is important for testers, and important for those who are working anywhere on site.

Oil and gas safety moment topic example

So now that you have seen and read about some important safety moment topics for oil and gas workers and companies, what does the actual safety moment look like?

A good practice for conducting safety moments, like most things on oil and gas sites, is to properly document the safety moment or toolbox talk.

The oil and gas safety moment example below covered the topic of working in remote areas.

You'll see that this form was used to summarise the topic and discussions, as well create some actions to be taken and responsible people for those actions.

A great part of safety moments is the approachable and informal nature of them - but it's also important to turn those discussions into actionable items which improves worker safety.

If every safety moment you engage in is actioned, then it's inevitable that oil and gas project and worker safety will improve.

Use this safety moment framework for your own safety moment topics and talks.

How to choose the right safety moment topics for your oil and gas operations.

As someone who works in the oil and gas industry, I'm sure you are more than aware of the hazards facing oil and gas companies and workers every day.

In looking for safety moments for oil and gas projects and sites, it's important to leverage this experience and understanding of the industry with the most applicable safety moments today.

Applicable can mean that there was a recent incident or near miss, it could be covering a new technology or technique which gives rise to a number of new risks and issues, or it could be conducting a safety moment which is hyper contextual to the project, site or workplace in question that day.

You want your safety moment topics to be as engaging and relevant as possible in order to encourage maximum engagement and participation from team members. If you're looking to standardise your safety moments process, consider using this safety moments app .

Safety moments are an easy and fun way for teams to come together to discuss and create strategies about how the site can be safer - and how they and their fellow site workers can stay safe in the face of the obvious dangers that the oil and gas industry continue to throw their way.

Safety Toolbox Talk template

See the template →

Risk Register for Oil and Gas template

People in 80+ countries use this safety management system to improve their safety processes and outcomes.

See how you can easily streamline your systems and processes with Sitemate today

About Lance Hodgson

Lance is VP of Marketing at Sitemate. His aim is to bring awareness to a brighter future for the Built World where industrial workers and companies work smarter.

Leave a Comment Cancel Reply

Save my name, email, and website in this browser for the next time I comment.

Safety Alerts & Moments

Improving safety through collaboration, learning and sharing experience

Submit an Alert

If you have seen an example of good practice or know of a safety incident the industry can learn from we want to hear from you. Your submission will be reviewed and anonymised before being published.

Get Started

Step Change in Safety is committed to working with the UK oil and gas industry to continually improve safety and make the UKCS the safest oil and gas province in the world in which to work.

An essential part of that mission is learning from previous experiences through collaboration. Our searchable catalogue of hundreds of Safety Alerts and Safety Moments are all designed as learning resources that can help improve workplace safety. All contributions remain anonymous to encourage sharing within the industry. No company names, platforms, fields, locations, dates and individuals are referred to in our Safety Alerts and Moments.

Safety Alerts give details of events surrounding an incident or near miss and provide good practice guidance in order to prevent similar issues. Safety Moments are downloadable PowerPoint presentations detailing an incident, near miss or good practice, and which provide discussion points and related resources for use as learning tools.

Search for safety alerts and moments

Play your part in improving workplace safety. Browse our extensive catalogue of Safety Alerts and Moments to learn from the experiences of industry colleagues.

Featured Alerts & Moments

Water injection over-pressurisation

When would you shut down?

Major Accident Hazard Awareness

Search alerts & moments, cause & consequences, contributing factor, manual handling - person in line of fire.

A warehouse and yard worker was rolling a flex stabilizer on a sawhorse rack. One end of the tool dropped from the rack, causing the…

Person injured during lifting of compressor

A worker was crushed by heavy equipment under maintenance, when the vessel rolled slightly. On a very large vessel, a team of specialist…

Personnel exposed to hydrogen sulphide during maintenance

Subcontractor personnel were exposed to a high concentration of Hydrogen sulphide (H₂S) for a short period during maintenance work in a…

Carriage of Methanol - Dangerous Goods - without proper certification

Methanol was being transported from place to place offshore, without appropriate Dangerous Goods certification. Methanol is very flammable.…

Dropped welding fume extraction hood

During pipelay activities onboard a vessel, a welding fume extraction hood (which weighed 215kg) fell onto a work station below. A crew…

Swinging load after loss of position

During backloading of an empty refrigerated container to a Pipe Supply Vessel (PSV), adverse weather conditions, combined with technical…

Be the first to receive our news and alerts by signing up to join the Step Change in Safety website

Register Now

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

SAFETY IN OIL AND GAS INDUSTRY.pptx

Safety is the key factor allowing companies to operate efficiently and without danger on the worker. The unsafe act and unsafe conditions are the main causes of accidents which may result into a minor or major fires, harms and other consequences. After the accident, the company may suffer from loss of production and profit and that is very dangerous as known in the rules of each company.

Related Papers

MOHD RIZUAN BIN ISMAIL (JTM-ILPTANGKAK)

Chemical Engineering & Technology

Saily Costa Ramos

CRC Press eBooks

Dhananjoy Ghosh

International Journal of Petroleum and Petrochemical Engineering

Sunil Jayant Kulkarni

Achal Garg , Harinder Yadav

Following the disastrous accident of 20 April 2010 in the Gulf of Mexico, where an explosion on drilling rig Deepwater strata, exploring oil and gas at the Macondo well about 60 kilometer offshore the US coast, caused the death of 11 workers and severe injuries to many others including massive sea pollution from the release of 5 million barrels of crude oil. As it has been dramatically demonstrated not only in the Macondo well accident but in a variety of cases, offshore oil rig activities entail the hazard of a major accident with potentially severe consequences to the life and health of workers, pollution of the ecosystem, direct and indirect economic losses, and deterioration of the security of energy supply. While consequences of potential accidents to life and health of the workers, environment and especially of the neighbouring coastal areas, and direct economic damage are direct effects and can easily be assessed, indirect economic loss and outcomes of the accident to security of energy supply are more difficult to be assessed accurately. After a first brief reference to the obstacles related to the exploration and production activities in oil and gas rigs, the analysis goes to the existing sources of information and their availability to the public. The primary objective of the study is to analyse the safety aspects of the offshore operations in oil and gas industry with an assessment of the resources available for accident analysis and information based communication for offshore.

Safety Science

Kuok Ho Daniel Tang

Beshoy Safwat

This project examines the factors that influence the safety culture in companies of the oil and gas industry. The project highlights and identifies the important factors that affect the safety culture in the oil and gas industry and based on the findings from past researches and a field study, a model of safety culture will be developed. The report explains in details the review of 48 literature and case studies that are related to the safety culture of companies in different industries but mainly from the oil and gas industry. The literature studied the factors that affect the safety culture and identified the factors that contributed to the occurrence of major accidents

IAEME PUBLICATION

IAEME Publication

Hydrocarbon Industry stands any country’s backbone for social strength and economic development. The oil and gas industry provides variety of products that help people in daily life everyday hence it is very important to tackle the problems faced during the operation of a drilling rig in order to prevent wastage of time and money as well as huge accidents like kick followed by blowout may take place. The literature is evident to say that there is not only high risk to personnel working in field but also to environment and assets in Oil & Gas Operations. As per the report of IOGP (International Association of Oil and Gas Producers) it is observed that percentage of accidents is second highest in drilling domain. The occurrence of accident pattern in Oil & Gas industry is to be considered otherwise than the traditional accident occurrence theories. Largely the causes of accident in hydrocarbon industry is due to failure of barriers which are primarily related to human behavior. Hence this research aims to propose a framework to understand the various factors like personal factors, job factors and unsafe acts and condition that affect the safety because of human attitude. Later a program is designed names Safety Awareness Program (SAP) by targeting the employees of various oil companies in Oman which will act as a moderating variable to know the impact of it at employee level such the work performance, individual performance is improved with results of accidents/fatalities in the industry if not the loss will occur if wrong decision might be taken, the loss of billion and trillion dollars. The detailed analysis is done by self-structured questionnaire

TENGKU NURUL AISHAH TENGKU AZIZ

Noma Ogbeifun

PresentationInherent safety is not a new concept and is recognized in the oil and gas industry following the works of Trevor Kletz [1] and others dating back to the 1970s. However, despite the progress made to date in the process safety management arena, incidents have occurred resulting in a renewed focus by regulators to follow-up with more stringent regulations. Two recent studies, covering a span of 20 years (1998-2018), revealed that 19-36% of these incidents could have been avoided if an Inherent Safer Design approach was utilized [2]. Some barriers to adoption and implementation of inherent safety include lack of full understanding of Inherently Safer Design (ISD) principles, lack of assessment tools to showcase ISD benefits, and lack of ISD application framework. This paper will demystify ISD definition, examine the barriers to ISD application, propose a framework to overcome them and share recent successes in application of ISD at Chevron

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

RELATED PAPERS

International Journal of Engineering Research and Technology (IJERT)

IJERT Journal

Procedia Engineering

Organization, Technology and Management in Construction: an International Journal

Emmanuel Abeku Essel

MD MEHEDI HASAN RAYHAN

journal johe

Phillip Harrick

IJERA Journal

Dr.Osama Lamma

Hortense Blazsin

Wameedh Khdair

Eric Danso-Boateng , Osei-Wusu Achaw

Akash Rana Samir Rana

International Journal of Advanced Research in Computer Science and Software Engineering

Arvind Rehalia

Sandra L Beltran , Rodolfo Vilela

Open Journal of Safety Science and Technology

OLUWASEUN FAREMI

Academy of Management Discoveries

Charles Cowley

Prof Chaminda Pathirage

Elsevier eBooks

Hans Pasman

IJSRP Journal

Meraj Ahsan

Christopher Oghenerioborue

DR MOHD FARIS KHAMIDI

Journal of Loss Prevention in the Process Industries

Ignatius Prashanth , Dr Raju Ganesh Sunder

Iranian Journal of health, Safety and environment

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

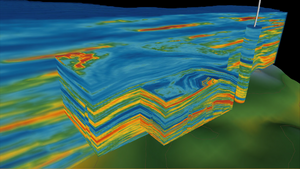

High-quality well data when it matters most

Mitigating deepwater and subsea formation evaluation challenges

Enhanced subsurface insight, superior drilling performance, and consistent well delivery

Curing severe to total losses while drilling to achieve zonal isolation

Improving drilling performance with the LOGIX® autonomous drilling platform

High-performance water-based fluids and additives customized to meet your specific challenges

Monitoring solution for continuous data of the subsurface

Powering a new era in hydraulic fracturing

Robust and reliable liners for onshore and offshore installations

Design and monitoring expertise to digitally transform ESP performance

Combination of probes, chemistry, monitoring, and automated control delivers significant savings

Decisive insight for optimal well intervention and integrity

Safely plug wells and help prevent carbon emissions

Drill Tech® and RTTS® enable wellbore cleanout test in single trip

Integrated approach for wellbore cleanup and displacement

Subscription service solution for ultimate well control

Integrated service solution delivers first onshore ERD well and longest onshore well

Develop new, mature, and unconventional fields efficiently

Enterprise scale deployment of tried and tested E&P software

Providing unparalleled decision-making capabilities under uncertainty while drilling

Deploy, integrate, and manage sophisticated E&P cloud applications

- Halliburton

- About Halliburton

- Health, Safety, Environment, and Service Quality

Safety is everyone's business

Every person on every Halliburton team is tasked with taking personal ownership of their own safety and looking out for others.

Safety is our conversation starter

We start every meeting at Halliburton with a relevant safety moment. This prioritizes safety and sparks thinking and discussion about following safe practices in the workplace, job site, and beyond. These engaging discussions often lead to new safety moment ideas, which help protect our employees, customers, and their work environments.

Halliburton safety moments are popular within our company, in oil and gas, and in other industries. Explore our library and share these ideas with your teams to help keep more people safe.

Halliburton Life Rules, adopted from the International Association of Oil and Gas Producers (IOGP), serve as categories for many of our safety moments. Safety moments that our hardworking employees have created that don’t correspond to a Life Rule are categorized as general safety moments.

Bypassing Safety Controls

When working with chemicals or dangerous equipment, following safety controls is imperative. To prevent injuries and reduce health risks, our employees must obtain authorization before overriding or disabling safety controls.

Confined Space

The confined space safety moments remind employees to exercise extreme caution when confined spaces are involved. Halliburton employees are trained to always have personal protective equipment, an exit strategy, and other procedures in place before obtaining authorization to enter a confined space.

Safety moments for driving help prevent accidents and keep our employees and those around them safe. We remind Halliburton employees to avoid becoming distracted or fatigued when behind the wheel and to be attentive when driving in school zones.

Line of Fire

Many hazardous conditions can put employees in the line of fire if they are not handled properly. Line of fire safety moments provide guidelines needed to stay safe when securing loads, handling and lifting tubular equipment, using hand tools, and other common hazards.

Safe Mechanical Lifting

Lifting equipment requires planning and situational awareness. Employees must follow specific instructions when working near a forklift, lifting heavy loads, and using lifting equipment. These safety moments help keep everyone near a lift and involved in lifting out of harm’s way.

Work Authorization

A facility-issued permit to work is ideal for high-risk, non-routine jobs. Performing a risk assessment and acquiring an approved permit to work helps mitigate risks to our employees when they are grinding and welding or working in confined spaces where atmospheric and chemical hazards may exist.

Working at Height

Taking precautions when working at height is taken seriously to protect team members from life-threatening falls. These safety moments equip employees with reminders and information to prevent equipment malfunctions, choose the safest gear, and stay secure while working above ground level.

With safety as our top priority, we want people to come to work feeling prepared for any situation. General safety moments share best practices on how to stay safe while working in high temperatures and humidity. They also reinforce that we encourage every employee to help correct unsafe situations when they spot them.

Oil and Gas Industry Toolbox Talks

Browse a few of our oil and gas safety toolbox talks below for free. No email address is required. These short one to two-page safety topics focus solely on the oil and gas industry. All of the talks were written by an oil and gas safety professional who has been in the field for over twenty years.

Free Oil and Gas Talks

Below is a list of five of these talks. There are over 40 oil and gas-specific safety toolbox talks found on the Members site, with more being added in the coming months. There are additional free safety talks that relate to the oil and gas industry in a general sense, which can be found by clicking here .

- Lube Oil Flushing

- Filter Pot Sock Filter Changeout

- Hose Parting During Pneumatic Testing

- Spill Prevention

- Glycol Reclamation

At the bottom of this page is a complete list of the oil and gas safety topics that are currently available for Members .

Why Safety Matters in the Oil and Gas Industry

Working in the oil and gas field can be a fulfilling and lucrative career path. That being said, employees are exposed to a multitude of hazards that can lead to significant injuries, illnesses, and deaths. Everything from struck-by incidents, burn hazards, equipment failure, moving equipment, pressurized systems, etc., are everyday sights for those who work in this field that is critical to our infrastructure.

To mitigate the hazards of this work to acceptable levels, a variety of different types of safeguards need to be used. There are different levels of effectiveness of safeguards that can be utilized to keep workers safe. The most effective safeguard is elimination of hazards followed by substitution, engineering controls, administrative controls, and PPE.

While the first choice in safeguards should always be the elimination of hazards, we will discuss the importance of safety training and communication.

Administrative Controls in the Oil and Gas Industry

Administrative controls include safeguards such as written safety policies, training, scheduling, and rules. While administrative controls are towards the bottom of the hierarchy, safety training and communication play a vital role in keeping employees safe. Safety training can encompass everything from a week-long site orientation training for new hires to five-minute safety talks prior to the start of a work shift.

Longer safety training is needed to ensure that employees understand the hazards of their work, possible negative outcomes, and how to mitigate hazards. Training should take place more than just once per year or at the time of hire. Ongoing safety meetings are a great way to communicate hazards and to provide training in shorter time spans.

Holding Safety Meetings

Safety talks, also called toolbox talks or safety meetings, are a great way to communicate relevant and timely information to the work crew. Dedicating time prior to work beginning not only demonstrates a company’s desire to work safely, but it is a great way to continue to educate workers on safety topics.

When frequent safety meetings are not held, it is easy for workers to get complacent. Even if the workers are not complacent, they may not be up to date on specific hazards, changing operations, or updated safety practices that are occurring on the worksite. The oil and gas industry is not stagnant, so safety training efforts should not be either.

This free website and the paid Members Area could be a great way to bolster your ongoing training efforts.

Using Our Resources for the Oil and Gas Industry

This website offers over 250 safety talks completely for free. You can view all of the free safety talks by clicking here. Additionally, a paid Members Area was created for those safety pros who are looking for more resources or different materials than what is offered on the free website. The oil and gas industry is one area that we had not previously covered before mid-2020. We have hired an oil and gas consultant to write safety talks to ensure this area was covered.

Currently, there are around 40 oil and gas safety talks available for members. Additional talks are being added monthly, with the goal of having at least 50 of these safety talk topics available for members. There is a multitude of topics found under the construction industry section of the Members Area that also apply to the oil and gas industry.

Members get access to ad-free PDF versions of all of the 250 free talks, an additional 300+ safety talk topics, pre-packaged safety meetings with PowerPoint presentations, 80 safety talks translated into Spanish, and weekly talk picks. There are more resources added every month.

The Complete List of Available Oil and Gas Topics for Members

- Centrifugal Pump Maintenance

- Chemical Hazards of Vessel Degassing

- Chemical Neutralization

- Chemical Transfer to Portable Containers

- Common Hazards When Working at Pipe Racks

- Coupon Testing

- Dangers of Improperly Grounding a Fuel Truck

- Five Hazards of Hot Fueling

- Four Hazards of Tripping Pipe

- Four Significant Hazards When Staging a Holding Tank

- High-Pressure Zone Safety

- Hydroblasting

- Noise Exposure in the Gas Industry

- Outrigger Deployment

- Respirator Care and Maintenance

- Safe Staging of a Mobile Crane

- Safely Boarding a Transfer Basket

- Significant Hazards of Well Center Entry

- Silica Exposure Hydraulic Fracturing Sand

- Tank Cleaning

- Three Common Injuries and Incidents When Installing Berms

- Three Hazards of Breaking Down Frac Piping

- Three Hazards of Inspecting Pressure Safety Valves

- Three Hazards of Lifting a Personnel Basket

- Three Hazards of Pipeline Installation

- Three Major Hazards of Cementing Wells

Do you want downloadable PDFs of all of the talks? Join as a member and get all of the 250+ free talks as well as 300+ additional talks in PDFs that are easy to download and print!

- Magazine Subscription

- ENewsletters

- EHS Education

- Safety Leadership Conference

- America's Safest Companies

- Search Search

- Members Only

- Environment

- Safety Technology

- Training & Engagement

Safety Practices in the Oil and Gas Industry (Infographic)

The oil and gas industry, potentially one of the most hazardous industry sectors in the United States, has one of the most thorough safety programs. The combination of powerful equipment, flammable chemicals and processes that are under high pressure can lead to hazardous and even deadly incidents. That’s why it’s essential for safety managers and supervisors to identify and communicate recommended safety controls and hazards that exist on each work site before work begins.

Graphic Products knows it’s essential for safety managers and supervisors to have the resources they need for optimal safety operations, so the company has released several visual communication resources specifically tailored for the oil and gas industry that include a safety best practices guide , quick safety tip articles , this informative infographic and more.

Sandy Smith

Sandy Smith is the former content director of EHS Today , and is currently the EHSQ content & community lead at Intelex Technologies Inc. She has written about occupational safety and health and environmental issues since 1990.

Continue Reading

Safety Tips for Oil and Gas Hazards

Fatal Four: Safety in the Construction Industry [Infographic]

Sponsored recommendations.

Free Webinar: ISO 45001 – A Commitment to Occupational Health, Safety & Personal Wellness

ISO 45003 – Psychological Health and Safety at Work

DH Pace, national door and dock provider, reduces TRIR and claims with EHS solution

Case Study: Improve TRIR from 4+ to 1 with EHS Solution and Safety Training

Voice your opinion, to join the conversation, and become an exclusive member of ehs today, create an account today.

SLC 2024 Preview: The 4 Keys to a World-Class Safety Culture

EPA Offers $850 Million For Oil, Gas Projects to Reduce Methane Emissions

Workplace Incivility, Climate Change Curriculum and Catan for Modern Times: What I’m Reading This Week

Battling Heat Stress: The Promise and Perils of Technology

6 Steps to Build Leadership Buy-In for EHS Technology

6 Qualities That Make a Safety Leader

Soft Skills 101: Three Essential Personal Attributes for Safety Professionals

News, knowledge and insights

Safety in oil and gas industry: common hazards & prevention.

Occupational safety is a key concern in any line of work, but especially so in high-risk industries such as the energy sector. Oil and gas workers face a host of potential dangers in their work environment, like falling equipment and hazardous chemicals.

With a higher possibility of being struck by hazards, workplace safety becomes all the more crucial — organisations should place the well-being of their workers at the heart of their culture and values.

In an interview with McKinsey & Company , Bernadette Spinoy — then senior vice president of health, safety, and environment (HSE) from the major global oil and gas player Total —talks about how inculcating a collective mindset in which workers choose the right behaviour even when no one is watching can lead to a successful safety culture transformation.

To encourage this collective behaviour, this article will cover 5 ways on how safety can be achieved in the oil and gas industry.

Safety Hazards and Risks in Oil and Gas Industry

According to the Occupational Safety and Health Administration (OSHA), these are just a few of the many workplace hazards that can occur in the oil and gas extraction industry.

Workers often must work from elevated platforms or equipment. This poses a risk of slips, trips, and falls that could cause serious bodily harm. Accessing these places via a ladder, would thus require more precautions to safely guide workers. Vigilance and proper safety training are essential.

2. Confined Spaces

Workers often must work within confined spaces, where there is a higher risk of health hazards such as asphyxiation or exposure to toxic chemicals. The ignition of flammable vapours or gases is also a possibility, in the event of small or narrow areas which would position workers directly in the danger zone.

3. Machine Hazards

Oil and gas extraction involves working with or around dangerous machinery. Workers could get struck by or caught between unguarded machines, which may result in cuts, burns, or other serious injuries. This is why routine checks and regular machine maintenance are important, as well as alertness to one’s surroundings in high-risk areas.

4. Explosions & Fires

The ignition of flammable gases or vapours can also result in explosions or fires, which can wreak damage on a large scale in such a hazardous environment. Some causes include electrical energy sources, open flames, and frictional heat. High-pressure lines may also leak or burst if not properly maintained.

5. Physical Strain

Oil and gas extraction is a physically demanding job that, even with the surplus of machines, often requires manual labour. Certain tasks, such as the lifting of heavy loads or equipment, can continuously exert a strain on workers’ bodies over time. Poor workplace ergonomics negatively affects safety in this area and can increase the risk of injury.

Tips to Prevent and Reduce Hazards in Oil and Gas Industry

While safety risks cannot be completely eliminated, they can be significantly reduced through awareness of potential hazards and how they can be avoided. Use these 5 safety tips to help improve worksite safety.

Tip #1 Establish Good Safety Culture

Workplace safety culture is a collective set of values and attitudes towards safety, which goes beyond the individual to the overall safety of the organisation. This sense of solidarity would encourage workers to obey rules and communicate hazards to keep themselves and their fellow workers safe.

A good safety culture begins with strong leadership, as workers would feel more reassured knowing that their well-being is being cared for from the top down. Aside from having processes that are tailored to your company, it is important that these are clearly stated and reinforced in the worksite

Not only does this ensure that safety precautions are observed, it will also give workers added peace of mind knowing the processes are in place for their occupational safety. Furthermore, the mental health of workers will go a long way in keeping them vigilant and alert on the job.

Tip #2 Learn to Embrace Automation & Digitalisation

While there are manual steps that can be taken to ensure overall safety, such as installing safety signs or having highly visible floor marking, we live in an age where technology can provide useful tools for detecting and minimising hazards.

SOL-X solutions provide valuable data and leading indicators through AI and IIoT. SOL-X is a management system focused on behavioural safety. By collating data on risk assessment and permits within the work environment, it provides real-time data to increase worker situational awareness, enhancing both safety and efficiency.

Through smart wearables and AI technology, SOL-X solution addresses human factors — the most common cause of workplace accidents such as inaccurate fatigue management. By tracking conditions such as heat stress levels, heart rate trends, and work rest hours, it also helps workers monitor their symptoms to ensure that they are physically fit for the tasks at hand.

Tip #3 Use the Process Safety Approach

The International Association of Oil & Gas Producers (IOGP) defines the Process Safety approach as the safe management of oil and gas operations and processes, with the aim of preventing hazardous emissions or structural failures that could lead to more severe consequences.

While the traditional approach to accident prevention is based on trial and error, Process Safety attempts to identify trends and so more accurately predict events based on probability. The implementation of relevant safety precautions can thus protect workers from situations that can be easily avoided.

According to the IOGP , there were 56 process safety events between 2007 and 2017 that led to 128 deaths. Combined with safety management systems like SOL-X and culture programmes, having process safety will greatly reduce the occurrence of oil and gas hazards.

Tip #4 Communicate with Emergency Response Organisations

Although prevention should always come first, unforeseen events may still occur from time to time. In such cases, a quick response could save a life. It is thus important for oil and gas companies to maintain good communication with their local emergency response community.

This includes emergency responders and health professionals who will be able to take action and help minimise the consequences in the event of an accident. Developing a collaborative relationship with these organisations can also be beneficial to the workers by increasing awareness of emergency and safety equipment.

Tip #5 Having Consistent Maintenance Activities & Safety Programmes

As with anything, consistency is key. Conducting regular maintenance checks and occupational safety training programmes can help to reinforce safety messages, especially for new workers entering a company. Since the job is highly focused on working with various equipment, routine maintenance is also mandatory to prevent premature machine failure.

Risks and hazards can look different from day to day, especially if a project begins that requires working with new materials or equipment. By encouraging consistent training, this also ensures that workers are prepared for any situation that may come their way.

Enhance Safety of Oil and Gas Workers with SOL-X Solutions

In such a high-risk environment, the safety of oil and gas workers should never be left to chance. The safety solutions provided by SOL-X can not only reduce hazards in the worksite, but also enable quicker responses and boost overall productivity.

Contact us to learn more about risk management and accident prevention today.

Get In Touch

First Name *

Last Name *

Company Email *

Company Name *

Product(s) of Interest * SOL-X PROPELLER ecoMax

I consent to Magellan X collecting and using my details in accordance with its Privacy Policy*

Related News

How SOL-X Improves Seafarer Mental Health and Well-being

Join Magellan X at the World Offshore Week 2023

Magellan X and Coolon Announce Strategic Partnership

SOL-X wins 2023 OH&S New Product of the Year

Sustainability in the Oil & Gas Industry: Why It Matters in 2023

EHS and Sustainability: Best Practices for Heavy Industries

Receive our latest updates.

- 65 Chulia St #48-03/04, OCBC Centre, Singapore 049513

- +65 6721 3023

- [email protected]

Quick Links

Schedule a demo.

- Terms of Use -

- Privacy Policy -

- Cookie Policy -

- Cookie Preferences

MAGELLAN X PTE. LTD. LEGAL NOTICE (TERMS AND CONDITIONS OF USE)

1. Use of the Magellan X Website

By accessing, browsing and using this website or downloading data, material, text, images, videos or audio etc. from the website, you accept without limitation or qualification these Terms and Conditions. Magellan X. Pte Ltd. (“Magellan X”) reserves all rights to amend or revised these Terms and Conditions and any services, data or information contained in or related to this website without prior notice. As such you are advised to regularly access these Terms and Conditions.

2. Copyright

All title, right and interest in trademarks, trade secrets, copyrights and other intellectual property rights of whatsoever nature in respect of or connected to this website shall vest and remain with Magellan X.

All trademarks, trade secrets, copyrights and other intellectual property shall be protected by the applicable laws and shall not be used in any way without the prior written permission of Magellan X.

3. Hyperlinked Website

You may come across independent websites, hyperlinked to Magellan X’s website (“Hyperlinked Website”). Kindly be informed that Magellan X has no control over the content of such Hyperlinked Website nor provides any warranty, representation or indemnity whatsoever in relation thereto. Magellan X shall not be deemed to endorse or accept responsibility of a hyperlink to or from a Hyperlinked Website.

4. Received Information

Information and data provided to Magellan X is furnished at the sender’s risk. Subject to the terms of any express undertaking or agreement, Magellan X makes no understanding to keep such information or data confidential to the extent permitted by applicable laws. Magellan X assumes no responsibility for loss or, unjustified access or alteration to, or transfer (whether or not erroneous or unjustified) to any third party, data or information provided to Magellan X.

5. Privacy Policy

Any personal data provided to Magellan X through this website will be used in accordance with Magellan X’s Privacy Policy. You may refer to Magellan X’s Privacy Policy here .

6. Exclusion of Liability

While Magellan X has made every attempt to ensure that the information contained in this website is accurate and up to date, Magellan X is not responsible or liable for any errors, inaccuracies or omissions, misuse or conversion of any data or information contained in, or derived from this website, or from the results obtained from the use of any data or information.

All information on this website is provided “as is” with no guarantee of completeness, accuracy, timelines or of results obtained from the use of this information and without warranty or representation of any kind, expressed or implied.

Magellan X provides no warranty, representation or indemnity that the use of material displayed on the website will not infringe the intellectual property rights of third parties.

Magellan X and/or its associated companies, directors, officers, employees, agents or representatives shall not be liable for any viruses or other malicious activities of whatsoever nature that may infect your computer, any other hardware, software or IT systems or other property on account of your accessing, browsing and/or using this website and any of its services or downloading of any material, data, text, images, video or audio from the website. Magellan X shall not be liable for any damages whatsoever due to a third party’s unjustified access to the website, passwords, data or information on the website.

Magellan X advises you to take the necessary measures to ensure that your computer, any hardware, software or other IT systems or other property are adequately protected from viruses or other malicious activities.

Magellan X and/or its associated companies, directors, officers, employees, agents or representatives shall not be liable for any decision made or action taken in reliance on the information on the website or for any loss, damage or claims of whatsoever nature (including but not limited to indirect and consequential loss) arising out of access to or use of this website, or its services, even if Magellan X is expressly advised of the possibility of any loss, damage or claims.

7. Law and Venue

This website, including these Terms and Conditions, shall be governed by the laws of Singapore and subject to the exclusive jurisdiction of the Courts of Singapore.

8. Unlawful Activities

Magellan X views seriously any unauthorised access (whether malicious or otherwise), alteration or modification of its website and/or the contents therein and will not hesitate to initiate and pursue appropriate legal action (civil or criminal) under the applicable laws.

If you have any questions or comments about the use of this website or your dealings with this website, you can contact: [email protected]

Last Updated: 29 June 2022

MAGELLAN X PTE. LTD. PRIVACY POLICY

Magellan X Pte. Ltd., its subsidiaries and affiliates (“ Magellan X ”, “ we ”, “ our ” and/or “ u s ”), are committed to safeguarding the Personal Information of our customers, vendors and users (“ User ” and/or “ you ”) who visit our website (“ Website” ). This privacy policy (“ Privacy Policy” ) sets out the ways in we collect your Personal Information, the purposes for which we use it and the instances where we share it with other individuals and organisations. “ Personal Information ” means any information relating to an identified or identifiable individual.

If you are an existing customer or vendor of ours, or a representative of an existing customer or vendor of ours, further details about how we use your Personal Information are set out in your/your employer’s customer/vendor contract with us. We may provide further notices to you at the point we collect your Personal Information, which will highlight any further information relating to our use of that Personal Information and, where applicable, provide you with the ability to opt in or out of selected uses.

This Privacy Policy is intended to explain our privacy practices and covers the following areas:

- What Personal Information about you we may collect;

- How we may use your Personal Information;

- How we protect your Personal Information;

- Contacting us and your rights to access and update your Personal Information; and

- How changes to this Privacy Policy and the Cookie Policy will be made.

This Privacy Policy applies to the activities for which Magellan X is a “data controller” which means that Magellan X decides why and how Personal Information is processed. Magellan X may also process User’s Personal Information as a “data processor” in the context of the services we provide to our customers. When we process Personal Information on behalf of our customers, customers determine “why” and “how” the Personal Information is processed. To learn more about the processing of your Personal Information in this context, please refer to their respective privacy policies.

If you are based in the European Economic Area (“ EEA ”) or the United Kingdom (“ UK ”) during your interactions with us (other than solely for travel purposes), the laws in those countries require us to provide you with additional information about our processing activities. We have included this information in the European Appendix .

1. Personal Information we may collect about you

We will collect and process all or some of the following Personal Information about you:

1.1 Personal Information you provide to us ► Personal Information that you provide to us, such as when using the contact form on our Website, including your name, email address, other contact details;

1.2 Personal Information you provide when applying for a role at Magellan X ► if you apply for a role at Magellan X through the Website, we may collect, where permitted by law and appropriate, your CV or résumé and contact details. We may also undertake criminal records or financial probity checks or other independent searches to assess your suitability for the position where permitted by, and in accordance with, applicable laws;

1.3 Our correspondence ► if you contact us, we will typically keep a record of that correspondence;

1.4 Your feedback ► we may ask you for feedback from time to time, that we use to help us to improve our service; and

1.5 Website and communication usage ► details of your visits to our Website and Personal Information collected through cookies and other tracking technologies including, but not limited to, your IP address and domain name, your browser version and operating system, information about your device, traffic data, location data, web logs and other communication data, and the resources that you access.

2. How We Use Your Personal Information

In this section, we set out the purposes for which we collect, process, store and use Personal Information described above:

2.1 To communicate effectively with you and conduct our business ► to conduct our business, including to respond to your queries, to otherwise communicate with you, or to carry out our obligations arising from any agreements entered into between you and us;

2.2 To assess your application for a role at Magellan X ► to assess your application prior to entering into an employment contract with us and pursuant to laws to which Magellan X is subject (e.g. in relation to equal opportunities). This processing is a necessary pre-condition of entering into any future contract with you and for Magellan X to fulfil its employment duties with respect to other employees and you (should you be employed by Magellan X). If you are unable to provide us with the Personal Information we request for this purpose, we may be unable to assess your appropriateness for the job applied for or to communicate with you.

2.3 To provide you with marketing materials ► to provide you with updates and offers, where you have chosen to receive these. We may also use your Personal Information for marketing our own products and services to you by post, email, and phone and, where required by law, we will ask for your consent at the time we collect your data to conduct any of these types of marketing. We will provide an option to unsubscribe or opt-out of further communication on any electronic marketing communication sent to you or you may opt out by contacting us as set out in the “Contacting Us” Section 4.2 below.

2.4 For research and development purposes ► to analyse your Personal Information in order to better understand your and our clients’ business and marketing requirements, to better understand our business and develop our products and services;

2.5 To monitor certain activities ► to monitor queries and transactions to ensure service quality, compliance with procedures and to combat fraud;

2.6 To inform you of changes ► to notify you about changes to our services and products;

2.7 To ensure website content is relevant ► to ensure that content from our websites is presented in the most effective manner for you and for your device, which may include passing your data to business partners, suppliers and/or service providers;

2.8 To re-organise or make changes to our business ► in the event that we: (i) are subject to negotiations for the sale of our business or part thereof to a third party; (ii) are sold to a third party; or (iii) undergo a re-organisation, we may need to transfer some or all of your Personal Information to the relevant third party (or its advisors) as part of any due diligence process for the purpose of analysing any proposed sale or re-organisation. We may also need to transfer your Personal Information to that re-organised entity or third party after the sale or reorganisation for them to use for the same purposes as set out in this Privacy Policy.

2.9 In connection with legal or regulatory obligations ► We may process your Personal Information to comply with our regulatory requirements or dialogue with regulators as applicable which may include disclosing your Personal Information to third parties, the court service and/or regulators or law enforcement agencies in connection with enquiries, proceedings or investigations by such parties anywhere in the world or where compelled to do so. Where permitted, we will generally direct any such request to you or notify you before responding unless to do so would prejudice the prevention or detection of a crime.

3. Transmission, storage and security of your Personal Information

3.1 Security over the Internet

No data transmission over the Internet or website can be guaranteed to be secure from intrusion. However, we maintain commercially reasonable physical, electronic and procedural safeguards to protect your Personal Information in accordance with applicable privacy and data protection laws.

All Personal Information you provide to us is stored on our or our subcontractors’ secure servers and accessed and used subject to applicable security policies and standards.

3.2 Sharing Your Personal Information

We may disclose Personal Information for the purposes we explain in this notice to service providers, contractors, agents, advisors (e.g. legal, financial, business or other advisors) that perform activities on our behalf and to other third parties in connection with our legal and regulatory obligations (as described above).

Our Website may contain links to other third-party websites. If you follow a link to any of those third-party websites, please note that they have their own privacy policies and that we do not accept any responsibility or liability for their policies or processing of your Personal Information. Please check these policies before you submit any Personal Information to such third-party websites.

3.3 Export to other countries

Your Personal Information may be accessed by staff or suppliers in, transferred to, and/or stored at, a destination outside the country in which you are located, whose data protection laws may be of a lower standard than those in your country. We will, in all circumstances, safeguard Personal Information as set out in this Privacy Policy.

3.4 Retention of Personal Information

Our retention periods for Personal Information are based on business needs and legal requirements. We retain Personal Information for as long as is necessary for the processing purpose(s) for which the Personal information was collected, and any other permissible, related purpose. For example, we may retain certain transaction details and correspondence until the time limit for claims arising from the transaction has expired, or to comply with regulatory requirements regarding the retention of such data. When Personal Information is no longer needed, we either irreversibly anonymise the data (and we may further retain and use the anonymised information) or securely destroy the data.

4. Your Rights and Contacting Us

4.1 Updating Personal information

We will use reasonable endeavours to ensure that your Personal Information is accurate. In order to assist us with this, you may notify us of any changes to the Personal Information that you have provided to us by contacting us as set out in the “Contacting Us” Section 4.2 below.

4.2 Contacting Us

If you have any questions in relation to this Privacy Policy, please contact our data protection officer at [email protected] or write to us at: 83 Clemenceau Avenue, #17-05/08, UE Square Singapore 239920.

4.3 Changes to our Privacy Policy

We may change the content of our Website and how we use your Personal Information from time to time. If we change this Privacy Policy, we will update the date it was last changed below. If these changes are material, we will indicate this clearly on our Website.

European Appendix

The European Appendix to this Privacy Policy applies if you are based in the EEA or the UK during your interactions with us (other than solely for travel purposes) and Magellan X processes your Personal Information as a data controller.

It sets out the additional information that we are required to provide you under European data protection law (“ EU DP Law” ), including information about rights that you have in relation to your Personal Information that we handle.

Why we collect your data, and who we disclose it to

Under EU DP Law, we are required to inform you of the “lawful bases” on which we rely to process your Personal Information. Below we set out the purposes for which we collect and use Personal Information and the “lawful bases” that we use for each of the purposes mentioned in Section 2 of this Privacy Policy. You can find an explanation of each of the grounds relied on below:

EU Use Bases Table

|

|

|

| ||

| 2.1 | – contract performance – legitimate interests (to enable us to perform our obligations and provide our services to you) |

| 2.2 | – contract performance – legal obligations – legitimate interests (to enable us to fulfil our employment duties with respect to other employees and you (should you be employed by Magellan X)) |

| 2.3 | – consent – legitimate interest (to keep you updated with news in relation to our products and services) |

| 2.4 | – legitimate interests (to allow us to improve our products and services) |

| 2.5 | – legal obligations – legal claims – legitimate interests (to ensure that the quality and legality of our services) |

| 2.6 | – legitimate interests (to notify you about changes to our products and services) |

| 2.7 | – legitimate interests (to allow us to provide you with the content and services on the websites) |

| 2.8 | – legitimate interests (in order to allow us to change our business) |

| 2.9 | – legal obligations – legal claims – legitimate interests (to defend, prosecute or make a claim against you, to cooperate with law enforcement and regulatory authorities) |

These are the principal legal grounds that justify our use of your Personal Information:

Consent : where you have consented to our use of your Personal Information (you will have been presented with consent language in relation to any such use), You have the right to withdraw any consent you previously provided to us regarding the processing of your Personal Information, at any time and free of charge. We will apply your preferences going forward and this will not affect the lawfulness of the processing before your consent withdrawal. You may withdraw your consent by contacting us as set out in Section 4.2 ( Contacting Us) of this Privacy Policy.

Contract performance : where your Personal Information is necessary to enter into or perform our contract with you.

Legal obligation : where we need to use your Personal Information to comply with our legal obligations.

Legitimate interests : where we or a third party have a legitimate interest in using your Personal Information. We only rely on our or a third party’s legitimate interests to process your Personal Information when these interests are not overridden by your rights and interests.

Legal claims : where your information is necessary for us to defend, prosecute or make a claim against you, us or a third party.

Where applicable, we indicate whether and why you must provide us with your Personal Information, as well as the consequences of failing to do so. If you do not provide Personal Information when requested, you may not be able to benefit from our service if that information is necessary to provide you with it or if we are legally required to collect it.

Export outside the EEA

Your Personal Information may be accessed by staff or suppliers in, transferred to, and/or stored at, a destination outside the country in which you are located, including Singapore, whose data protection laws may be of a lower standard than those in your country. We will, in all circumstances, safeguard Personal Information as set out in this Privacy Policy.

Where we transfer Personal Information from inside the EEA to outside the EEA, we may be required to take specific additional measures to safeguard the relevant Personal Information. Certain countries outside the EEA have been approved by the European Commission as providing essentially equivalent protections to EEA data protection laws and therefore no additional safeguards are required to export Personal Information to these jurisdictions (please see the full list here: https://ec.europa.eu/info/law/law-topic/data-protection/international-dimension-data-protection/adequacy-decisions_en ). In countries which have not had these approvals, we will establish legal grounds justifying such transfer, such as EU Commission-approved model contractual clauses, or other legal grounds permitted by applicable legal requirements.

Please contact us as set out in Section 4.2 (Contacting Us) of this Privacy Policy if you would like to see a copy of the specific safeguards applied to the export of your Personal Information.

Your Additional Rights

If you have any questions in relation to our use of your Personal Information, you should first contact us as Section 4.2 (Contacting Us) of this Privacy Policy. Under EU DP Law, you may have the following additional rights in relation to your personal information to those set out in this Privacy Policy. Under certain conditions, you may have the right to require us to:

- provide you with further details on the use we make of your information;

- provide you with a copy of information that you have provided to us;

- update any inaccuracies in the Personal Information we hold (please see Section 4.2 of this Privacy Policy);

- delete any Personal Information the we no longer have a lawful ground to use;

- where processing is based on consent, to withdraw your consent so that we stop that particular processing (please see Section 2.3 of this Privacy Policy in relation to marketing);

- to ask us to transmit the Personal Information you have provided to us and we still hold about you to a third party electronically;

- object to any processing based on the legitimate interests ground unless our reasons for undertaking that processing outweigh any prejudice to your data protection rights; and

- restrict how we use your Personal Information whilst a complaint is being investigated.

Your exercise of these rights is subject to certain exemptions to safeguard the public interest (e.g. the prevention or detection of crime) and our interests (e.g. the maintenance of legal privilege). If you exercise any of these rights, we will check your entitlement and respond in most cases within a month.

If you are not satisfied with our use of your Personal Information or our response to any exercise of these rights you have the right to lodge a complaint with a data protection regulator in your country of residence, place of work or where an incident took place.

Contacting Us

If you have queries about any part of this European Appendix, please contact us as set out in Section 4.2 (Contacting Us) of this Privacy Policy.

If after contacting us you do not feel that we have adequately addressed your concerns, you may contact the data protection regulator in your country (the EEA data protection regulators are listed here: https://edpb.europa.eu/about-edpb/about-edpb/members_en ).

MAGELLAN X PTE. LTD. COOKIE POLICY

1. Use of Cookies

By browsing or using the Magellan X Website (“Website”), you consent to our use of cookies to collect information on your Website usage data and improve your online experience when browsing or transacting using the Website.

A cookies is a small file placed on your computer’s hard drive that helps to analyse web traffic or let you know when you visit a particular site, and can include information about the way you use a website, your choice of internet browser, the type of device you are accessing from, and where you are in the world. In particular:

- Cookies allow web applications to tailor its operations to your needs, likes and dislikes by gathering and remembering information about your preferences, but a cookie does not give us access to your computer or any information about you, other than the data you choose to share with us.

- Traffic log cookies enable us to identify which pages are being used and help us to analyse data about webpage traffic to tailor services to your needs. The information is used for statistical analysis, and the data is removed from the system thereafter.

You can choose to accept or decline cookies in the course of browsing the Website. Most web browsers automatically accept cookies, but you can usually modify your browser settings to decline cookies if you prefer. However, this may prevent you from taking full advantage of the Website.

If you have any questions or comments about the Magellan X’s cookie policy, you can contact: [email protected]

- Renewable Energy

Material Handling and Logistics

Autonomous transportation, entertainment, government and defense.

- Maritime and Cargo Logistics

- Science and Research

All Solutions and Technologies

Sustainability and ethics, news and media, trade shows and events, resource library, diversity and inclusion.

- Oil and Gas Home

- Asset Integrity

- C-Nav Positioning Solutions

- Data Management

- Decommissioning Solutions

- Flow Assurance

- Grayloc® Products

- Conventional NDT

- IMRGE™ Integrated, Customizable IMR Solutions

- Integrity Management

- ROV Technology

- Pipeline Repair Connections (PCRS)

- Remote Services

- Remotely Operated Vehicles (ROVs)

- Rotator Technologies

- Special Periodic Surveys and UWILD

- Subsea Connection Systems

- Subsea Distribution Solutions

- Subsea Tieback

- Survey and Mapping

- Well Intervention

- Workover Control Systems (WOCS)

- Renewable Energy Solutions

- Mobile Robotics

- Forklift Systems

- Underride Systems

- Lifecycle Services

- Autonomous Transport Systems

- Entertainment Ride Systems

- Oceaneering Space Systems (OSS)

- Neutral Buoyancy Laboratory Facilities

- Human Space Flight Systems

- Robotics and Automation

- Government and Defense Home

- Marine Services Division

- Submarine and Ship Repair Support Services

- Submarine Rescue Solutions

- Maritime and Cargo Logistics Home

- Automated Guided Vehicles (AGVs)

- Data Management and Communication Solutions

- Inspection and NDT

- Oceaneering Technologies (OTECH)

- Pipeline Repair

- Rotary Valves

- ROV Tooling

- Space Systems (OSS)

- Submarine and Ship Repair

- Submarine Rescue Systems

- Subsea Pumping Technology

- USV Services

- HSE and Quality

- Mission, Vision, and Values

- Corporate Sustainability

- Reducing CO2 Emissions

- Social Impact

- Ethics and Compliance

- Active Patents

- Product to Patent Mapping

- Employee Access

- EthicsPoint

- Subscribe to Updates

- News Releases

- Press Releases

- Financial News

- Publications

- All News and Press

- All Events and Webinars

- Case Studies

- All Resources

Safety Moments

- Quality Moments

- Careers Home

- Career Search

- Information for Job Seekers

- Employee Spotlight

- Veteran Spotlight

- Women in Technology

- Diversity and Inclusion Home

- Recruiting Calendar

- Veterans Recruiting

- Careers Newsletter

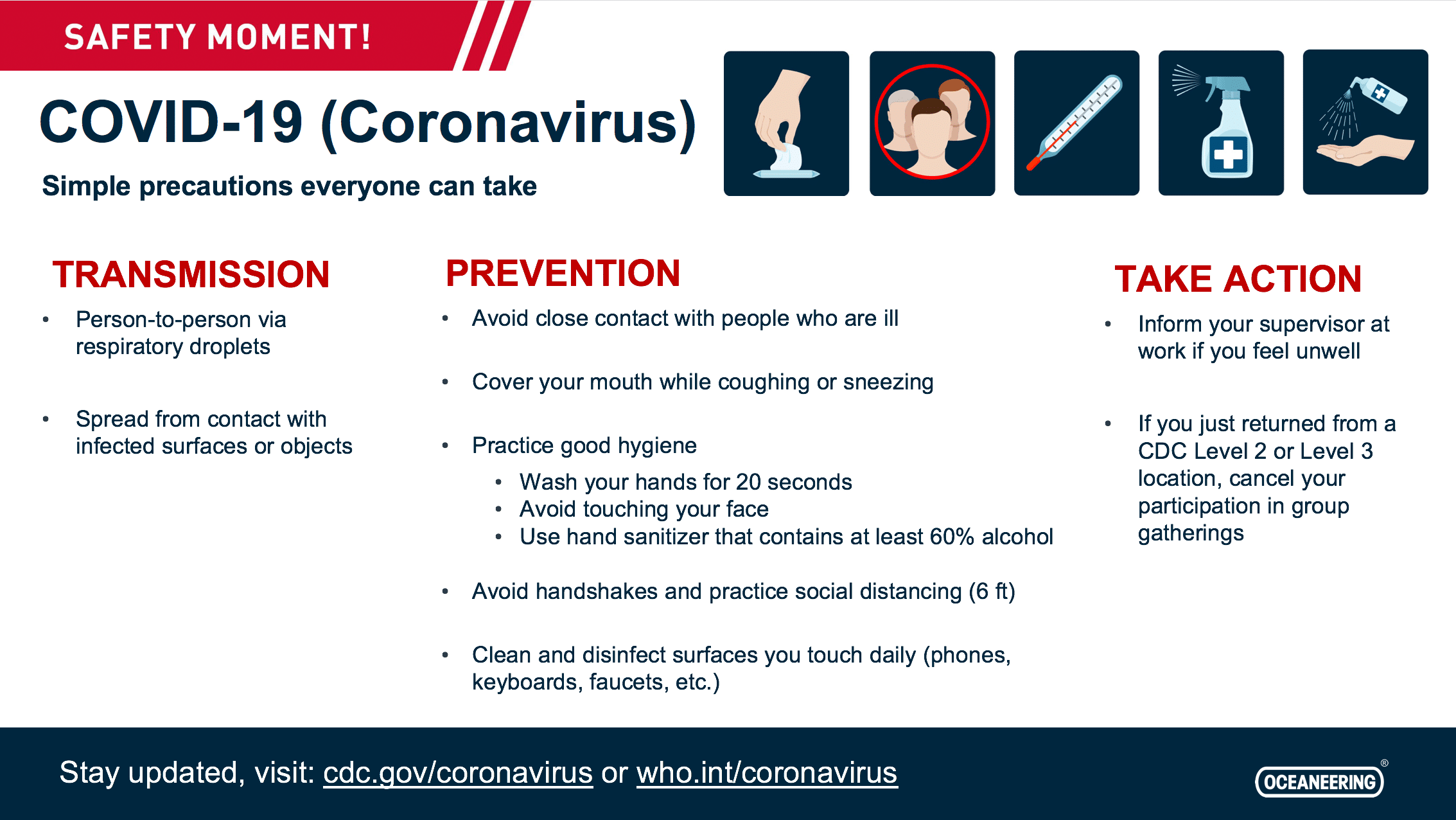

At Oceaneering, safety is our number one ethic and guides all that we do, from the wellsite to the board room. Our library of safety moment slides is available for meeting participants to address safety issues in a timely, clear and brief way at the start of any meeting.

Safety Moment of the Month

Download this month's slide to highlight safety in a timely and clear way at your next meeting.

All Safety Moments

Children’s Mental Health

What does your vehicle say about you?

Don’t fall for home falls

Healthy Vision

DVT/PE Risks and Flying

Dealing with Fatigue and Stress

Combatting Virtual Fatigue

Industrial Battery Systems Storage

Industrial Battery Systems Handling

Batteries at Home

Clean Workspace

Don’t Take Pain Sitting Down

Avoid Phishing Scams

Beat the Heat

COVID-19 Coronavirus Simple Precautions

Suspended Loads

Identity Theft

Stop the job

Lifting and Hoisting

Parking Lot Safety

Eye and Face Protection Safety

Pressurized Equipment Safety

Ladder Safety

Fire Prevention Tips

Know Before You Go

Distracted Walking

Office Safety

Taking Responsibility

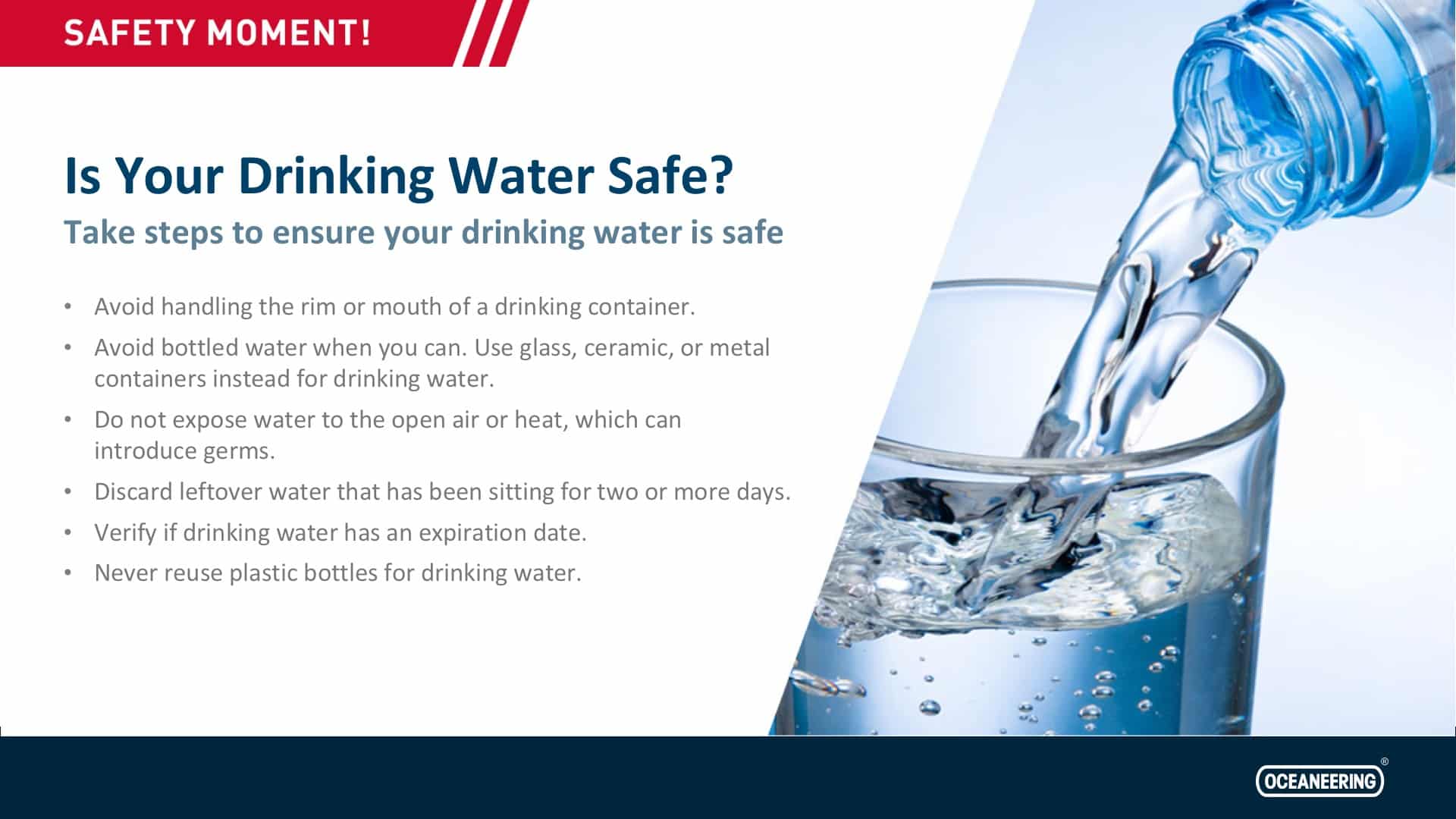

Is Your Drinking Water Safe?

Know Your Exits

Working at Height

Confined Space

Energy Isolation

Pressure Testing

Distracted Driving

The Lone Workers

Unsafe Acts and Conditions

Moments at the Sink, or Days Ill in Bed

Aerosol Can Safety

Do You Know What Tinnitus is?

Hand Tool Safety

Fire Safety

Happy With Your Work Space?

Slips Trips and Falls

Weather Preparedness

First Aid Saves Lives

Crane Safety

Our team of experts is ready to help you get started.

Oceaneering offers best-in-class products and solutions, backed by unparalleled quality, reliability, and global support. Fill out the inquiry form to start a conversation today.

Working to eliminate fatal and life changing injuries, and to increase resilience to major accident risks.

The Safety directorate’s Health, Safety, Security and Wells Expert committees work to eliminate fatal and life changing injuries, and to increase resilience to major accident risks. The combination of powerful equipment, flammable chemicals and processes that are under high pressure makes it the number one priority for the oil and gas industry, and it is becoming an ever more vital driver of operational value in a dynamic and fast paced business environment.

Well control

Directorate highlights.

Life-saving rules

Between 2008 and 2017, 376 people lost their lives in fatal incidents that might have been prevented by following one of iogp’s life-saving rules..

Process safety fundamentals

The IOGP Process Safety Fundamentals (PSFs) have been developed to support companies as they seek to reduce, and ultimately eliminate, fatal and high severity process safety events.

Start Work Checks

The Start Work Checks are recommended for companies who have launched, or are planning to launch, the Life-Saving Rules. The Checks enable frontline workers to confirm that the controls/safeguards designed to prevent fatalities and serious injuries are in place.

Effective guard force management – principles and guidelines (restricted to IOGP Members)

This Report provides advice and sets out the principles and guidelines to develop an effective guard force, as well as discussing administrative and contractual elements of guard force engagement.

Pandemic management in the oil and gas industry

This Report provides guidance for business continuity decision makers and medical personnel to plan effective responses to pandemic-scale infectious disease outbreaks, to aid organizations’ ability to operate, and to effectively contribute to societal responses. Specific oil and gas related risks and strategies are considered in the context of global, national, and local responses to pandemic infectious disease outbreaks.

Review of Well Control Incidents

This Info Sheet briefly summarizes the results of a review of 172 Well Control Incident reports submitted to IOGP by its Members through 2019. The objective of the review was to extract common findings, to identify areas to focus attention and to steer the Wells Expert Committee agenda, and to communicate and share the information with industry.

Latest News

Improving the communication of pore pressure fracture gradient (PPFG) interpretation and uncertainty

Uncertainties related to pore pressure and fracture gradient (PPFG) can play a significant role in causing well control incidents. The International Regulators Forum (IRF) has seen serious well control incidents relating to pore pressure and fracture gradient (PPFG) prediction and monitoring.

IOGP Report 642 – Learning from normal work now available in Portuguese

Now available in Portuguese, Learning from normal work, was first released in English in November 2022, and has been one of our most downloaded Reports over the past year.

Latest addition to IOGP’s Oil and Gas Aviation Recommended Practices (OGARP) series published

Fixed-wing commercial air transport recommended practices (IOGP Report 691) is the latest addition to IOGP’s Oil and Gas Aviation Recommended Practices (OGARP) series.

Partnership with the Energy Institute will further improve learning

To further improve learning from incidents and prevent repeat incidents, IOGP has partnered with the Energy Institute.

Study into the effectiveness of gamification techniques in workplace learning published

IOGP has published IOGP Report 668 – Gamification techniques in well control training and competency, a summary of a meta-analytical study into the effectiveness of gamification techniques in workplace learning.

Oxy-arc underwater cutting recommended practice published

IOGP has developed IOGP Report 471 – Oxy-arc underwater cutting recommended practice to assist with managing this activity and to provide control measures and guidance to ensure safe execution.

Motor vehicle crash data reports published

Driving-related incidents have historically been the largest cause of fatalities in IOGP Member Company operations.

Annual aviation safety performance data released

IOGP has released its annual aviation safety performance data report.

Enhancing Process Safety in Upstream Operations

Originally published in 2011 and now in its third edition, IOGP Report 456 – Process Safety – Recommended Practice on Key Performance Indicators (KPI) provides valuable guidance to upstream companies on the use of Key Performance Indicators to effectively manage process safety.

New edition of IOGP Report 476 – Recommendations for enhancements to well control training, examination and certification

IOGP’s Wells Expert Committee has released an updated version of IOGP Report 476 – Recommendations for enhancements to well control training, examination, and certification.

Shift from in-person to virtual training during pandemic resulted in low interaction between students and instructors

Using test results, simulator experiences, and a survey of over 500 students and instructors, IOGP studied the impact of virtual learning on well control competency

IOGP identifies potential causal factors in personal safety incidents

Insights from IOGP’s Safety Committee indicate lingering effects from the COVID-19 pandemic, increased industry activity, and geopolitical instability as potential causal factors for key safety indicators for our industry moving in the wrong direction.