Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Published: 27 April 2017

Technology: The Future of Agriculture

- Anthony King

Nature volume 544 , pages S21–S23 ( 2017 ) Cite this article

198k Accesses

218 Citations

227 Altmetric

Metrics details

- Agriculture

A technological revolution in farming led by advances in robotics and sensing technologies looks set to disrupt modern practice.

Over the centuries, as farmers have adopted more technology in their pursuit of greater yields, the belief that 'bigger is better' has come to dominate farming, rendering small-scale operations impractical. But advances in robotics and sensing technologies are threatening to disrupt today's agribusiness model. “There is the potential for intelligent robots to change the economic model of farming so that it becomes feasible to be a small producer again,” says robotics engineer George Kantor at Carnegie Mellon University in Pittsburgh, Pennsylvania.

Twenty-first century robotics and sensing technologies have the potential to solve problems as old as farming itself. “I believe, by moving to a robotic agricultural system, we can make crop production significantly more efficient and more sustainable,” says Simon Blackmore, an engineer at Harper Adams University in Newport, UK. In greenhouses devoted to fruit and vegetable production, engineers are exploring automation as a way to reduce costs and boost quality (see ‘ Ripe for the picking ’). Devices to monitor vegetable growth, as well as robotic pickers, are currently being tested. For livestock farmers, sensing technologies can help to manage the health and welfare of their animals (‘ Animal trackers ’). And work is underway to improve monitoring and maintenance of soil quality (‘ Silicon soil saviours ’), and to eliminate pests and disease without resorting to indiscriminate use of agrichemicals (‘ Eliminating enemies ’).

Although some of these technologies are already available, most are at the research stage in labs and spin-off companies. “Big-machinery manufacturers are not putting their money into manufacturing agricultural robots because it goes against their current business models,” says Blackmore. Researchers such as Blackmore and Kantor are part of a growing body of scientists with plans to revolutionize agricultural practice. If they succeed, they'll change how we produce food forever. “We can use technology to double food production,” says Richard Green, agricultural engineer at Harper Adams.

Ripe for the picking

The Netherlands is famed for the efficiency of its fruit- and vegetable-growing greenhouses, but these operations rely on people to pick the produce. “Humans are still better than robots, but there is a lot of effort going into automatic harvesting,” says Eldert van Henten, an agricultural engineer at Wageningen University in the Netherlands, who is working on a sweet-pepper harvester. The challenge is to quickly and precisely identify the pepper and avoid cutting the main stem of the plant. The key lies in fast, precise software. “We are performing deep learning with the machine so it can interpret all the data from a colour camera fast,” says van Henten. “We even feed data from regular street scenes into the neural network to better train it.”

In the United Kingdom, Green has developed a strawberry harvester that he says can pick the fruit faster than humans. It relies on stereoscopic vision with RGB cameras to capture depth, but it is its powerful algorithms that allow it to pick a strawberry every two seconds. People can pick 15 to 20 a minute, Green estimates. “Our partners at the National Physical Laboratory worked on the problem for two years, but had a brainstorm one day and finally cracked it,” says Green, adding that the solution is too commercially sensitive to share. He thinks that supervised groups of robots can step into the shoes of strawberry pickers in around five years. Harper Adams University is considering setting up a spin-off company to commercialize the technology. The big hurdle to commercialization, however, is that food producers demand robots that can pick all kinds of vegetables, says van Henten. The variety of shapes, sizes and colours of tomatoes, for instance, makes picking them a tough challenge, although there is already a robot available to remove unwanted leaves from the plants.

Another key place to look for efficiencies is timing. Picking too early is wasteful because you miss out on growth, but picking too late slashes weeks off the storage time. Precision-farming engineer Manuela Zude-Sasse at the Leibniz Institute for Agricultural Engineering and Bioeconomy in Potsdam, Germany, is attaching sensors to apples to detect their size, and levels of the pigments chlorophyll and anthocyanin. The data are fed into an algorithm to calculate developmental stage, and, when the time is ripe for picking, growers are alerted by smartphone.

So far, Zude-Sasse has put sensors on pears, citrus fruits, peaches, bananas and apples ( pictured ). She is set to start field trials later this year in a commercial tomato greenhouse and an apple orchard. She is also developing a smartphone app for cherry growers. The app will use photographs of cherries taken by growers to calculate growth rate and a quality score.

Growing fresh fruit and vegetables is all about keeping the quality high while minimizing costs. “If you can schedule harvest to optimum fruit development, then you can reap an economic benefit and a quality one,” says Zude-Sasse.

Eliminating enemies

The Food and Agriculture Organization of the United Nations estimates that 20–40% of global crop yields are lost each year to pests and diseases, despite the application of around two-million tonnes of pesticide. Intelligent devices, such as robots and drones, could allow farmers to slash agrichemical use by spotting crop enemies earlier to allow precise chemical application or pest removal, for example. “The market is demanding foods with less herbicide and pesticide, and with greater quality,” says Red Whittaker, a robotics engineer at Carnegie Mellon who designed and patented an automated guidance system for tractors in 1997. “That challenge can be met by robots.”

“We predict drones, mounted with RGB or multispectral cameras, will take off every morning before the farmer gets up, and identify where within the field there is a pest or a problem,” says Green. As well as visible light, these cameras would be able to collect data from the invisible parts of the electromagnetic spectrum that could allow farmers to pinpoint a fungal disease, for example, before it becomes established. Scientists from Carnegie Mellon have begun to test the theory in sorghum ( Sorghum bicolor ), a staple in many parts of Africa and a potential biofuel crop in the United States.

Agribotix, an agriculture data-analysis company in Boulder, Colorado, supplies drones and software that use near-infrared images to map patches of unhealthy vegetation in large fields. Images can also reveal potential causes, such as pests or problems with irrigation. The company processes drone data from crop fields in more than 50 countries. It is now using machine learning to train its systems to differentiate between crops and weeds, and hopes to have this capability ready for the 2017 growing season. “We will be able to ping growers with an alert saying you have weeds growing in your field, here and here,” says crop scientist Jason Barton, an executive at Agribotix.

Modern technology that can autonomously eliminate pests and target agrichemicals better will reduce collateral damage to wildlife, lower resistance and cut costs. “We are working with a pesticide company keen to apply from the air using a drone,” says Green. Rather than spraying a whole field, the pesticide could be delivered to the right spot in the quantity needed, he says. The potential reductions in pesticide use are impressive. According to researchers at the University of Sydney's Australian Centre for Field Robotics, targeted spraying of vegetables used 0.1% of the volume of herbicide used in conventional blanket spraying. Their prototype robot is called RIPPA (Robot for Intelligent Perception and Precision Application) and shoots weeds with a directed micro-dose of liquid. Scientists at Harper Adams are going even further, testing a robot that does away with chemicals altogether by blasting weeds close to crops with a laser. “Cameras identify the growing point of the weed and our laser, which is no more than a concentrated heat source, heats it up to 95 °C, so the weed either dies or goes dormant,” says Blackmore.

Animal trackers

Smart collars — a bit like the wearable devices designed to track human health and fitness — have been used to monitor cows in Scotland since 2010. Developed by Glasgow start-up Silent Herdsman, the collar monitors fertility by tracking activity — cows move around more when they are fertile — and uses this to alert farmers to when a cow is ready to mate, sending a message to his or her laptop or smartphone. The collars ( pictured ), which are now being developed by Israeli dairy-farm-technology company Afimilk after they acquired Silent Herdsman last year, also detect early signs of illness by monitoring the average time each cow spends eating and ruminating, and warning the farmer via a smartphone if either declines.

“We are now looking at more subtle behavioural changes and how they might be related to animal health, such as lameness or acidosis,” says Richard Dewhurst, an animal nutritionist at Scotland's Rural College (SRUC) in Edinburgh, who is involved in research to expand the capabilities of the collar. Scientists are developing algorithms to interrogate data collected by the collars.

In a separate project, Dewhurst is analysing levels of exhaled ketones and sulfides in cow breath to reveal underfeeding and tissue breakdown or excess protein in their diet. “We have used selected-ionflow-tube mass spectrometry, but there are commercial sensors available,” says Dewhurst.

Cameras are also improving the detection of threats to cow health. The inflammatory condition mastitis — often the result of a bacterial infection — is one of the biggest costs to the dairy industry, causing declines in milk production or even death. Thermal-imaging cameras installed in cow sheds can spot hot, inflamed udders, allowing animals to be treated early.

Carol-Anne Duthie, an animal scientist at SRUC, is using 3D cameras to film cattle at water troughs to estimate the carcass grade (an assessment of the quality of a culled cow) and animal weight. These criteria determine the price producers are paid. Knowing the optimum time to sell would maximize profit and provide abattoirs with more-consistent animals. “This has knock on effects in terms of overall efficiency of the entire supply chain, reducing the animals which are out of specification reaching the abattoir,” Duthie explains.

And researchers in Belgium have developed a camera system to monitor broiler chickens in sheds. Three cameras continually track the movements of thousands of individual birds to spot problems quickly. “Analysing the behaviour of broilers can give an early warning for over 90% of problems,” says bioengineer Daniel Berckmans at the University of Leuven. The behaviour-monitoring system is being sold by Fancom, a livestock-husbandry firm in Panningen, the Netherlands. The Leuven researchers have also launched a cough monitor to flag respiratory problems in pigs, through a spin-off company called SoundTalks. This can give a warning 12 days earlier than farmers or vets would normally be able to detect a problem, says Berckmans. The microphone, which is positioned above animals in their pen, identifies sick individuals so that treatment can be targeted. “The idea was to reduce the use of antibiotics,” says Berckmans.

Berckmans is now working on downsizing a stress monitor designed for people so that it will attach to a cow's ear tag. “The more you stress an animal, the less energy is available from food for growth,” he says. The monitor takes 200 physiological measurements a second, alerting farmers through a smartphone when there is a problem.

Silicon soil saviours

The richest resource for arable farmers is soil. But large harvesters damage and compact soil, and overuse of agrichemicals such as nitrogen fertilizer are bad for both the environment and a farmer's bottom line. Robotics and autonomous machines could help.

Data from drones are being used for smarter application of nitrogen fertilizer. “Healthy vegetation reflects more near-infrared light than unhealthy vegetation,” explains Barton. The ratio of red to near-infrared bands on a multispectral image can be used to estimate chlorophyll concentration and, therefore, to map biomass and see where interventions such as fertilization are needed after weather or pest damage, for example. When French agricultural technology company Airinov, which offers this type of drone survey, partnered with a French farming cooperative, they found that over a period of 3 years, in 627 fields of oilseed rape ( Brassica napus ), farmers used on average 34 kilograms less nitrogen fertilizer per hectare than they would without the survey data. This saved on average €107 (US$115) per hectare per year.

Bonirob ( pictured ) — a car-sized robot originally developed by a team of scientists including those at Osnabrück University of Applied Sciences in Germany — can measure other indicators of soil quality using various sensors and modules, including a moisture sensor and a penetrometer, which is used to assess soil compaction. According to Arno Ruckelshausen, an agricultural technologist at Osnabrück, Bonirob can take a sample of soil, liquidize it and analyse it to precisely map in real time characteristics such as pH and phosphorous levels. The University of Sydney's smaller RIPPA robot can also detect soil characteristics that affect crop production, by measuring soil conductivity.

Soil mapping opens the door to sowing different crop varieties in one field to better match shifting soil properties such as water availability. “You could differentially seed a field, for example, planting deep-rooting barley or wheat varieties in more sandy parts,” says Maurice Moloney, chief executive of the Global Institute for Food Security in Saskatoon, Canada. Growing multiple crops together could also lead to smarter use of agrichemicals. “Nature is strongly against monoculture, which is one reason we have to use massive amounts of herbicide and pesticides,” says van Henten. “It is about making the best use of resources.”

Mixed sowing would challenge an accepted pillar of agricultural wisdom: that economies of scale and the bulkiness of farm machinery mean vast fields of a single crop is the most-efficient way to farm, and the bigger the machine, the more-efficient the process. Some of the heaviest harvesters weigh 60 tonnes, cost more than a top-end sports car and leave a trail of soil compaction in their wake that can last for years.

But if there is no need for the farmer to drive the machine, then one large vehicle that covers as much area as possible is no longer needed. “As soon as you remove the human component, size is irrelevant,” says van Henten. Small, autonomous robots make mixed planting feasible and would not crush the soil.

In April, researchers at Harpers Adams began a proof-of-concept experiment with a hectare of barley. “We plan to grow and harvest the entire crop from start to finish with no humans entering the field,” says Green. The experiment will use existing machinery, such as tractors, that have been made autonomous, rather than new robots, but their goal is to use the software developed during this trial as the brains of purpose-built robots in the future. “Robots can facilitate a new way of doing agriculture,” says van Henten. Many of these disruptive technologies may not be ready for the prime time just yet, but the revolution is coming.

You can also search for this author in PubMed Google Scholar

Related links

Related links in nature research.

Bioengineering: Solar upgrade

Agrobiodiversity: The living library

Outlook on agriculture and drought

Related external links

Hands free hectare 2

Rights and permissions

Reprints and permissions

About this article

Cite this article.

King, A. Technology: The Future of Agriculture. Nature 544 , S21–S23 (2017). https://doi.org/10.1038/544S21a

Download citation

Published : 27 April 2017

Issue Date : 27 April 2017

DOI : https://doi.org/10.1038/544S21a

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

This article is cited by

Positive public attitudes towards agricultural robots.

- Hendrik Hilmar Zeddies

Scientific Reports (2024)

Enhancing Hill Farming Efficiency Using Unmanned Agricultural Vehicles: A Comprehensive Review

- Mrutyunjay Padhiary

- Laxmi Narayan Sethi

- Avinash Kumar

Transactions of the Indian National Academy of Engineering (2024)

How to make sense of 3D representations for plant phenotyping: a compendium of processing and analysis techniques

- Negin Harandi

- Breght Vandenberghe

- Arnout Van Messem

Plant Methods (2023)

Precise in-field molecular diagnostics of crop diseases by smartphone-based mutation-resolved pathogenic RNA analysis

- Qingdong Zeng

- Ruijie Deng

Nature Communications (2023)

Nachhaltige Digitalisierung. Gesellschaftliche Transformation, autonome Materialität und der Fall des Digital Farming

- Anna Henkel

Berliner Journal für Soziologie (2023)

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

Sign up for the Nature Briefing: Anthropocene newsletter — what matters in anthropocene research, free to your inbox weekly.

Information

- Author Services

Initiatives

You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

All articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer to https://www.mdpi.com/openaccess .

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

Original Submission Date Received: .

- Active Journals

- Find a Journal

- Proceedings Series

- For Authors

- For Reviewers

- For Editors

- For Librarians

- For Publishers

- For Societies

- For Conference Organizers

- Open Access Policy

- Institutional Open Access Program

- Special Issues Guidelines

- Editorial Process

- Research and Publication Ethics

- Article Processing Charges

- Testimonials

- Preprints.org

- SciProfiles

- Encyclopedia

Article Menu

- Subscribe SciFeed

- Recommended Articles

- PubMed/Medline

- Google Scholar

- on Google Scholar

- Table of Contents

Find support for a specific problem in the support section of our website.

Please let us know what you think of our products and services.

Visit our dedicated information section to learn more about MDPI.

JSmol Viewer

Research progress of hydrogen production technology and related catalysts by electrolysis of water, 1. introduction, 2. brief introduction of hydrogen production technologies, 2.1. alkaline water electrolysis hydrogen production.

Click here to enlarge figure

2.1.1. Transition Metal and Alloy Catalysts

2.1.2. transition metal oxide catalyst, 2.1.3. transition metal sulfide catalyst, 2.1.4. transition metal phosphide catalyst, 2.2. proton exchange membrane water electrolysis hydrogen production, 2.3. solid oxide water electrolysis hydrogen production, 3. conclusions, author contributions, conflicts of interest.

- Muradov, N.Z.; Veziroğlu, T.N. “Green” path from fossil-based to hydrogen economy: An overview of carbon-neutral technologies. Int. J. Hydrogen Energy 2008 , 33 , 6804–6839. [ Google Scholar ] [ CrossRef ]

- Chen, X.; Lin, B. Towards carbon neutrality by implementing carbon emissions trading scheme: Policy evaluation in China. Energy Policy 2021 , 157 , 112510. [ Google Scholar ] [ CrossRef ]

- Hou, Z.M.; Xiong, Y.; Luo, J.S.; Fang, Y.L.; Haris, M.; Chen, Q.J.; Yue, Y.; Wu, L.; Wang, Q.C.; Huang, L.C.; et al. International experience of carbon neutrality and prospects of key technologies: Lessons for China. Pet. Sci. 2023 , 20 , 893–909. [ Google Scholar ] [ CrossRef ]

- Taherian, Z.; Khataee, A.; Han, N.; Orooji, Y. Hydrogen production through methane reforming processes using promoted-Ni/mesoporous silica: A review. J. Ind. Eng. Chem. 2022 , 107 , 20–30. [ Google Scholar ] [ CrossRef ]

- Gao, Y.; Jiang, J.; Meng, Y.; Yan, F.; Aihemaiti, A. A review of recent developments in hydrogen production via biogas dry reforming. Energy Convers. Manag. 2018 , 171 , 133–155. [ Google Scholar ] [ CrossRef ]

- Kumar, G.; Mathimani, T.; Rene, E.R.; Pugazhendhi, A. Application of nanotechnology in dark fermentation for enhanced biohydrogen production using inorganic nanoparticles. Int. J. Hydrogen Energy 2019 , 44 , 13106–13113. [ Google Scholar ] [ CrossRef ]

- Jayachandran, V.; Basak, N.; De Philippis, R.; Adessi, A. Novel strategies towards efficient molecular biohydrogen production by dark fermentative mechanism: Present progress and future perspective. Bioprocess. Biosyst. Eng. 2022 , 45 , 1595–1624. [ Google Scholar ] [ CrossRef ]

- Wang, S.; Lu, A.; Zhong, C.J. Hydrogen production from water electrolysis: Role of catalysts. Nano Converg. 2021 , 8 , 1–23. [ Google Scholar ] [ CrossRef ]

- Ahmed, S.F.; Mofijur, M.; Nuzhat, S.; Rafa, N.; Musharrat, A.; Lam, S.S.; Boretti, A. Sustainable hydrogen production: Technological advancements and economic analysis. Int. J. Hydrogen Energy 2022 , 47 , 37227–37255. [ Google Scholar ] [ CrossRef ]

- Zhang, B.; Zhang, S.X.; Yao, R.; Wu, Y.H.; Qiu, J.S. Progress and prospects of hydrogen production: Opportunities and challenges. J. Electron. Sci. Technol. 2021 , 19 , 100080. [ Google Scholar ] [ CrossRef ]

- Tahir, M.; Pan, L.; Idrees, F.; Zhang, X.; Wang, L.; Zou, J.-J.; Wang, Z.L. Electrocatalytic oxygen evolution reaction for energy conversion and storage: A comprehensive review. Nano Energy 2017 , 37 , 136–157. [ Google Scholar ] [ CrossRef ]

- Peng, J.; Tao, P.; Song, C.; Shang, W.; Deng, T.; Wu, J. Structural evolution of Pt-based oxygen reduction reaction electrocatalysts. Chin. J. Catal. 2022 , 43 , 47–58. [ Google Scholar ] [ CrossRef ]

- Yang, W.; Zhang, W.; Liu, R.; Lv, F.; Chao, Y.; Wang, Z.; Guo, S. Amorphous Ru nanoclusters onto Co-doped 1D carbon nanocages enables efficient hydrogen evolution catalysis. Chin. J. Catal. 2022 , 43 , 110–115. [ Google Scholar ] [ CrossRef ]

- Liu, Y.; Liang, X.; Chen, H.; Gao, R.; Shi, L.; Yang, L.; Zou, X. Iridium-containing water-oxidation catalysts in acidic electrolyte. Chin. J. Catal. 2021 , 42 , 1054–1077. [ Google Scholar ] [ CrossRef ]

- Anantharaj, S.; Ede, S.R.; Sakthikumar, K.; Karthick, K.; Mishra, S.; Kundu, S. Recent trends and perspectives in electrochemical water splitting with an emphasis on sulfide, selenide, and phosphide catalysts of Fe, Co, and Ni: A review. ACS Catal. 2016 , 6 , 8069–8097. [ Google Scholar ] [ CrossRef ]

- Anantharaj, S.; Kundu, S.; Noda, S. Progress in nickel chalcogenide electrocatalyzed hydrogen evolution reaction. J. Mater. Chem. A 2020 , 8 , 4174–4192. [ Google Scholar ] [ CrossRef ]

- Yin, J.; Jin, J.; Lin, H.; Yin, Z.; Li, J.; Lu, M.; Guo, L.; Xi, P.; Tang, Y.; Yan, C.-H. Optimized metal chalcogenides for boosting water splitting. Adv. Sci. 2020 , 7 , 1903070. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Peng, L.; Shoaib, S.; Shah, A.; Wei, Z. Recent developments in metal phosphide and sulfide electrocatalysts for oxygen evolution reaction. Chin. J. Catal. 2018 , 39 , 1575–1593. [ Google Scholar ] [ CrossRef ]

- Lv, Z.; Mahmood, N.; Tahir, M.; Pan, L.; Zhang, X.; Zou, J.-J. Fabrication of zero to three dimensional nanostructured molybdenum sulfides and their electrochemical and photocatalytic applications. Nanoscale 2016 , 8 , 18250–18269. [ Google Scholar ] [ CrossRef ]

- Li, Y.; Nakamura, R. Structural change of molybdenum sulfide facilitates the electrocatalytic hydrogen evolution reaction at neutral pH as revealed by in situ Raman spectroscopy. Chin. J. Catal. 2018 , 39 , 401–406. [ Google Scholar ] [ CrossRef ]

- Brauns, J.; Turek, T. Alkaline water electrolysis powered by renewable energy: A review. Processes 2020 , 8 , 248. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Zeng, K.; Zhang, D.K. Recent progress in alkaline water electrolysis for hydrogen production and application. Prog. Energy Combust. Sci. 2010 , 36 , 307–326. [ Google Scholar ] [ CrossRef ]

- Falcão, D.S.; Pinto, A. A review on PEM electrolyzer modelling: Guidelines for beginners. J. Clean. Prod. 2020 , 261 , 121184. [ Google Scholar ] [ CrossRef ]

- Reza, A.; Brian, P.; Lin, S.; Wang, J.; Zhao, Y.; Xu, H.; Pivovar, B.; Tian, B.; Chen, X. A roadmap to low-cost hydrogen with hydroxide exchange membrane electrolyzers. Adv. Mater. 2019 , 31 , 1805876. [ Google Scholar ]

- Anwar, S.; Khan, F.; Zhang, Y.H.; Djire, A. Recent development in electrocatalysts for hydrogen production through water electrolysis. Int. J. Hydrogen Energy 2021 , 46 , 32284–32317. [ Google Scholar ] [ CrossRef ]

- Ursua, A.; Gandia, L.M.; Sanchis, P. Hydrogen production from water electrolysis: Current status and future trends. Proc. IEEE 2012 , 100 , 410–426. [ Google Scholar ] [ CrossRef ]

- Li, Z.; Hu, M.; Wang, P.; Liu, J.; Yao, J.; Li, C. Heterojunction catalyst in electrocatalytic water splitting. Coord. Chem. Rev. 2021 , 439 , 213953. [ Google Scholar ] [ CrossRef ]

- Yang, E.; Mohamed, H.O.; Park, S.G.; Obaid, M.; Al-Qaradawi, S.Y.; Castaño, P.; Chon, K.; Chae, K.J. A review on self-sustainable microbial electrolysis cells for electro-biohydrogen production via coupling with carbon-neutral renewable energy technologies. Bioresour. Technol. 2021 , 320 , 124363. [ Google Scholar ] [ CrossRef ]

- Khatib, F.N.; Wilberforce, T.; Ijaodol, O.; Ogungbemi, E.; El-Hassana, Z.; Durranta, A.; Thompsona, J.; Olabi, A. Material degradation of components in polymer electrolyte membrane (PEM) electrolytic cell and mitigation mechanisms: A review. Renew. Sustain. Energy Rev. 2019 , 111 , 1–14. [ Google Scholar ] [ CrossRef ]

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen production for energy: An overview. Int. J. Hydrogen Energy 2020 , 45 , 3847–3869. [ Google Scholar ] [ CrossRef ]

- Park, J.E.; Kang, S.Y.; Oh, S.H. High-performance anion exchange membrane water electrolysis. Electrochim. Acta 2019 , 295 , 99–106. [ Google Scholar ] [ CrossRef ]

- Vincent, I.; Kruger, A.; Bessarabov, D. Hydrogen production by water electrolysis with an ultrathin anion-exchange membrane(AEM). Int. J. Electrochem. Sci. 2018 , 13 , 11347–11358. [ Google Scholar ] [ CrossRef ]

- Chen, P.J.; Hu, X.L. High-efficiency anion exchange membrane water electrolysis employing non-noble metal catalysts. Adv. Energy Mater. 2020 , 10 , 2002285. [ Google Scholar ] [ CrossRef ]

- Chatenet, M.; Pollet, B.G.; Dekel, D.R. Water electrolysis: From textbook knowledge to the latest scientific strategies and industrial developments. Chem. Soc. Rev. 2022 , 51 , 4583–4762. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Liu, T.; Li, M.; Bo, X.; Zhou, M. Designing transition metal alloy nanoparticles embedded hierarchically porous carbon nanosheets as high-efficiency electrocatalysts toward full water splitting. J. Colloid Interface Sci. 2019 , 537 , 280–294. [ Google Scholar ] [ CrossRef ]

- Dong, S.; Li, Y.; Zhao, Z.; Hu, X.; Li, R.; Sun, S.; Zhang, X. Reparation of porous Ti-Cu alloy by one-step sintering method and application of hydrogen evolution reaction. J. Electroanal. Chem. 2022 , 918 , 116448. [ Google Scholar ] [ CrossRef ]

- Yang, L.; Zhou, H.; Qin, X.; Guo, X.; Cui, G.; Asiri, A.M.; Sun, X. Cathodic electrochemical activation of Co 3 O 4 nanoarrays: A smart strategy to significantly boost the hydrogen evolution activity. Chem. Commun. 2018 , 54 , 2150–2153. [ Google Scholar ] [ CrossRef ]

- Begum, H.; Ahmed, M.S.; Jeon, S.; Jeon, S. δ-MnO 2 nanoflowers on sulfonated graphene sheets for stable oxygen reduction and hydrogen evolution reaction. Electrochim. Acta 2019 , 296 , 235–242. [ Google Scholar ] [ CrossRef ]

- Wang, Y.; Liu, J.C.; Liao, Y.F. Hetero-structured V-Ni 3 S 2 @NiOOH core-shell nanorods from an electrochemical anodization for water splitting. J. Alloys Compd. 2021 , 856 , 158219. [ Google Scholar ] [ CrossRef ]

- Ha, Y.; Shi, L.X.; Yan, X.X.; Chen, Z.L.; Li, Y.P.; Xu, W.; Wu, R.B. Multifunctional Electrocatalysis on a Porous N-doped NiCo 2 O 4 @C Nanonetwork. ACS Appl. Mater. Interfaces 2019 , 11 , 45546–45553. [ Google Scholar ] [ CrossRef ]

- Köse, K.Ö.; Aydınol, M.K. Development of activated carbon/bimetallic transition metal phosphide composite materials for electrochemical capacitors and oxygen evolution reaction catalysis. Int. J. Energy Res. 2022 , 46 , 22078–22088. [ Google Scholar ] [ CrossRef ]

- Wang, L.; Gong, N.; Zhou, Z.; Peng, W.; Li, Y.; Zhang, F.; Fan, X. Electronic modulation of multi-element transition metal phosphide by V-doping for high-efficiency and pH-universal hydrogen evolution reaction. Int. J. Hydrogen Energy 2022 , 47 , 18305–18313. [ Google Scholar ] [ CrossRef ]

- Kibsgaard, J.; Tsai, C.; Chan, K.; Benck, J.D.; Nørskov, J.K.; Pedersen, F.A.; Jaramillo, T.F. Designing an improved transition metal phosphide catalyst for hydrogen evolution using experimental and theoretical trends. Energy Environ. Sci. 2015 , 8 , 3022–3029. [ Google Scholar ] [ CrossRef ]

- Bodner, M.; Hofer, A.; Hacker, V. H 2 generation from alkaline electrolyzer. Wiley Energy Environ. 2015 , 4 , 365–381. [ Google Scholar ] [ CrossRef ]

- Rosalbino, F.; Macciò, D.; Angelini, E.; Saccone, A.; Delfino, D. Electrocatalytic properties of Fe-R (R = rare earth metal) crystalline alloys as hydrogen electrodes in alkaline water electrolysis. J. Alloys Compd. 2005 , 403 , 275–282. [ Google Scholar ] [ CrossRef ]

- Rosalbino, F.; Macciò, D.; Angelini, E.; Saccone, A.; Delfino, S. Characterization of Fe-Zn-R (R = rare earth metal) crystalline alloys as electrocatalysts for hydrogen evolution. J. Hydrogen Energy 2008 , 33 , 2660–2667. [ Google Scholar ] [ CrossRef ]

- Li, Z.; Lv, L.; Ao, X.; Li, A.; Sun, H.; An, P.; Xue, X.; Li, Y.; Liu, M.; Wang, C.; et al. An effective method for enhancing oxygen evolution kinetics of LaMO 3 (M = Ni, Co, Mn) perovskite catalysts and its application to a rechargeable zinc–air battery. Appl. Catal. B Environ. 2020 , 262 , 118291. [ Google Scholar ] [ CrossRef ]

- Matsumoto, Y.; Manade, H.; Sato, E. Oxygen Evolution on La 1–x Sr x CoO 3 Electrodes in Alkaline Solutions. J. Electrochem. Soc. 1980 , 4 , 811–817. [ Google Scholar ] [ CrossRef ]

- Mizusaki, J.; Mima, Y.; Yamauchis, S.; Fueki, K.; Tagawa, H. Nonstoichiometry of the perovskite-type oxides La 1−x Sr x CoO 3−δ . J. Solid State Chem. 1989 , 80 , 102–111. [ Google Scholar ] [ CrossRef ]

- Svegl, F.; Orel, B.; Svegl, I.G.; Kaucic, V. Characterization of spinel Co 3 O 4 and Li-doped Co 3 O 4 thin film electrocatalysts prepared by the Sol-Gel route. J. Electrochim. Acta 2000 , 45 , 4359–4371. [ Google Scholar ] [ CrossRef ]

- Gao, X.; Zhang, H.; Li, Q.; Yu, X.; Hong, Z.; Zhang, X.; Liang, C.; Lin, Z. Hierarchical NiCo 2 O 4 hollow microcuboids as bifunctional electrocatalysts for overall water-splitting. Angew. Chem. Int. Ed. 2016 , 55 , 6290–6294. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Lankhost, M.H.R.; Bouwmeester, H.J.M.; Verweij, H. Importance of electronic band structure to nonstoichiometric behaviour of La 0.8 Sr 0.2 CoO 3 . Solid State Ion. 1997 , 96 , 21–27. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Otagawa, T.; Bockris, J.O.M. Lanthanum Nickelate as Electrocatalyst Oxygen Evolution. J. Electrochem. Soc. 1982 , 10 , 2391–2392. [ Google Scholar ] [ CrossRef ]

- Rogachev, A.S.; Fourmont, A.; Kovalev, D.Y.; Vadchenko, S.G.; Kochetov, N.A.; Shkodich, N.F.; Baras, F.; Politano, O. Mechanical alloying in the Co-Fe-Ni powder mixture: Experimental study and molecular dynamics simulation. Powder Technol. 2022 , 399 , 117187. [ Google Scholar ] [ CrossRef ]

- Atanova, A.V.; Seregin, D.S.; Zhigalina, O.M.; Khmelenin, D.N.; Orlov, G.A.; Turkina, D.I.; Sigov, A.S.; Vorotilov, K.A. Control of Columnar Grain Microstructure in CSD LaNiO 3 Films. Molecules 2023 , 28 , 1938. [ Google Scholar ] [ CrossRef ]

- Chang, H.; Liang, Z.; Wang, L.; Wang, C. Research progress in improving the oxygen evolution reaction by adjusting the 3d electronic structure of transition metal catalysts. Nanoscale 2022 , 14 , 5639–5656. [ Google Scholar ] [ CrossRef ]

- Wang, M.; Zhang, L.; He, Y.; Zhu, H. Recent advances in transition-metal-sulfide-based bifunctional electrocatalysts for overall water splitting. J. Mater. Chem. A 2021 , 9 , 5320–5363. [ Google Scholar ] [ CrossRef ]

- Wang, J.; Zhang, Z.; Song, H.; Zhang, B.; Liu, J.; Shai, X.; Miao, L. Water dissociation kinetic-oriented design of nickel sulfides via tailored dual sites for efficient alkaline hydrogen evolution. Adv. Funct. Mater. 2020 , 31 , 2008578. [ Google Scholar ] [ CrossRef ]

- Fei, B.; Chen, Z.; Liu, J.; Xu, H.; Yan, X.; Qing, H.; Chen, M.; Wu, R. Ultrathinning nickel sulfide with modulated electron density for efficient water splitting. Adv. Energy Mater. 2020 , 10 , 2001963. [ Google Scholar ] [ CrossRef ]

- Joo, J.; Kim, T.; Lee, J.; Choi, A.I.; Lee, K.Y. Morphology-controlled metal sulfides and phosphides for electrochemical water splitting. Adv. Mater. 2019 , 31 , 1806682. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Pei, Y.; Cheng, Y.; Chen, J.; Smith, W.; Dong, P.; Ajayan, P.M.; Ye, M.; Shen, J. Recent developments of transition metal phosphides as catalysts in the energy conversion field. J. Mater. Chem. A 2018 , 6 , 23220–23243. [ Google Scholar ] [ CrossRef ]

- Li, Y.; Li, R.; Wang, D.; Xu, H.; Meng, F.; Dong, D.; Jiang, J.; Zhang, J.; An, M.; Yang, P. A review: Target-oriented transition metal phosphide design and synthesis for water splitting. Int. J. Hydrogen Energy 2021 , 46 , 5131–5149. [ Google Scholar ] [ CrossRef ]

- Shi, Y.; Zhang, B. Recent advances in transition metal phosphide nanomaterials: Synthesis and applications in hydrogen evolution reaction. Chem. Soc. Rev. 2016 , 45 , 1529–1541. [ Google Scholar ] [ CrossRef ]

- Su, W.; Wang, D.; Zhou, Q.; Zheng, X. Preparation of 3D Fe-Co-Ni-OH/NiCoP electrode as a highly efficient electrocatalyst in the oxygen evolution reactions. J. Alloys Compd. 2023 , 941 , 168578. [ Google Scholar ] [ CrossRef ]

- Xu, H.; Zhu, J.; Wang, P.; Chen, D.; Zhang, C.; Xiao, M.; Ma, Q.; Bai, H.; Qin, R.; Ma, J.; et al. Fe–Co–P multi-heterostructure arrays for efficient electrocatalytic water splitting. J. Mater. Chem. A 2021 , 9 , 24677–24685. [ Google Scholar ] [ CrossRef ]

- Barbir, F. PEM electrolysis for production of hydrogen from renewable energy sources. Sol. Energy 2005 , 78 , 661–669. [ Google Scholar ] [ CrossRef ]

- Carmo, M.; Fritz, D.L.; Merge, J.; Stolten, D. A comprehensive review on PEM water electrolysis. Int. J. Hydrogen Energy 2013 , 38 , 4901–4934. [ Google Scholar ] [ CrossRef ]

- Bühler, M.; Holzapfel, P.; McLaughlin, D.; Thiele, S. From catalyst coated membranes to porous transport electrode based configurations in PEM water electrolyzers. J. Electrochem. Soc. 2019 , 166 , F1070. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Kumar, S.S.; Himabindu, V. Hydrogen production by PEM water electrolysis—A review. Mat. Sci. Energy Technol. 2019 , 2 , 442–454. [ Google Scholar ]

- Zhang, S.; Ma, X.; He, Y.; Zhu, Y.; Wang, Z. Amorphous mixed Ir-Mn oxide catalysts for the oxygen evolution reaction in PEM water electrolysis for H 2 production. Int. J. Hydrogen Energy 2023 , 48 , 10532–10544. [ Google Scholar ] [ CrossRef ]

- Han, S.-B.; Mo, Y.-H.; Lee, Y.-S.; Lee, S.-G.; Park, D.-H.; Park, K.-W. Mesoporous iridium oxide/Sb-doped SnO 2 nanostructured electrodes for polymer electrolyte membrane water electrolysis. Int. J. Hydrogen Energy 2020 , 45 , 1409–1416. [ Google Scholar ] [ CrossRef ]

- Morozan, A.; Johnson, H.; Roiron, C.; Genay, G.; Aldakov, D.; Ghedjatti, A.; Nguyen, C.T.; Tran, P.D.; Kinge, S.; Artero, V. Nonprecious Bimetallic Iron−Molybdenum Sulfide Electrocatalysts for the Hydrogen Evolution Reaction in Proton Exchange Membrane Electrolyzers. ACS Catal. 2020 , 10 , 14336–14348. [ Google Scholar ] [ CrossRef ]

- Giovanni, C.D.; Reyes-Carmona, Á.; Coursier, A.; Nowak, S.; Greneche, J.-M.; Lecoq, H.; Mouton, L.; Roziere, J.; Jones, D.; Peron, J.; et al. Low-Cost Nanostructured Iron Sulfide Electrocatalysts for PEM Water Electrolysis. ACS Catal. 2016 , 6 , 2626–2631. [ Google Scholar ] [ CrossRef ]

- Kim, H.; Park, H.; Kim, D.-K.; Choi, I.; Kim, S.-K. Pulse-electrodeposited nickel phosphide for high-performance proton exchange membrane water electrolysis. J. Alloys Compd. 2019 , 785 , 296–304. [ Google Scholar ] [ CrossRef ]

- Bang, H.T.; Yeo, K.-R.; Choi, K.J.; Jung, W.S.; Kim, S.-K. Ternary Ni-Mo-P catalysts for enhanced activity and durability in proton exchange membrane water electrolysis. Int. J. Energy Res. 2022 , 46 , 13023–13034. [ Google Scholar ] [ CrossRef ]

- Brito, J.; Restivo, J.; Sousa, J.P.S.; Spera, N.C.M.; Falcão, D.S.; Rocha, A.; Pinto, A.M.F.R.; Pereira, M.F.R.; Soares, O.S.G.P. Implementation of Transition Metal Phosphides as Pt-Free Catalysts for PEM Water Electrolysis. Energies 2022 , 15 , 1821. [ Google Scholar ] [ CrossRef ]

- Rashid, M.D.; Al Mesfer, M.K.; Naseem, H.; Danish, M. Hydrogen production by water electrolysis: A review of alkaline water electrolysis, PEM water electrolysis and high temperature water electrolysis. Int. J. Eng. Adv. Technol. 2015 , 4 , 80–93. [ Google Scholar ]

- Revankar, S.; Bindra, H. Storage and Hybridization of Nuclear Energy ; Academica Press: Cambridge, MA, USA, 2018; pp. 49–117. [ Google Scholar ]

- Medvedev, D. Trends in research and development of protonic ceramic electrolysis cells. Int. J. Hydrogen Energy 2019 , 44 , 26711–26740. [ Google Scholar ] [ CrossRef ]

- Herring, J.S.; O’Brien, J.E.; Stoots, C.M.; Hawkes, G.L.; Hartvigsen, J.J.; Shahnam, M. Progress in high-temperature electrolysis for hydrogen production using planar SOFC technology. Int. J. Hydrogen Energy 2006 , 32 , 440–450. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Younas, M.; Shafique, S.; Hafeez, A.; Javed, F.; Rehman, F. An overview of hydrogen production: Current status, potential, and challenges. Fuel 2022 , 316 , 123317. [ Google Scholar ] [ CrossRef ]

- Kim, J.; Jun, A.; Gwon, O.; Yoo, S.; Liu, M.; Shin, J.; Lim, T.H.; Kim, G. Hybrid-solid oxide electrolysis cell: A new strategy for efficient hydrogen production. Nano Energy 2018 , 44 , 121–126. [ Google Scholar ] [ CrossRef ]

- Meng, X.; Chen, M.; Gu, A.; Wu, X.; Liu, B.; Zhou, J.; Mao, Z. China’s hydrogen development strategy in the context of double carbon targets. Nat. Gas Ind. B 2022 , 9 , 521–547. [ Google Scholar ] [ CrossRef ]

- Zhang, S.; Yang, C.; Jiang, Y.; Li, P.; Xia, C. A robust fluorine-containing ceramic cathode for direct CO 2 electrolysis in solid oxide electrolysis cells. J. Energy Chem. 2023 , 77 , 300–309. [ Google Scholar ] [ CrossRef ]

- Vidales, A.G.; Choi, K.; Omanovic, S. Nickel-cobalt-oxide cathodes for hydrogen production by water electrolysis in acidic and alkaline media. Int. J. Hydrogen Energy 2018 , 43 , 12917–12928. [ Google Scholar ] [ CrossRef ]

- Vidalesa, A.G.; Millanb, N.C.; Bock, C. Modeling of anion exchange membrane water electrolyzers: The influence of operating parameters. Chem. Eng. Res. Des. 2023 , 194 , 636–648. [ Google Scholar ] [ CrossRef ]

- Vidales, A.G.; Omanovic, S. Evaluation of nickel-molybdenum-oxides as cathodes for hydrogen evolution by water electrolysis in acidic, alkaline, and neutral media. Electrochim. Acta 2018 , 262 , 115–123. [ Google Scholar ] [ CrossRef ]

- Yu, Z.; Xu, J.; Li, Y.; Wei, B.; Zhang, N.; Li, Y.; Bondarchuk, O.; Miao, H.; Araujo, A.; Wang, Z.; et al. Ultrafine oxygen-defective iridium oxide nanoclusters for efficient and durable water oxidation at high current densities in acidic media. J. Mater. Chem. A 2020 , 8 , 24743–24751. [ Google Scholar ] [ CrossRef ]

- Vidales, A.G.; Sridhar, D.; Meunier, J.-L.; Omanovic, S. Nickel oxide on directly grown carbon nanofibers for energy storage applications. J. Appl. Electrochem. 2020 , 50 , 1217–1229. [ Google Scholar ] [ CrossRef ]

- Vidales, A.G.; Dam-Quang, L.; Hong, A.; Omanovic, S. The influence of addition of iridium-oxide to nickel-molybdenumoxide cathodes on the electrocatalytic activity towards hydrogen evolution in acidic medium and on the cathode deactivation resistance. Electrochim. Acta 2019 , 302 , 198–206. [ Google Scholar ] [ CrossRef ]

| Technologies | Diaphragm | Catalyst | Electrolyte | T/°C | Efficiency/% | Advantage | Disadvantage | |

|---|---|---|---|---|---|---|---|---|

| Anode | Cathode | |||||||

| AWE | Porous materials | Ni, Co, Fe, LaCoO , LaNiO , NiCo O | Ni alloy, NiMoO | Alkaline water | 20~90 | 59~70 | Low cost, long service life, mature technology | Electrode corrosion, poor dynamic performance |

| AEM | Ni-based materials | Ni, NiFe, NiFe O , PtRu/C | Pure or alkaline water | 20~200 | 60~78 | Has the advantages of alkaline electrolysis and PEM electrolysis | Low OH conductivity and poor high-temperature stability | |

| PEM | Perfluorosulfonic acid membrane | RuO , IrO , Ir Ru O | Pt/C, MoS | Polymer, acidic electrolyte | 20~200 | 65~82 | Compact design, high responsiveness | High-cost, precious-metal catalyst |

| PCC | Perovskite ceramic | Ni ceramic | Ceramic | 500~1000 | Up to 100% | Low cost, low energy demand, and high electrochemical reaction rate | High cost, poor mechanical stability of ceramics, difficult sealing; easy to cause hydrogen leakage | |

| SOE | ceramic | La Sr MnO , LSM-YSZ | Ni-YSZ, Ni-based ceramic, perovskite | Vapor, ceramic (oxygen ion conductor) | 500~1000 °C | Up to 100% | ||

| Transition Metal-Based Electrocatalysts | Catalyst | Overpotential/mV (10 mA cm ) | Tafel Slope/mV dec | Rct/Ω |

|---|---|---|---|---|

| alloys | Fe Co @PCNs for HER [ ] | 220 | 65.5 | 47 |

| Fe Co @PCNs for HER [ ] | 260 | 53.16 | 16 | |

| B-Ti Cu for HER [ ] | 155 | 103.89 | 14.2 | |

| Mo-Ti Cu for HER [ ] | 133 | 97.37 | _ | |

| oxides | CoP@Co O @CC for HER [ ] | 73 | 85 | 70 |

| δ-MnO /SGS for HER [ ] | 80 | 42 | 140 | |

| sulfides | V-Ni S /NiOOH for HER [ ] | 154 | 94 | 5.1 |

| N-NiMoO /NiS for HER [ ] | 99 | 74.2 | _ | |

| N-NiMoO /NiS for OER [ ] | 283 | 44.3 | _ | |

| phosphides | NiFeP for OER [ ] | 313 | 44 | 4.3 |

| V-CoP/Ni P/NF for HER [ ] | 20 | 54.2 | 2.6 |

| Electrocatalysts for PEM Electrolyzer | Catalyst | Overpotential/mV (10 mA cm ) | Tafel Slope/mV dec | Rct/Ω |

|---|---|---|---|---|

| oxides | Ir Mn O for OER [ ] | 212 | 40 | 5.2 |

| Ir/ATO 70% for OER [ ] | 256 | - | - | |

| sulfides | GDL/(CNTs+FeMoS) for HER [ ] | 180 | 57 | - |

| FeS for HER [ ] | 870 mV at 1 A cm | - | - | |

| phosphides | Ni P for HER [ ] | 105 | 38 | 1.16 |

| Ni Mo P for HER [ ] | 28 | 29 | ||

| 20% FeP/CB for HER [ ] | 51 | 101 | - |

| The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

Share and Cite

Li, H.; Guo, J.; Li, Z.; Wang, J. Research Progress of Hydrogen Production Technology and Related Catalysts by Electrolysis of Water. Molecules 2023 , 28 , 5010. https://doi.org/10.3390/molecules28135010

Li H, Guo J, Li Z, Wang J. Research Progress of Hydrogen Production Technology and Related Catalysts by Electrolysis of Water. Molecules . 2023; 28(13):5010. https://doi.org/10.3390/molecules28135010

Li, Haiyao, Jun Guo, Zhishan Li, and Jinsong Wang. 2023. "Research Progress of Hydrogen Production Technology and Related Catalysts by Electrolysis of Water" Molecules 28, no. 13: 5010. https://doi.org/10.3390/molecules28135010

Article Metrics

Article access statistics, further information, mdpi initiatives, follow mdpi.

Subscribe to receive issue release notifications and newsletters from MDPI journals

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

- We're Hiring!

- Help Center

Production Technology

- Most Cited Papers

- Most Downloaded Papers

- Newest Papers

- Last »

- Finite Element Modeling Follow Following

- Sandwich composite laminates Follow Following

- Non Destructive Testing Follow Following

- Pressure Sensor Follow Following

- Postharvest Follow Following

- Molecular plant pathology Follow Following

- Plant Breeding Follow Following

- Sandwich Structures Follow Following

- Population Genetics Follow Following

- Thermoelectric Generator Follow Following

Enter the email address you signed up with and we'll email you a reset link.

- Academia.edu Journals

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

- Browse All Articles

- Newsletter Sign-Up

Production →

- 24 May 2021

Can Fabric Waste Become Fashion’s Resource?

COVID-19 worsened the textile waste crisis. Now it's time for the fashion industry to address this spiraling problem, say Geoffrey Jones and Shelly Xu. Open for comment; 0 Comments.

- 20 Oct 2015

- Working Paper Summaries

Internalizing Global Value Chains: A Firm-Level Analysis

Manufacturing activities that used to be performed in close proximity are increasingly fragmented across firms and countries. This paper provides strong evidence that considerations driven by contractual frictions critically shape firms' ownership decisions along their value chains.

- 06 Feb 2012

- Research & Ideas

Kodak: A Parable of American Competitiveness

When American companies shift pieces of their operations overseas, they run the risk of moving the expertise, innovation, and new growth opportunities just out of their reach as well, explains HBS Professor Willy Shih, who served as president of Eastman Kodak's digital imaging business for several years. Key concepts include: Outsourcing ends up chipping away at America's "industrial commons"—the collective R&D, engineering, and manufacturing capabilities that are crucial to new product development. If the United States wants to keep from slipping any further in its ability to compete on the industrial stage, the government must increase its support of scientific research and collaborate with the business and academic world. Open for comment; 0 Comments.

- 28 Mar 2011

Why Manufacturing Matters

After decades of outsourcing, America's ability to innovate and create high-tech products essential for future prosperity is on the decline, argue professors Gary Pisano and Willy Shih. Is it too late to get it back? From HBS Alumni Bulletin. Closed for comment; 0 Comments.

- 01 Mar 2010

A Golden Opportunity for Ford and GM

With Toyota caught in a downshift, competitors should make aggressive moves to capitalize, says HBS professor Bill George. For starters, they need to improve their auto lineups for the long term. He explains how Ford and GM can best navigate the industry landscape ahead. Key concepts include: For U.S. automakers to accelerate production while Toyota remains wounded is not a long-term strategy for success. The companies should cut costs while simultaneously transforming their organizations and revamping product lineups. Ford and GM could secure market share gains by investing windfall profits into making products more competitive for the next decade. In this regard, Ford has the jump on GM. Chrysler is missing a golden opportunity to revamp, reposition, and reorganize. Closed for comment; 0 Comments.

- 10 Jan 2008

- Sharpening Your Skills

Sharpening Your Skills: Operations Management

Closed for comment; 0 Comments.

- 05 Sep 2006

HBS Cases: Porsche’s Risky Roll on an SUV

Why would a company want to locate in a high-cost, high-wage economy like Germany? Porsche's unusual answer has framed two case studies by HBS professor Jeffrey Fear and colleague Carin-Isabel Knoop. Closed for comment; 0 Comments.

- Library of Congress

- Research Guides

- Science & Technology

Technical Reports & Standards Collection Guide

Introduction.

- Technical Reports Collections

- Standards Collection

- American Documentation Institute (ADI)

- Office of Scientific Research and Development (OSRD) Collection

- Synthetic Rubber Project

- Technical Translations (TT) Series

- Locating Technical Reports and Standards

- Research Assistance and Reproductions

- Online Resources and Databases

- Using the Library of Congress

- Jennifer Harbster, Head, Science Section, Researcher Engagement & General Collections Division

- Sean Bryant, Reference Librarian, Researcher Engagement & General Collections Division

- Ashley Fielder, Librarian for Medicine and Life Science. Science Section, Researcher Engagement & General Collections

- Created: September 22, 2023

Last Updated: May 7, 2024

Science & Technical Reports : Ask a Librarian

Have a question? Need assistance? Use our online form to ask a librarian for help.

Get connected to the Library’s large and diverse collections related to science, technology, and business through our Inside Adams Blog. This blog also features upcoming events and collection displays, classes and orientations, new research guides, and more.

The Library of Congress is completing a project to update and modernize Library reading room websites. As a part of the process, “The Technical Reports and Standards Collection” is in the process of being updated and migrated to this new platform. The process has not yet been completed and the guide remains subject to change.

Researchers with questions about the collection are encouraged to contact a science or business librarian using the Ask-a-Librarian: Science and Technical Reports or Ask a Librarian: Business online form, by phone, at (202) 707-5639, or in person, at the reference desk, in the Science and Business Reading Room, on the fifth floor of the Library's John Adams Building.

Technical Reports

Technical reports are designed to quickly alert researchers to recent findings and developments in scientific and technical research. These reports are issued for a variety of purposes:

- to communicate results or describe progress of a research project

- to convey background information on an emerging or critical research topic

- to provide lists of instructions or procedures for current practices

- to determine the feasibility of a technology and recommend if research should be continued (and how to evaluate any further progress made)

- to detail technical specifications (materials, functions, features, operation, market potential, etc.)

Technical reports first appeared in the early part of the 20th century. The U.S. Geological Survey (USGS) published a series of professional papers beginning in 1902, and the National Advisory Committee for Aeronautics (NACA) issued its first report in 1915. But, the format gained importance during World War II, emerged in the postwar era, and remains, to this day, a major tool for reporting progress in science and technology, as well as in education, business, and social sciences research. The names given to series of these publications vary, but are often such generic terms as "technical reports," "working papers," "research memoranda," "internal notes," "occasional papers," "discussion papers" or "gray (or grey) literature." In the physical and natural sciences, "technical report" seems to be the preferred designation. For reports dealing with business, education, and the social sciences, on the other hand, the terms "working paper," "occasional paper," and "memorandum" are often the designations of choice. Other, more specific types of technical reports include "preprints" and "reprints." Preprints generally are versions of papers issued by researchers before their final papers are published by commercial publishers. Preprints allow researchers to communicate their findings quickly, but usually have not been peer reviewed. Reprints are typically released to heighten awareness of the research being conducted in a particular field or at a single institution. The term, "technical report" encompasses all of these designations.

Since many of these publications are intended to provide just a temporary snapshot of current research in a particular field or topic, they may contain the some of following distinctions:

- Rapid communication of new research results

- Dissemination to a targeted audience.

- Detailed methodologies, in order to facilitate review of research results by others

- No peer review, though there is often another selection process for publication (grant, contract, or institutional affiliation)

- Not published by typical commercial publishers (instead reports are issued or sponsored by government agencies, professional associations, societies, councils, foundations, laboratories, universities, etc.)

- Corporate authorship, where present, is typically emphasized

Unfortunately, uncertain availability, limited print runs, and decentralized distribution patterns with little bibliographic information are also often characteristics of this literature.

The Federal Government issues many different types of technical reports. An overview of some of these can be found in a May 2001 GAO report, " Information Management: Dissemination of Technical Reports ." Government issued or sponsored reports contain an additional characteristic - they may be subject to distribution restrictions linked to their classification status. Although references to classified reports may be found in technical reports literature, the security status or limited distribution of reports may make them unavailable to the general public and to the Library as well, as the Library holds only titles in the public domain. Those interested in locating such materials can consult the U.S. Department of Justice's Freedom of Information Act site for guidance in obtaining these reports.

To enable them to be identified and located, technical reports are assigned report codes by agencies or organizations involved in their production or distribution. These codes may be referred to as "accession numbers," "agency report series numbers," "contract numbers," "grant numbers" or by other names, and include dates and individual report numbers. Typically, reports are assigned multiple codes and these codes help to identify the sponsoring agency, the organization performing the research or the organization disseminating the report. Most technical reports held by the Library of Congress are not cataloged, and, for these reports, one or more report codes is required for Library staff to check the collections for a report or to locate and retrieve it. For more information about the current Standard Technical Report Number format (STRN) see ANSI/NISO Z39.23- 1997 (S2015) Standard Technical Reports Number Format and Creation .

Standards are specifications which define products, methods, processes or practices, and are known to have existed as early as 7000 B.C., when cylindrical stones were used as units of weight in Egypt. According to Office of Management and Budget (OMB) Circular A-119 , as revised in 2016, the term "standard" or "technical standard" refers to:

- common and repeated use of rules, conditions, guidelines or characteristics for products or related processes and production methods, and related management systems practices;

- the definition of terms; classification of components; delineation of procedures; specification of dimensions, materials, performance, designs, or operations; measurement of quality and quantity in describing materials, processes, products, systems, services, or practices; test methods and sampling procedures; or descriptions of fit and measurements of size or strength; and

- terminology, symbols, packaging, marking or labeling requirements as they apply to a product, process, or production method.

Technical standards are not "professional standards of personal conduct; or institutional codes of ethics." (p. 15).

Standards are typically generated by governments or by professional associations and organizations interested in or affected by the subject matter of particular standards. For example, U.S. government standards mandated by the Fair Packaging & Labeling Act (FPLA) have standardized the labeling required for packaging in which consumer commodities is sold. Standards set the basis for determining consistent and acceptable minimum levels of reliability and safety, and are adhered to either voluntarily or as mandated by law. For a more complete overview, see the NIST report " The ABC's of Standards Activities " by Maureen A. Breitenberg (2009).

The Library of Congress standards collection includes military and other federal standards, industry standards, and a few older international standards from Russia, China, and South Africa. Material from the collection is available in various formats, including digital, print, and microform materials. The majority of the Library's standards collection held in the Science Section's Technical Reports and Standards Collection. The collection remains largely uncatalogued, and as a result, most items from this collection are not discoverable in the Library's online catalog. Inquires on Library holdings can be sent to the Science Section using the Science and Technical Reports Ask-a-Librarian form . Some standards, however, are housed in the Library's general collections and discoverable by searching the online catalog -- the ASTM standards are one example. Other standards are in custody of appropriate specialized research centers, such as the Law Library , which maintains OSHA standards and some building codes.

About the Science Section

Part of the Science & Business Reading Room at the Library of Congress, the Science Section is the starting point for conducting research at the Library of Congress in the subject areas of science, medicine and engineering. Here, reference specialists in specific subject areas of science and engineering assist patrons in formulating search strategies and gaining access to the information and materials contained in the Library's rich collections of science, medicine, and engineering materials.

- Next: Technical Reports Collections >>

- Last Updated: Jul 3, 2024 11:51 AM

- URL: https://guides.loc.gov/technical-reports

- Get 7 Days Free

Next Hydrogen to Supply Latest Generation Electrolysis Technology for Renewable Energy Ammonia Production Research

MISSISSAUGA, Ontario, Aug. 19, 2024 (GLOBE NEWSWIRE) -- Next Hydrogen Solutions Inc. (the “ Company ” or “ Next Hydrogen “) ( TSXV:NXH , OTC:NXHSF ), a designer and manufacturer of electrolyzers, is pleased to announce that it has been awarded a contract by the University of Minnesota (UMN) for its latest generation electrolysis technology to be installed at the UMN West Central Research and Outreach Center (WCROC).

The WCROC project is supported by the U.S. Department of Energy’s Advanced Research Project Agency (ARPA-E) as well as other partners including RTI International (RTI) and will include technologies from Casale, RTI and UMN to demonstrate the production of ammonia from renewable energy targeting emerging energy markets and existing agricultural markets.

Next Hydrogen will be supplying its latest third-generation Alkaline Water Electrolyzers featuring improvements in energy efficiency, current density and operating pressure. Next Hydrogen electrolyzers provide complete and responsive renewable energy load following capability needed to produce hydrogen from intermittent energy sources such as wind and solar. The system is scheduled to be operational in 2025.

The project team also includes Nutrien, GE, Nel Hydrogen, Xcel Energy, Great River Energy, Otter Tail Power Company, Runestone Electric Association, Chemtronergy, Texas Tech University, Pacifica, the Agricultural Utilization Research Institute (AURI) and Shell.

Raveel Afzaal, President and CEO of Next Hydrogen, stated, “We are very honored to be part of this exciting project and working with our existing partners Casale and GE while also forming new industry relationships. Our technology provides a compelling alternative to more expensive options for producing hydrogen from renewable energy.”

About Next Hydrogen Founded in 2007, Next Hydrogen is a designer and manufacturer of electrolyzers that use water and electricity as inputs to generate clean hydrogen for use as an energy source. Next Hydrogen’s unique cell design architecture supported by 40 patents enables high current density operations and superior dynamic response to efficiently convert intermittent renewable electricity into green hydrogen on an infrastructure scale. Following successful pilots, Next Hydrogen is scaling up its technology to deliver commercial solutions to decarbonize transportation and industrial sectors.

Contact Information

Raveel Afzaal, President and Chief Executive Officer Next Hydrogen Solutions Inc. Email: [email protected] Phone: 647-961-6620 www.nexthydrogen.com

Cautionary Statements This news release contains “forward-looking information” and “forward-looking statements”. All statements, other than statements of historical fact, are forward-looking statements and are based on expectations, estimates and projections as at the date of this news release. Any statement that involves discussions with respect to predictions, expectations, beliefs, plans, projections, objectives, assumptions, future events or performance (often but not always using phrases such as “expects”, or “does not expect”, “is expected”, “anticipates” or “does not anticipate”, “plans”, “budget”, “scheduled”, “forecasts”, “estimates”, “believes” or “intends” or variations of such words and phrases or stating that certain actions, events or results “may” or “could”, “would”, “might” or “will” be taken to occur or be achieved) are not statements of historical fact and may be forward-looking statements. Forward-looking statements are necessarily based upon a number of estimates and assumptions that, while considered reasonable, are subject to known and unknown risks, uncertainties, and other factors which may cause the actual results and future events to differ materially from those expressed or implied by such forward-looking statements. Such factors include, but are not limited to: the risks associated with the hydrogen industry in general; delays or changes in plans with respect to infrastructure development or capital expenditures; the uncertainty of estimates and projections relating to costs and expenses; failure to obtain necessary regulatory approvals; health, safety and environmental risks; uncertainties resulting from potential delays or changes in plans with respect to infrastructure developments or capital expenditures; currency exchange rate fluctuations; as well as general economic conditions, stock market volatility; and the ability to access sufficient capital. There can be no assurance that such statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on the forward-looking statements and information contained in this news release. Except as required by law, there will be no obligation to update the forward-looking statements of beliefs, opinions, projections, or other factors, should they change.

Market Updates

This election season, here are the investment questions worth asking, how to build and manage a portfolio of stocks, new 4-star stocks, markets brief: tech rebounds, small caps at discount, what’s happening in the markets this week, schwab’s kathy jones on the big mistake bond investors should avoid, where to find value in japanese stocks, 5 undervalued stocks that crushed earnings, stock picks, going into earnings, is nvidia stock a buy, a sell, or fairly valued, the best tech stocks to buy, 3 stocks to buy after they’ve sold off, 10 stocks with the largest fair value estimate increases after q2 earnings, lumen stock has been on a wild ride. is it a buy, apple, meta, and salesforce released new dividends. is it too soon to celebrate, the best reits to buy, applied materials earnings: we like the firm’s growth opportunity, sponsor center.

A review of the current situation and prospects for nanofluids to improve solar still performance

- Open access

- Published: 17 August 2024

Cite this article

You have full access to this open access article

- Farhan Lafta Rashid 1 ,

- Mudhar A. Al-Obaidi 2 , 3 ,

- Hayder I. Mohammed 4 ,

- Hussein Togun 5 ,

- Shabbir Ahmad 6 , 7 &

- Arman Ameen ORCID: orcid.org/0000-0002-8349-6659 8

71 Accesses

Explore all metrics

Drinking water production has been thrust to the forefront of global issues as a direct result of the critical need for access to clean water and the expanding environmental difficulties. Solar stills are becoming an increasingly popular technology for the purification of water since they provide a greener and more cost-effective alternative to the production of distilled water of a high standard. Recent research has focused on the incorporation of nanofluids, which are suspensions of metallic or non-metallic nanoparticles, into base fluids such as water and oil in the hopes of further increasing the effectiveness of solar distillation. This novel technique intends to improve thermophysical and evaporation parameters, which will eventually lead to greater production in solar stills. In this paper, a complete overview of the most recent developments in the use of nanofluids in solar still technology is presented. This research investigates the potential of nanofluid-filled solar still systems by focusing on their one-of-a-kind qualities. These qualities include increased thermophysical properties, better thermal conductivity, and enhanced thermal absorptivity. The innovative nature of this method is highlighted by the fact that the use of nanofluids in active solar stills has proven a decrease in the amount of pumping power that is required. For instance, it has been ascertained that the inclusion of carbon quantum dots nanofluids to a solar still can expressively improve the water production, boosting the output by 57.9% to 823 mL compared to the 521 mL produced by a conventional still. Also, using a concentration of 0.9%, Al 2 O 3 , TiO 2 , CuO nanofluids and multiwall carbon nanotubes can boost the water production by 11.57%, 7.16%, 6.32%, and 4.66%, respectively, if compared to a solar still without nanofluids. This study serves as a pioneering examination of the future possibilities of nanofluid-enabled solar still systems, shining light on a transformational route toward environmentally friendly and effective water purification technologies. In light of these astonishing discoveries, this research serves as a pioneering exploration of the future prospects of nanofluid-enabled solar desalination units.

Similar content being viewed by others

Advancement in solar still integration with phase change materials-based TES systems and nanofluid for water and wastewater treatment applications

Advances in Solar Desalination System by the Application of Nanotechnology

Solar Distiller Unit Loaded with Nanofluid—A Short Review

Explore related subjects.

- Environmental Chemistry

Avoid common mistakes on your manuscript.

Introduction

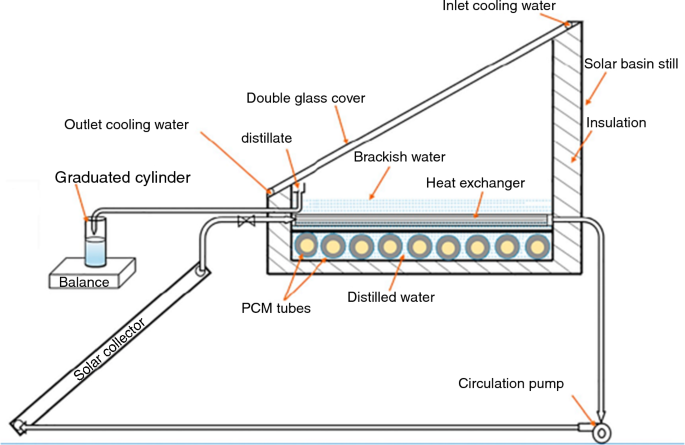

As the global population rises, there is a growing need for freshwater, yet only around 0.5% of that supply is accessible, leading to rapid depletion. As a result, there has been a rise in support for developing methods to treat the plentiful salt water so that it may be used for human consumption, and industrial and agriculture applications [ 1 , 2 ]. Solar desalination relies on two plentiful resources practically everywhere on Earth (salt water and sunlight) and is thus one of the effective natural solutions [ 3 , 4 ]. Solar still (SS) is one of the most effective desalination methods because of its cheap operational and maintenance costs, ease of building, and little environmental impact [ 5 , 6 ]. Conventional solar still (CSS) is simply designed to use solar energy to purify water through evaporation and condensation steps. The four constituents of a solar still modules are the basin (a container that holds the saline water), cover (a glass or plastic that allows sunlight to enter the basin), condenser (to condense water vapor into fresh water), and a collection trough (to collect the condensed fresh water) (Fig. 1 ). However, conventional sun stills lose heat to the environment and need heat to successfully heat the basin water, resulting in poor production [ 7 , 8 , 9 , 10 , 11 , 12 ]. Condensation heat loss to the surrounding air significantly reduces solar power's poor efficiency [ 13 ]. Condensers [ 14 , 15 , 16 ] and multiple effect stills [ 17 ] may be used to eliminate this effect. Reddy et al. (1983) [ 18 ] found that adding a condenser to wick solar increased output productivity by 15–25%. Traditional multi-wick double-slope solar stills were the focus of Pal et al. (2018) [ 19 ] in-depth theoretical investigation. They achieved a 35% energy efficiency and an exergy efficiency of 3.83%. To boost the efficiency of both systems, wick solar stills were fed with water from a humidification and dehumidification desalinating unit [ 20 ]. Nanofluid, in which nanoparticles are mixed with the basic fluid (saline water), is another method for increasing SS output. Specifically, nanofluids are engineered fluids that encompass suspended nanoparticles (typically 1-100 nm in size). Increased evaporation rate and productivity may be attributed to the nanoparticles ability to boost thermal conductivity and heat transmission. The mechanism of enhancement heat transfer in the solar stills with the presence of nanoparticles is basically explained as follows; the nanoparticles have greater thermal conductivities than the basic fluid, which allows for quicker heat transfer from the basin to the water vapor. Also, the existence of nanoparticles can create micro-convection currents within the fluid, which improves heat transfer by increasing the surface area exposed to the heat source. Lastly, some nanoparticles can absorb solar radiation and convert it to heat, which would increase the water temperature [ 21 , 22 , 23 ]. The consequence of these reasons can undoubtedly maximize the utilization of solar energy besides improving the amount of water generated by a solar still. For instance, diesel and biodiesel mix benefit greatly from nanoparticle's improved emission and combustion behavior [ 24 ]. SC1 (supramolecular complex) nanofluid improved diesel engine performance by about 14.8–20.52% due to its effect on the thermal brake. In addition, [ 25 ] discusses a review that demonstrates how various nanoparticles influence the thermal and electrical performance of photovoltaic-thermal (PV/T) systems.

A schematic representation of a solar still [ 4 ]

Numerous experimental and computational studies demonstrating the performance of the SS system with various nanoparticles of varying shapes and sizes have been published in recent years. Most of these nanoparticles have high thermal conductivity, and this property has been shown to have beneficial implications on SS performance. The impact of Magnesium Oxide (MgO) and Titanium dioxide (TiO 2 ) nanoparticles on the efficiency of stepwise SS was the subject of an experiment achieved by Panchal et al. (2019) [ 26 ]. Nanoparticle concentrations ranging between 0.1 and 0.2% are used in the experiment. MgO and TiO 2 at a concentration of 0.2% were shown to increase still production by 45.8% and 20.4%, respectively.

Reviewing current strategies developed to improve solar still performance, Alenezi and Alabaiadly (2023) [ 27 ] focused on methods that use non-metallic nanofluids as the foundation fluid. Al 2 O 3 , CuO, ZnO, and TiO 2 are the nanomaterials examined here. It was also clear that using ZnO in a solar-still desalination system led to a significant rise in pure water production and prompted gains in efficiency and productivity. Sangeetha et al. (2023) [ 28 ] constructed the review process on nanofluid structures, and phase change material (PCM) is executed in the internal heat transfer process. With the benefit of a global challenge, the PCM nanofluid used in Double slope solar still (DSSS) is concentrated on prospects based on applying persuasive initiatives. It has been perceived that the amount of DSSS distillate produced meaningfully upsurges when using an improvement strategy for PCMNF in conjunction with DSSS.

Recent advances in the use of nano based PCM and pure nanoparticles as a thermal storage medium in solar stills were reviewed by Nagaraju et al. (2022) [ 29 ]. Due to its increased solidification and melting rates, PCM subjected to nanotechnology is attracting and diverting the focus away from the significant critical barrier of PCM's poor heat conductivity in industrial and home applications. The essay highlights the benefits of utilizing nanoparticles and PCM with nanoparticles to improve the thermal performance of solar stills.

The existing literature indicates a notable absence of comprehensive investigations into the integration of nanofluids in solar still systems. Although some categorization of systems utilizing nanofluids, such as pyramid solar stills, single and slope solar stills, traditional solar stills, wick type solar stills, triangle solar stills, and stepped type solar stills, has been undertaken, there remains a shortage of comprehensive studies in this area. This study aims to address this research gap by providing an in-depth analysis of the utilization of nanofluids in solar stills. Through an exhaustive examination of the most recent existing body of literature published between 2019 and 2023, this study seeks to shed light on key challenges and limitations associated with nanofluid integration. By offering detailed descriptions of various technical, research, and development approaches related to nanofluids, this article provides a novel perspective on their potential application in solar still systems. The outcomes of this review serve as a roadmap for future investigations, equipping researchers with crucial insights into the plethora of unanswered questions and challenges associated with nanofluid usage in solar distillation. This research endeavor aspires to pave the way for further exploration and advancements in harnessing nanofluids to augment the efficiency and performance of solar stills, eventually contributing to the sustainable development of water purification and freshwater generation technologies.

Review method

A methodical literature review is directed to deliver an overview of the studies that explored the use of nanofluids for improving the efficiency of solar desalination systems such as the pyramid solar still, desalination units, single-slope solar still, double-slope solar still, conventional solar still, wick type solar still, triangular solar still, and stepped solar still. The review is accomplished by analytically inspecting the existed academic literature. The search was conducted using the terms solar still, desalination, nanofluids, productivity boost, and portable water. Despite there being no limitations on when the articles needed to be published, attention was given to just take account of the most recent articles published between 2019 and 2023 to discourse the most cutting-edge research.

Pyramid solar still