Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- 12 July 2023

Plastic waste is everywhere — and countries must be held accountable for reducing it

You have full access to this article via your institution.

Plastic waste is damaging ecosystems around the world. Credit: Mark Rightmire/MediaNews Group/Orange County Register/Getty

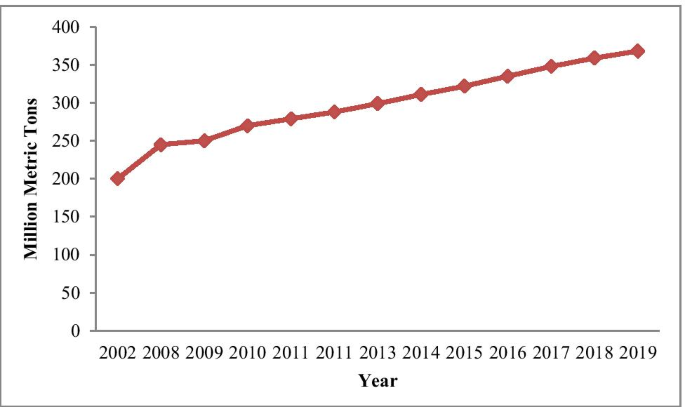

Globally, some 400 million tonnes of plastic waste are produced each year 1 . Plastics have infiltrated some of the planet’s most remote and pristine areas, as two papers published in Nature show to dramatic effect 2 , 3 .

Veronica Nava and her colleagues systematically assess the extent of plastic contamination in diverse freshwater lakes and reservoirs across 23 countries , and find them to be widely contaminated with plastic 2 . Meanwhile, Hudson Pinheiro and his colleagues show that larger pieces of plastic litter, known as macroplastics, represent the largest share of anthropogenic debris found in shallow and deep coral reefs at 25 locations across the Pacific, Atlantic and Indian ocean basins. Even the deeper reefs, lying at depths of 30–150 metres, were found to be polluted; until now, the impact of plastics on these reefs has been little studied 3 .

Both studies will be important to talks, now under way at the United Nations, on a treaty to eliminate plastic pollution. This is an ambitious goal that will require a radical rethink of plastics production, recycling, remediation and disposal. Experience gained from decades of UN environmental treaties shows that trusted and effective measurement and compliance mechanisms are as important as the agreements themselves. So far, however, the negotiations do not include a specific plan to hold countries accountable for the pledges and promises they make on behalf of their plastics producers, exporters and recyclers. It is clear that this must change — and fast.

Multi-level problem

The research published this week highlights the multi-level problem that negotiators face. Pinheiro and his colleagues found debris in 77 of the 84 coral reef sites they surveyed globally. Larger pieces of debris, bigger than 5 centimetres across — mainly discarded or broken fishing equipment — were more prevalent in deeper reefs. This highlights complex trade-offs that treaty negotiators will have to grapple with to deliver a comprehensive solution to the plastics problem. Simply banning plastic nets and other fishing gear could harm livelihoods. Subsidies or incentives might be needed to enable communities that rely on fishing to switch from using gear that causes damage to deep reefs.

Large-scale collaborations uncover global extent of plastic pollution

The study by Nava and her colleagues highlights another facet of any meaningful treaty: getting measurements right. Countries will need to discuss and agree a standard or system for how they measure plastic pollution. Nava et al. developed a protocol for categorizing and measuring plastic pollution in freshwater samples and applied it to samples collected at the surface of 38 lakes and reservoirs, most of them in the Northern Hemisphere. The authors also collected data on the size of the population near each lake, the lake’s depth and how much of the land supplying inflow water is urban. Plastics in the samples were classified by shape, colour and size, and a subset were analysed using spectroscopic methods to identify the chemical composition of their polymers. This and other knowledge needs to feed into treaty talks.

The plastics treaty is on a supercharged schedule. Talks began in March 2022 and are due to conclude with a final text in 2024. If that happens, countries are expected to incorporate the treaty into national laws in 2025.

Environmental treaties often take between 5 and 15 years to complete, and accelerating the process could compel nations to focus on the essentials. However, at the most recent negotiating session, which concluded last month in Paris, countries spent most of the week discussing (and struggling to agree on) how they would make decisions. To adhere to the rapid timetable, subsequent sessions will need to get down to detail more quickly. But a downside of a fast-track approach is that there is less time for researchers and campaigners to influence the process.

Protecting the ocean requires better progress metrics

The talks are being organized by the UN Environment Programme (UNEP), based in Nairobi. It is inviting observers, including researchers, to make written submissions by 15 August, ahead of the publication of the treaty’s first draft text, or ‘zero draft’. Researchers should take this opportunity to urge negotiators to establish an expert group on measurement and compliance as part of the talks.

UNEP told Nature that there is no dedicated expert group looking at measurement or accountability. However, a representative said that negotiators will “consider how other multilateral agreements provide for monitoring and suggest best practice”. Studying how other agreements manage monitoring is important, but monitoring is not the same thing as compliance. There is a risk that, in a rush to meet the timetable, negotiators will settle for a treaty that demands little or nothing in the way of compliance.

For the treaty negotiations to be successful, countries must commit to being held accountable. Not having a group within the negotiations charged with ensuring measurement and compliance could be a costly error. The time between now and the next session, due to be held in Nairobi in November, offers a valuable and urgent opportunity for researchers to get their voices heard — so that we can finally start to reduce the stark toll of plastic pollution on the global environment.

Nature 619 , 222 (2023)

doi: https://doi.org/10.1038/d41586-023-02252-x

Lampitt, R. S. et al. Nature Commun. 14 , 2849 (2023).

Article PubMed Google Scholar

Nava, V. et al. Nature 619 , 317–322 (2023).

Article Google Scholar

Pinheiro, H. T. et al. Nature 619 , 311–316 (2023).

Download references

Reprints and permissions

Related Articles

Chemistry can help make plastics sustainable — but it isn’t the whole solution

- Environmental sciences

- Green chemistry

Local politicians have opened up Europe’s largest marine reserve for commercial fishing

Correspondence 27 AUG 24

The meaning of the Anthropocene: why it matters even without a formal geological definition

Comment 26 AUG 24

Effective realization of abatement measures can reduce HFC-23 emissions

Article 21 AUG 24

How South Africa can move on from power cuts

World View 06 AUG 24

India budget: Modi bets big on nuclear energy and space

News 25 JUL 24

Selective lignin arylation for biomass fractionation and benign bisphenols

Article 29 MAY 24

Japan moves to halt long-term postgraduate decline by tripling number of PhD graduates

Nature Index 29 AUG 24

Urgently clarify how AI can be used in medicine under new EU law

Global Faculty Recruitment of School of Life Sciences, Tsinghua University

The School of Life Sciences at Tsinghua University invites applications for tenure-track or tenured faculty positions at all ranks (Assistant/Ass...

Beijing, China

Tsinghua University (The School of Life Sciences)

Tenure-Track/Tenured Faculty Positions

Tenure-Track/Tenured Faculty Positions in the fields of energy and resources.

Suzhou, Jiangsu, China

School of Sustainable Energy and Resources at Nanjing University

ATLAS - Joint PhD Program from BioNTech and TRON with a focus on translational medicine

5 PhD positions for ATLAS, the joint PhD Program from BioNTech and TRON with a focus on translational medicine.

Mainz, Rheinland-Pfalz (DE)

Translational Oncology (TRON) Mainz

Alzheimer's Disease (AD) Researcher/Associate Researcher

Xiaoliang Sunney XIE’s Group is recruiting researchers specializing in Alzheimer's disease (AD).

Changping Laboratory

Supervisory Bioinformatics Specialist CTG Program Head

The National Library of Medicine (NLM) is a global leader in biomedical informatics and computational health data science and the world’s largest b...

Bethesda, Maryland (US)

National Library of Medicine, National Center for Biotechnology Information

Sign up for the Nature Briefing newsletter — what matters in science, free to your inbox daily.

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

IEEE Account

- Change Username/Password

- Update Address

Purchase Details

- Payment Options

- Order History

- View Purchased Documents

Profile Information

- Communications Preferences

- Profession and Education

- Technical Interests

- US & Canada: +1 800 678 4333

- Worldwide: +1 732 981 0060

- Contact & Support

- About IEEE Xplore

- Accessibility

- Terms of Use

- Nondiscrimination Policy

- Privacy & Opting Out of Cookies

A not-for-profit organization, IEEE is the world's largest technical professional organization dedicated to advancing technology for the benefit of humanity. © Copyright 2024 IEEE - All rights reserved. Use of this web site signifies your agreement to the terms and conditions.

Information

- Author Services

Initiatives

You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

All articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer to https://www.mdpi.com/openaccess .

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

Original Submission Date Received: .

- Active Journals

- Find a Journal

- Proceedings Series

- For Authors

- For Reviewers

- For Editors

- For Librarians

- For Publishers

- For Societies

- For Conference Organizers

- Open Access Policy

- Institutional Open Access Program

- Special Issues Guidelines

- Editorial Process

- Research and Publication Ethics

- Article Processing Charges

- Testimonials

- Preprints.org

- SciProfiles

- Encyclopedia

Article Menu

- Subscribe SciFeed

- Recommended Articles

- Google Scholar

- on Google Scholar

- Table of Contents

Find support for a specific problem in the support section of our website.

Please let us know what you think of our products and services.

Visit our dedicated information section to learn more about MDPI.

JSmol Viewer

Plastic waste management: a review of existing life cycle assessment studies.

1. Introduction

1.1. plastics, 1.2. recycling of plastic, 1.3. waste management, 1.4. legal requirements for waste recycling.

- Establish a waste reduction research and development program;

- Direct several federal agencies in developing strategies to reduce waste;

- Develop standards for plastic recycling technologies.

1.5. Life Cycle Assessment

- Goal and scope definition;

- Life Cycle Inventory Analysis (LCI);

- Life Cycle Impact Assessment (LCIA);

- Interpretation.

1.6. Aims and Objectives

2. materials and methods, 2.1. selection criteria.

- An original research article focusing on environmental impacts associated with at least one plastic recycling technology.

- Contains a well-described methodology with a clearly defined functional unit, goal and scope, and system boundary.

- Results are quantified and tabulated as defined impact potentials covering at least two different categories.

2.2. Assessment Process

2.2.1. goal and scope.

- Types of plastics included some studies focus on a broad range of plastics, while others were restricted to just one polymer (for example, PET) or product type (example, plastic films).

- Study extent: Some studies cover the entire lifespan of the plastics; others are more focused on specific aspects of the process.

2.2.2. Functional Unit (FU)

- Type of waste (general waste, plastic waste, or specified waste type);

- Quantifier of waste amount (specific mass, volume).

2.2.3. Impact Category

- Different studies may choose to investigate and assess different categories;

- The result for an impact category may not be comparable across studies if the system boundaries, functional units or other factors are different.

2.2.4. System Boundary

- Study scope (included/excluded processes);

- Geographical area (the environmental impact may vary in different locations due to varying processes, environments, infrastructures, and ecosystem sensitivities);

- Time horizon (what timeframe is considered for pollutant degradation pathways and technologies);

- Boundaries with other life cycles (how does the process interact with other processes such as plastic production, consumer use, recycling technologies).

2.2.5. Sensitivity and Uncertainty Analysis

3.1. comparison of lca goals and scopes, 3.2. comparison of functional units, 3.3. comparison of impact assessment categories, 3.4. comparison of system boundaries, 3.5. comparison of geographical context, 3.6. sensitivity and uncertainty analysis, 4. discussion, 4.1. comparable studies, 4.2. other studies, 4.3. summary, 5. conclusions, author contributions, institutional review board statement, informed consent statement, data availability statement, conflicts of interest.

- Lebreton, L.; van der Zwet, J.; Damsteeg, J.W.; Slat, B.; Andrady, A.; Reisser, J. River plastic emissions to the world’s oceans. Nat. Commun. 2017 , 8 , 15611. [ Google Scholar ] [ CrossRef ]

- Lebreton, L.; Slat, B.; Ferrari, F.; Sainte-Rose, B.; Aitken, J.; Marthouse, R.; Hajbane, S.; Cunsolo, S.; Schwarz, A.; Levivier, A.; et al. Evidence that the Great Pacific Garbage Patch is rapidly accumulating plastic. Sci. Rep. 2018 , 8 , 4666. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Joachimiak-Lechman, K.; Garstecki, D.; Konopczyński, M.; Lewandowska, A. Implementation of life cycle based tools in the circular economy context—Case study of plastic waste. Sustainability 2020 , 12 , 9938. [ Google Scholar ] [ CrossRef ]

- Antelava, A.; Damilos, S.; Hafeez, S.; Manos, G.; Al-Salem, S.M.; Sharma, B.; Kohli, K.K.; Constantinou, A. Plastic Solid Waste (PSW) in the Context of Life Cycle Assessment (LCA) and sustainable management. Environ. Manag. 2019 , 64 , 230–244. [ Google Scholar ] [ CrossRef ] [ PubMed ] [ Green Version ]

- Bernardo, C.A.; Simões, C.; Pinto, L. Environmental and economic life cycle analysis of plastic waste management options. A review. AIP Conf. Proc. 2016 , 1779 , 140001. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Lazarevic, D.; Aoustin, E.; Buclet, N.; Brandt, N. Plastic Waste Management in the context of a European recycling society. Resour. Conserv. Recycl. 2010 , 55 , 246–259. [ Google Scholar ] [ CrossRef ]

- Foschi, E.; Zanni, S.; Bonoli, A. Combining Eco-Design and LCA as decision-making process to prevent plastics in packaging application. Sustainability 2020 , 12 , 9738. [ Google Scholar ] [ CrossRef ]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017 , 3 , e1700782. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015 , 347 , 768–771. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Aryan, Y.; Yadav, P.; Samadder, S.R. Life Cycle Assessment of the existing and proposed plastic waste management options in India: A case study. J. Clean. Prod. 2019 , 211 , 1268–1283. [ Google Scholar ] [ CrossRef ]

- United States Environmental Protection Agency. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/plastics-material-specific-data (accessed on 6 December 2020).

- BPF. How Is Plastic Made? A Simple Step-by-Step Explanation ; British Plastics Federation: London, UK, 2021. [ Google Scholar ]

- Life Cycle Assessment for a Plastic and a Glass Product. Available online: https://lifecycleofplastic.wordpress.com (accessed on 17 April 2021).

- PP. Plastic Pollution-The Life Cycle of a Plastic Product: Reworking and Looping the Cycle. 2021. Available online: https://plasticpollutionblogsite.wordpress.com/2016/09/21/the-life-cycle-of-a-plastic-product-part-2-reworking-the-cycle/ (accessed on 17 April 2021).

- Chen, L.; Pelton, R.E.; Smith, T.M. Comparative life cycle assessment of fossil and bio-based polyethylene terephthalate (PET) bottles. J. Clean. Prod. 2016 , 137 , 667–676. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Verma, R.; Vinoda, K.; Papireddy, M.; Gowda, A. Toxic pollutants from plastic waste-a review. Procedia Environ. Sci. 2016 , 35 , 701–708. [ Google Scholar ] [ CrossRef ]

- Faraca, G.; Martinez-Sanchez, V.; Astrup, T.F. Environmental life cycle cost assessment: Recycling of hard plastic waste collected at Danish recycling centres. Resour. Conserv. Recycl. 2019 , 143 , 299–309. [ Google Scholar ] [ CrossRef ]

- Hou, P.; Xu, Y.; Taiebat, M.; Lastoskie, C.; Miller, S.A.; Xu, M. Life cycle assessment of end-of-life treatments for plastic film waste. J. Clean. Prod. 2018 , 201 , 1052–1060. [ Google Scholar ] [ CrossRef ]

- Vora, N.; Christensen, P.R.; Demarteau, J.; Baral, N.R.; Keasling, J.D.; Helms, B.A.; Scown, C.D. Leveling the cost and carbon footprint of circular polymers that are chemically recycled to monomer. Sci. Adv. 2021 , 7 , 15. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Guinee, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buon- amici, R.; Ekvall, T.; Rydberg, T. Life cycle assessment: Past, present, and future. Environ. Sci. Technol. 2011 , 45 , 90–96. [ Google Scholar ] [ CrossRef ]

- Heijungs, R.; Guin’ee, J.; Huppes, G.; Lankreijer, R.; Udo de Haes, H.; Wegener Sleeswijk, A.; Ansems, A.; Eggels, P.; Van Duin, R.; Goede, H. Environmental Life Cycle Assessment of Products: Background and Guide ; Centre of Environmental Science (CML): Leiden, The Netherlands, 1992; p. 96. [ Google Scholar ]

- Standard ISO. 14040 (2006) NF EN ISO 14040: 2006-Environmental Management-Life Cycle Assessment-Principles and FrameWork. 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 26 April 2021).

- Standard ISO. 14044 (2006) NF EN ISO 14044: 2006–Environmental Management–Life Cycle Assessment–Requirements and Guidelines. 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 26 April 2021).

- Klöpffer, W. The critical review of life cycle assessment studies according to ISO 14040 and 14044. Int. J. Life Cycle Assess. 2012 , 17 , 1087–1093. [ Google Scholar ] [ CrossRef ]

- ILCD Handbook: Analysis of Existing Environmental Impact Assessment Methodologies for Use in Life Cycle Assessment ; Joint Research Centre-European Commission: Ispra, Italy, 2010.

- Bare, J.C.; Hofstetter, P.; Pennington, D.W.; De Haes, H.A.U. Midpoints versus endpoints: The sacrifices and benefits. Int. J. Life Cycle Assess. 2000 , 5 , 319. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Chilton, T.; Burnley, S.; Nesaratnam, S. A life cycle assessment of the closed-loop recycling and thermal recovery of post-consumer PET. Resour. Conserv. Recycl. 2010 , 54 , 1241–1249. [ Google Scholar ] [ CrossRef ]

- Komly, C.E.; Azzaro-Pantel, C.; Hubert, A.; Pibouleau, L.; Archambault, V. Multiobjective waste management optimization strategy coupling life cycle assessment and genetic algorithms: Application to PET bottles. Resour. Conserv. Recycl. 2012 , 69 , 66–81. [ Google Scholar ] [ CrossRef ] [ Green Version ]

- Al-Maaded, M.; Madi, N.; Kahraman, R.; Hodzic, A.; Ozerkan, N. An overview of solid waste management and plastic recycling in Qatar. J. Polym. Environ. 2012 , 20 , 186–194. [ Google Scholar ] [ CrossRef ]

- Nishijima, A.; Nakatani, J.; Yamamoto, K.; Nakajima, F. Life cycle assessment of integrated recycling schemes for plastic containers and packaging with consideration of resin composition. J. Mater. Cycles Waste Manag. 2012 , 14 , 52–64. [ Google Scholar ] [ CrossRef ]

- Rajendran, S.; Hodzic, A.; Scelsi, L.; Hayes, S.; Soutis, C.; Alma’Adeed, M.; Kahraman, R. Plastics recycling: Insights into life cycle impact assessment methods. Plast. Rubber Compos. 2013 , 42 , 1–10. [ Google Scholar ] [ CrossRef ]

- Al-Salem, S.; Evangelisti, S.; Lettieri, P. Life cycle assessment of alternative technologies for municipal solid waste and plastic solid waste management in the Greater London area. Chem. Eng. J. 2014 , 244 , 391–402. [ Google Scholar ] [ CrossRef ]

- Ferreira, S.; Cabral, M.; da Cruz, N.F.; Simões, P.; Marques, R.C. Life cycle assessment of a packaging waste recycling system in Portugal. Waste Manag. 2014 , 34 , 1725–1735. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Rigamonti, L.; Grosso, M.; Møller, J.; Sanchez, V.M.; Magnani, S.; Christensen, T.H. Environmental evaluation of plastic waste management scenarios. Resour. Conserv. Recycl. 2014 , 85 , 42–53. [ Google Scholar ] [ CrossRef ]

- Wäger, P.A.; Hischier, R. Life cycle assessment of post-consumer plastics production from waste electrical and electronic equipment (WEEE) treatment residues in a Central European plastics recycling plant. Sci. Total Environ. 2015 , 529 , 158–167. [ Google Scholar ] [ CrossRef ]

- Gu, F.; Guo, J.; Zhang, W.; Summers, P.A.; Hall, P. From waste plastics to industrial raw materials: A life cycle assessment of mechanical plastic recycling practice based on a real-world case study. Sci. Total Environ. 2017 , 601 , 1192–1207. [ Google Scholar ] [ CrossRef ]

- Khoo, H.H. LCA of plastic waste recovery into recycled materials, energy and fuels in Singapore. Resour. Conserv. Recycl. 2019 , 145 , 67–77. [ Google Scholar ] [ CrossRef ]

- Chen, Y.; Cui, Z.; Cui, X.; Liu, W.; Wang, X.; Li, X.; Li, S. Life cycle assessment of end-of-life treatments of waste plastics in China. Resour. Conserv. Recycl. 2019 , 146 , 348–357. [ Google Scholar ] [ CrossRef ]

Click here to enlarge figure

| Type | Abbreviation | Description | Example Use |

|---|---|---|---|

| Polyethylene Terephthalate | PET/PETE | Polyester extruded and molded. Clear, strong, and lightweight | Plastic bottles (water, soft drinks) and as packaging for many other consumer products |

| High-Density Polyethylene | HDPE | Intermediate level of opacity, less stretchable compared to LDPE | Milk jugs, water bottles, shampoo bottles, motor oil containers, plant pots, buckets, toys |

| Polyvinyl chloride | PVC | Strong, lightweight. Can be made more flexible by adding plasticizers | Plumbing pipes, doors, windows, credit cards, cable sheathing, garden hoses, toys |

| Low-Density Polyethylene | LDPE | High clarity and moderate stretch | Plastic bags, squeezable bottles, food containers, bubble wrap, disposable cups, coatings for paper cartons |

| Polypropylene | PP | Durable with a smooth finish. | Bottle tops, yogurt and margarine containers, drinking straws, hot food containers, car parts, disposable diapers |

| Polystyrene | PS | Economical plastics with a certain rigidity | Disposable foam cups, take-out food containers, plastic cutlery, coat hangers, foam packaging |

| Polycarbonate | PC | Transparent, high impact resistance | Eye protection, shatterproof glazing, UV resistant lenses, barriers, fences |

| Type | Description | Disadvantages |

|---|---|---|

| Primary | Re-extruding the discarded plastic wastes from industries. As a high degree of homogeneity is required by this process, post-consumer plastic wastes were not considered. | Not suitable for post-consumer plastic wastes |

| Secondary | Mechanical recycling of the recovered plastics. These are the plastic wastes recovered from the (retail) consumers, sorted and reprocessed to produce single polymer pellets, granules, or flakes intended to replace the virgin plastic in the market. The process primarily involves melting and extruding the plastic without altering the chemical composition of the plastics significantly. | Plastic wastes must be clean and dry, ideally consisting of only one type of plastic polymer |

| Tertiary | Feedstock chemical recycling, where the plastic wastes undergo pyrolysis and/or hydrolysis processes where it depolymerizes and breaks down into monomers and other basic chemical elements that can be used as raw materials for primary plastic production. This also results in the production of oil and gas which can be used as a fuel, usually used to power the recycling plant itself. | High energy consumption due to head requirements. Uses chemical reagents with negative environmental impacts |

| Category | Description |

|---|---|

| Global Warming Potential (GWP) | Increasing temperature in the lower atmosphere, caused by the emission of greenhouse gases (e.g., CO , methane, nitrous oxides) which reflect or absorb infrared radiations reflecting off Earth’s surface. This causes regional climate changes, melting of polar glaciers, and sea-level rise. It is the most widely used impact factor for LCA studies and is also identified as Climate Change in studies using ReCiPe (Endpoint) or Ecoindica-tor99. Expressed as kilograms of CO equivalent. |

| Ecotoxicity Potential (ETP) | Ecosystem impact of the emission of toxic substances to air, water, and soil can have a global, continental, or local scale. The plastic industry contributes to the toxicity caused by emissions of toxic substances (e.g., diethyl phthalate). Some LCIA methods, such as ReCiPe, combine the toxicity affecting air, water, and soil to one parameter, others, such as CML, divide these into terrestrial, freshwater, or marine ecotoxicity potentials. Normalized and expressed as 1,4-dichlorobenzene (DB) equivalents/kg emission. |

| Acidification Potential (AP) | Impact of processes that cause acid rain and reduced vegetation, usually caused by the emission of chemicals (e.g., sulfur oxides, nitrogen oxides, and ammonia). Acidification can reduce the pH of soils, freshwater resources, and seas. Terrestrial Acidification Potential (TAP) is a subcategory related to acidification of soil, caused by landfilling of plastic and/or other chemicals. Expressed as kilograms of SO equivalents. |

| Abiotic Depletion (elements) (AD) | Use of natural resources, including minerals and energy, but excluding fossil fuels. The natural resources can be renewable (quickly replenished) or nonrenewable (not replenished within 500 years). Expressed as kilograms of Antimony equivalent (kg Sb-eq). |

| Abiotic Depletion (Fossil Fuels) (FDP) | The use of fossil fuels (non-renewable), this category is also known as Fossil Depletion Potential. Expressed in MJ of energy produced. |

| Eutrophication Potential (EP) | The enrichment of aquatic ecosystems with nutritional elements (e.g., nitrogen and phosphorus compounds). Causes excessive algae growth, which releases toxins harmful to higher energy forms, and reduces light and oxygen in the water, harming other aquatic life. Expressed as kilograms of PO3− equivalents. |

| Human Toxicity (HT) | The effect of toxic substances on human health is sometimes expressed in subcategories of HT (cancer) and HT (non-cancer) depending on whether the substance is carcinogenic. Expressed as 1,4-DB equivalents/kg emission of substance. |

| Photochemical Oxidation Potential (POP) | Formation of ozone at the troposphere (ground level), also known as Photochemical Oxidant Formation, (Photochemical) Ozone Creation, or Ozone Formation. The photochemical oxidants are secondary air pollutants (also called summer smog) formed by the reaction of sunlight on carbon monoxide, and reactive hydrocarbons (e.g., ethane) in the presence of nitrogen oxides. Expressed as kilograms of ethane equivalent. |

| (Stratospheric) Ozone Depletion POTENTIAL (ODP) | Emissions of stable substances containing Chlorine or Bromine to air can reach the stratosphere and destroy the ozone layer. Depletion of the ozone layer increased the UV rays reaching the earth’s surface, which is harmful to humans, plants, and animals. Expressed as kilograms of CFC-11 equivalents. |

| Particulate Matter Formation Potential (PMFP) | Measure of particulate matter (PM10) release to the air. This consists of respirable particles with a diameter < 10 µm, that are hazardous to human health. Primary particles (e.g., nitrogen oxides, sulfur oxides, ammonia) react to form larger diameter secondary substances (e.g., ammonium nitrate, ammonium sulfate). Expressed as kilograms of PM10 equivalent. |

| Publication | Plastic Type | Functional Unit | LCIA Technique | Impact Categories |

|---|---|---|---|---|

| 2010 T. Chilton et al. [ ] | PET soft drink bottles. | 1 tonne | Eco-indicator | GWP, ETP, AP, FDP, EP, Carcinogens, Respiratory organics, Respiratory inorganics, Radiation, |

| 2012 C.-E. Komly et al. [ ] | PET bottles | M kg | CML 2001 | GWP, ETP (freshwater and terrestrial), AP, AD, EP, HT, POP |

| 2012 M. Al-Maaded et al. [ ] | Mixed plastic waste | 10 kg | CML 2001 | GWP, AD, HT |

| 2012 Nishijima et al. [ ] | Waste plastic container | 1 kg | GWP, FDP | |

| 2013 S Rajendran et al. [ ] | Polyolefin plastic wastes | 1 tonne | Eco-indicator, EDIP | GWP, ETP, AP, AD, EP, HT, POP, ODP, hazardous and radioactive waste, slags/ashes, bulk waste |

| 2014 S.M. Al-Salem et al. [ ] | Plastics mix (VCC feed), PO (PP + PE), PVC | 1000 tonnes per annum | CML 2001 | GWP, ETP, AP, POP |

| 2014 S. Ferreira et al. [ ] | Packaging waste including (PS, PE, PET, mixed plastics) | 32,645 tonnes | CML 2001, ReCiPe | GWP, ETP, AD, EP, HT, POP, renewable and non-renewable energy |

| 2014 L. Rigamonti et al. [ ] | PET, HDPE, LDPE | 1000 tonnes per annum | CML 2001 | GWP, ETP, AP, POP |

| 2015 P.A. Wäger, R. Hischier [ ] | Mixed, plastic-rich residues from WEEE treatment | 1 tonne | ReCiPe | GWP, ETP (marine, freshwater and terrestrial), AP, FDP, EP, HT, POP, ODP |

| 2017 F. Gu et al. [ ] | Recycled plastic mainly PP and PE | 1 tonne | ReCiPe | GWP, ETP (marine, freshwater and terrestrial), AD, AP, FDP, EP, HT, POP, ODP, PMFP, ecosystem diversity (ED) |

| 2018 P. Hou et al. [ ] | Plastic film waste, mixed waste | 1 tonne | TRACI | GWP, AP, AD, FDP, EP, HT, ODP, habitat alteration, water intake, Indoor air quality |

| 2019 Y. Aryan et al. [ ] | PET, PE | 1 tonne | CML 2001 | GWP, ETP (marine, freshwater and terrestrial), AP, AD, FDP, EP, HT, POP, ODP |

| 2019 G. Faraca et al. [ ] | Post-consumer hard plastic (films and PVC) | 1 tonne | Undefined | GWP, ETP (terrestrial), AP, HT (cancer, non-cancer), POP, ODP, PMFP |

| 2019 H.H. Khoo [ ] | Plastic waste | 822,200 tonnes | ReCiPe | GWP, AP, PMFP |

| 2019 Y. Chen et al. [ ] | PP, PE, PVC, acrylonitrile-butadiene-styrene (ABS), PS, PET | 1 tonne | ReCiPe | GWP, ETP (marine, freshwater and terrestrial), AP, FDP, EP, HT, POP, ORP, PMFP, WDP (water depletion potential) |

| Publication | Start-Process | Intermediate Processes | End Products/Process |

|---|---|---|---|

| 2010 T. Chilton et al. [ ] | Post-consumer collection | PET recycling, transport of the PET granules, chemical/physical treatment, transport to the bottle manufacturing plant | Manufacture recycled bottles Landfill of discarded products |

| 2012 C.-E. Komly et al. [ ] | Raw fossil material | Production of PET bottles, recycling, incineration, landfill, possibility of multiple recycling trips included | Recycled product, landfill or incineration |

| 2012 M. Al-Maaded et al. [ ] | n/a | n/a | n/a |

| 2012 Nishijima et al. [ ] | Post-consumer collection (curbside collection and at retail points | Mechanical and feedstock recycling and incineration, energy recovery. Recovered materials and energy generated are subtracted from the system | Recycled product, landfill or incineration |

| 2013 S Rajendran et al. [ ] | Post-consumer collection | Recycling and WTE processes, including the transport of the residues, were included within the boundary | Recycled product, landfill or incineration |

| 2014 S.M. Al-Salem et al. [ ] | Sorting | MRF and two thermochemical treatments, VCC, and LTP. | Recycled product, landfill or incineration |

| 2014 S. Ferreira et al. [ ] | Sorting | Waste management processes by a Portuguese local authority including recycling of plastics. Comparison to landfill and recycling scenarios | Recycled product, landfill or incineration |

| 2014 L. Rigamonti et al. [ ] | Post-consumer collection | Recycling processes, waste-to-energy, and mechanical/biological treatments of the residuals | Recycled product, landfill or incineration |

| 2015 P.A. Wäger, R. Hischier [ ] | Stage 1: WEEE treatment output | Stage 1: transportation and recycling or incineration of plastic-rich materials resulting from WEEE processing | End products: heat and power, fuel for clinker production; plastic (mix); metals |

| Stage 2: WEEE treatment | Stage 2: transport of the plastic-rich residues to recycling facility, production of PCR plastics. Comparison to virgin plastic production | ||

| 2017 F. Gu et al. [ ] | Post-consumer collection | Defined by company processes for sorting, recycling, and production of materials and energy. | Recycled product, landfill or incineration |

| 2018 P. Hou et al. [ ] | Post-consumer collection (curbside and consumer drop-off) | Various end-of-life routes of plastic films included. Energy and recycled plastics generated are allocated as negative outputs of the system, indicating the reduction of resource use. | Recycled product, landfill or incineration |

| 2019 Y. Aryan et al. [ ] | Post-consumer collection | Waste treatment processes—landfilling, incineration, and recycling of PE and PET. Comparison to virgin PE/PET production | Recycled product, landfill or incineration |

| 2019 G. Faraca et al. [ ] | Sorting | All MSF processes but excludes waste collection | Recycled product, landfill or incineration |

| 2019 H.H. Khoo [ ] | Post-consumer collection | System boundaries are not explicitly stated in their report, but it can be inferred that all processes from collection to energy generation and landfill are included. | Transportation to mainland landfill by barge from Singapore City |

| 2019 Y. Chen et al. [ ] | Sorting | Cleaning and sorting, transport to landfill, incinerator, or recycling facility, and processing accordingly. Collection of wastes is excluded | Recycled product, landfill, or incineration |

| Impact Category | Reference | Location | MRF | WTE | Landfill |

|---|---|---|---|---|---|

| GWP | Al-Salem et al. (2014) | UK | −12 | 72 | 16 |

| Aryan et al. (2019) | India | 11 | 51 | 38 | |

| Chen et al. (2019) | China | −165 | 59 | 6 | |

| Ferreira et al. (2014) | Portugal | −1 | 99 | 0 | |

| AP | Al-Salem et al. (2014) | UK | −43 | −52 | 2 |

| Aryan et al. (2019) | India | 17 | 22 | 61 | |

| Chen et al. (2019) | China | −83 | −20 | 3 | |

| Ferreira et al. (2014) | Portugal | −56 | −29 | 15 |

| MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

Share and Cite

Alhazmi, H.; Almansour, F.H.; Aldhafeeri, Z. Plastic Waste Management: A Review of Existing Life Cycle Assessment Studies. Sustainability 2021 , 13 , 5340. https://doi.org/10.3390/su13105340

Alhazmi H, Almansour FH, Aldhafeeri Z. Plastic Waste Management: A Review of Existing Life Cycle Assessment Studies. Sustainability . 2021; 13(10):5340. https://doi.org/10.3390/su13105340

Alhazmi, Hatem, Faris H. Almansour, and Zaid Aldhafeeri. 2021. "Plastic Waste Management: A Review of Existing Life Cycle Assessment Studies" Sustainability 13, no. 10: 5340. https://doi.org/10.3390/su13105340

Article Metrics

Article access statistics, further information, mdpi initiatives, follow mdpi.

Subscribe to receive issue release notifications and newsletters from MDPI journals

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Philos Trans R Soc Lond B Biol Sci

- v.364(1526); 2009 Jul 27

Plastics, the environment and human health: current consensus and future trends

Richard c. thompson.

1 Marine Biology and Ecology Research Centre, Marine Institute, University of Plymouth, Drake Circus, Plymouth PL4 8AA, UK

Charles J. Moore

2 Algalita Marine Research Foundation, Long Beach, CA 90803, USA

Frederick S. vom Saal

3 Division of Biological Sciences, University of Missouri, Columbia, MO 65201, USA

Shanna H. Swan

4 Department of Obstetrics and Gynecology, University of Rochester, Rochester, NY 14642, USA

Plastics have transformed everyday life; usage is increasing and annual production is likely to exceed 300 million tonnes by 2010. In this concluding paper to the Theme Issue on Plastics, the Environment and Human Health, we synthesize current understanding of the benefits and concerns surrounding the use of plastics and look to future priorities, challenges and opportunities. It is evident that plastics bring many societal benefits and offer future technological and medical advances. However, concerns about usage and disposal are diverse and include accumulation of waste in landfills and in natural habitats, physical problems for wildlife resulting from ingestion or entanglement in plastic, the leaching of chemicals from plastic products and the potential for plastics to transfer chemicals to wildlife and humans. However, perhaps the most important overriding concern, which is implicit throughout this volume, is that our current usage is not sustainable. Around 4 per cent of world oil production is used as a feedstock to make plastics and a similar amount is used as energy in the process. Yet over a third of current production is used to make items of packaging, which are then rapidly discarded. Given our declining reserves of fossil fuels, and finite capacity for disposal of waste to landfill, this linear use of hydrocarbons, via packaging and other short-lived applications of plastic, is simply not sustainable. There are solutions, including material reduction, design for end-of-life recyclability, increased recycling capacity, development of bio-based feedstocks, strategies to reduce littering, the application of green chemistry life-cycle analyses and revised risk assessment approaches. Such measures will be most effective through the combined actions of the public, industry, scientists and policymakers. There is some urgency, as the quantity of plastics produced in the first 10 years of the current century is likely to approach the quantity produced in the entire century that preceded.

1. Introduction

Many of the current applications and the predicted benefits of plastic follow those outlined by Yarsley and Couzens in the 1940s. Their account of the benefits that plastics would bring to a person born nearly 70 years ago, at the beginning of this ‘ plastic age ’, was told with much optimism:

It is a world free from moth and rust and full of colour, a world largely built up of synthetic materials made from the most universally distributed substances, a world in which nations are more and more independent of localised naturalised resources, a world in which man, like a magician, makes what he wants for almost every need out of what is beneath and around him ( Yarsley & Couzens 1945 , p. 152).

The durability of plastics and their potential for diverse applications, including widespread use as disposable items, were anticipated, but the problems associated with waste management and plastic debris were not. In fact the predictions were ‘ how much brighter and cleaner a world [it would be] than that which preceded this plastic age ’ ( Yarsley & Couzens 1945 , p. 152).

This paper synthesizes current understanding of the benefits and concerns surrounding the use of plastics and looks to challenges, opportunities and priorities for the future. The content draws upon papers submitted to this Theme Issue on Plastics, the Environment and Human Health together with other sources. While selected citations are given to original sources of information, we primarily refer the reader to the discussion of a particular topic, and the associated references, in the Theme Issue papers. Here, we consider the subject from seven perspectives: plastics as materials; accumulation of plastic waste in the natural environment; effects of plastic debris in the environment and on wildlife; effects on humans; production, usage, disposal and waste management solutions; biopolymers, degradable and biodegradable polymer solutions; and policy measures.

2. Plastics as materials: an overview

Plastics are inexpensive, lightweight, strong, durable, corrosion-resistant materials, with high thermal and electrical insulation properties. The diversity of polymers and the versatility of their properties are used to make a vast array of products that bring medical and technological advances, energy savings and numerous other societal benefits ( Andrady & Neal 2009 ). As a consequence, the production of plastics has increased substantially over the last 60 years from around 0.5 million tonnes in 1950 to over 260 million tonnes today. In Europe alone the plastics industry has a turnover in excess of 300 million euros and employs 1.6 million people ( Plastics Europe 2008 ). Almost all aspects of daily life involve plastics, in transport, telecommunications, clothing, footwear and as packaging materials that facilitate the transport of a wide range of food, drink and other goods. There is considerable potential for new applications of plastics that will bring benefits in the future, for example as novel medical applications, in the generation of renewable energy and by reducing energy used in transport ( Andrady & Neal 2009 ).

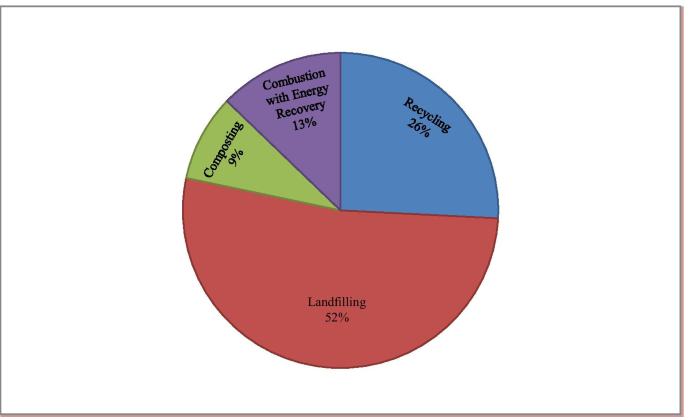

Virgin plastic polymers are rarely used by themselves and typically the polymer resins are mixed with various additives to improve performance. These additives include inorganic fillers such as carbon and silica that reinforce the material, plasticizers to render the material pliable, thermal and ultraviolet stabilizers, flame retardants and colourings. Many such additives are used in substantial quantities and in a wide range of products ( Meeker et al. 2009 ). Some additive chemicals are potentially toxic (for example lead and tributyl tin in polyvinyl chloride, PVC), but there is considerable controversy about the extent to which additives released from plastic products (such as phthalates and bisphenol A, BPA) have adverse effects in animal or human populations. The central issue here is relating the types and quantities of additives present in plastics to uptake and accumulation by living organisms ( Andrady & Neal 2009 ; Koch & Calafat 2009 ; Meeker et al. 2009 ; Oehlmann et al. 2009 ; Talsness et al. 2009 ; Wagner & Oehlmann 2009 ). Additives of particular concern are phthalate plasticizers, BPA, brominated flame retardants and anti-microbial agents. BPA and phthalates are found in many mass produced products including medical devices, food packaging, perfumes, cosmetics, toys, flooring materials, computers and CDs and can represent a significant content of the plastic. For instance, phthalates can constitute a substantial proportion, by weight, of PVC ( Oehlmann et al. 2009 ), while BPA is the monomer used for production of polycarbonate plastics as well as an additive used for production of PVC. Phthalates can leach out of products because they are not chemically bound to the plastic matrix, and they have attracted particular attention because of their high production volumes and wide usage ( Wagner & Oehlmann 2009 ; Talsness et al. 2009 ). Phthalates and BPA are detectable in aquatic environments, in dust and, because of their volatility, in air ( Rudel et al. 2001 , 2003 ). There is considerable concern about the adverse effects of these chemicals on wildlife and humans ( Meeker et al. 2009 ; Oehlmann et al. 2009 ). In addition to the reliance on finite resources for plastic production, and concerns about additive effects of different chemicals, current patterns of usage are generating global waste management problems. Barnes et al. (2009) show that plastic wastes, including packaging, electrical equipment and plastics from end-of-life vehicles, are major components of both household and industrial wastes; our capacity for disposal of waste to landfill is finite and in some locations landfills are at, or are rapidly approaching, capacity ( Defra et al. 2006 ). So from several perspectives it would seem that our current use and disposal of plastics is the cause for concern ( Barnes et al. 2009 ; Hopewell et al. 2009 ).

3. Accumulation of plastic waste in the natural environment

Substantial quantities of plastic have accumulated in the natural environment and in landfills. Around 10 per cent by weight of the municipal waste stream is plastic ( Barnes et al. 2009 ) and this will be considered later in §6 . Discarded plastic also contaminates a wide range of natural terrestrial, freshwater and marine habitats, with newspaper accounts of plastic debris on even some of the highest mountains. There are also some data on littering in the urban environment (for example compiled by EnCams in the UK; http://www.encams.org/home ); however, by comparison with the marine environment, there is a distinct lack of data on the accumulation of plastic debris in natural terrestrial and freshwater habitats. There are accounts of inadvertent contamination of soils with small plastic fragments as a consequence of spreading sewage sludge ( Zubris & Richards 2005 ), of fragments of plastic and glass contaminating compost prepared from municipal solid waste ( Brinton 2005 ) and of plastic being carried into streams, rivers and ultimately the sea with rain water and flood events ( Thompson et al. 2005 ). However, there is a clear need for more research on the quantities and effects of plastic debris in natural terrestrial habitats, on agricultural land and in freshwaters. Inevitably, therefore, much of the evidence presented here is from the marine environment. From the first accounts of plastic in the environment, which were reported from the carcasses of seabirds collected from shorelines in the early 1960s ( Harper & Fowler 1987 ), the extent of the problem soon became unmistakable with plastic debris contaminating oceans from the poles to the Equator and from shorelines to the deep sea. Most polymers are buoyant in water, and since items of plastic debris such as cartons and bottles often trap air, substantial quantities of plastic debris accumulate on the sea surface and may also be washed ashore. As a consequence, plastics represent a considerable proportion (50–80%) of shoreline debris ( Barnes et al. 2009 ). Quantities are highly variable in time and space, but there are reports of more than 100 000 items m –2 on some shorelines ( Gregory 1978 ) and up to 3 520 000 items km –2 at the ocean surface ( Yamashita & Tanimura 2007 ). Gyres and oceanic convergences appear to be particularly contaminated, as do enclosed seas such as the Mediterranean ( Barnes et al. 2009 ; Ryan et al. 2009 ). Despite their buoyant nature, plastics can become fouled with marine life and sediment causing items to sink to the seabed. For example, shallow seabeds in Brazil were more heavily contaminated than the neighbouring shorelines ( Oigman-Pszczol & Creed 2007 ), indicating that the seabed may be an ultimate sink even for initially buoyant marine debris ( Barnes et al. 2009 ). In some locations around Europe, it has been suggested that quantities on the seabed may exceed 10 000 items ha –1 , and debris has even been reported more than a 1000 m below the ocean surface, including accounts of inverted plastic bags passing a deep-sea submersible like an assembly of ghosts ( Gregory 2009 ). Quantitative data on the abundance of debris on the seabed are still very limited, but there are concerns that degradation rates in the deep sea will be especially slow because of darkness and cold ( Barnes et al. 2009 ; Ryan et al. 2009 ).

Monitoring the abundance of debris is important to establish rates of accumulation and the effectiveness of any remediation measures. Most studies assess the abundance of all types of anthropogenic debris including data on plastics and/or plastic items as a category. In general, the abundance of debris on shorelines has been extensively monitored, in comparison to surveys from the open oceans or the seabed. In addition to recording debris, there is a need to collect data on sources; for plastic debris this should include discharges from rivers and sewers together with littering behaviour. Here, the limited data we have suggest that storm water pulses provide a major pathway for debris from the land to the sea, with 81 g m –3 of plastic debris during high-flow events in the USA ( Ryan et al. 2009 ). Methods to monitor the abundance of anthropogenic debris (including plastics) often vary considerably between countries and organizations, adding to difficulties in interpreting trends. As a consequence, the United Nations Environment Programme and the OSPAR Commission are currently taking steps to introduce standardized protocols ( OSPAR 2007 ; Cheshire et al. 2009 ). Some trends are evident, however, typically with an increase in the abundance of debris and fragments between the 1960s and the 1990s ( Barnes et al. 2009 ). More recently, abundance at the sea surface in some regions and on some shorelines appears to be stabilizing, while in other areas such as the Pacific Gyre there are reports of considerable increases. On shorelines the quantities of debris, predominantly plastic, are greater in the Northern than in the Southern Hemisphere ( Barnes 2005 ). The abundance of debris is greater adjacent to urban centres and on more frequented beaches and there is evidence that plastics are accumulating and becoming buried in sediments ( Barnes et al. 2009 ; Ryan et al. 2009 ). Barnes et al. (2009) consider that contamination of remote habitats, such as the deep sea and the polar regions, is likely to increase as debris is carried there from more densely populated areas. Allowing for variability between habitats and locations, it seems inevitable, however, that the quantity of debris in the environment as a whole will continue to increase—unless we all change our practices. Even with such changes, plastic debris that is already in the environment will persist for a considerable time to come. The persistence of plastic debris and the associated environmental hazards are illustrated poignantly by Barnes et al. (2009) who describe debris that had originated from an aeroplane being ingested by an albatross some 60 years after the plane had crashed.

4. Effects of plastic debris in the environment and on wildlife

There are some accounts of effects of debris from terrestrial habitats, for example ingestion by the endangered California condor, Gymnogyps californianus ( Mee et al. 2007 ). However, the vast majority of work describing environmental consequences of plastic debris is from marine settings and more work on terrestrial and freshwater habitats is needed. Plastic debris causes aesthetic problems, and it also presents a hazard to maritime activities including fishing and tourism ( Moore 2008 ; Gregory 2009 ). Discarded fishing nets result in ghost fishing that may result in losses to commercial fisheries ( Moore 2008 ; Brown & Macfadyen 2007 ). Floating plastic debris can rapidly become colonized by marine organisms and since it can persist at the sea surface for substantial periods, it may subsequently facilitate the transport of non-native or ‘alien’ species ( Barnes 2002 ; Barnes et al. 2009 ; Gregory 2009 ). However, the problems attracting most public and media attention are those resulting in ingestion and entanglement by wildlife. Over 260 species, including invertebrates, turtles, fish, seabirds and mammals, have been reported to ingest or become entangled in plastic debris, resulting in impaired movement and feeding, reduced reproductive output, lacerations, ulcers and death ( Laist 1997 ; Derraik 2002 ; Gregory 2009 ). The limited monitoring data we have suggest rates of entanglement have increased over time ( Ryan et al. 2009 ). A wide range of species with different modes of feeding including filter feeders, deposit feeders and detritivores are known to ingest plastics. However, ingestion is likely to be particularly problematic for species that specifically select plastic items because they mistake them for their food. As a consequence, the incidence of ingestion can be extremely high in some populations. For example, 95 per cent of fulmars washed ashore dead in the North Sea have plastic in their guts, with substantial quantities of plastic being reported in the guts of other birds, including albatross and prions ( Gregory 2009 ). There are some very good data on the quantity of debris ingested by seabirds recorded from the carcasses of dead birds. This approach has been used to monitor temporal and spatial patterns in the abundance of sea-surface plastic debris on regional scales around Europe ( Van Franeker et al. 2005 ; Ryan et al. 2009 ).

An area of particular concern is the abundance of small plastic fragments or microplastics. Fragments as small as 1.6 µm have been identified in some marine habitats, and it seems likely there will be even smaller pieces below current levels of detection. A recent workshop convened in the USA by the National Oceanic and Atmospheric Administration concluded that microplastics be defined as pieces <5 mm with a suggested lower size boundary of 333 µm so as to focus on microplastics that will be captured using conventional sampling approaches ( Arthur et al. 2009 ). However, we consider it important that the abundance of even smaller fragments is not neglected. Plastic fragments appear to form by the mechanical and chemical deterioration of larger items. Alternative routes for microplastics to enter the environment include the direct release of small pieces of plastics that are used as abrasives in industrial and domestic cleaning applications (e.g. shot blasting or scrubbers used in proprietary hand cleansers) and spillage of plastic pellets and powders that are used as a feedstock for the manufacture of most plastic products. Data from shorelines, from the open ocean and from debris ingested by seabirds, all indicate that quantities of plastic fragments are increasing in the environment, and quantities on some shores are substantial (>10% by weight of strandline material; Barnes et al. 2009 ). Laboratory experiments have shown that small pieces such as these can be ingested by small marine invertebrates including filter feeders, deposit feeders and detritivores ( Thompson et al. 2004 ), while mussels were shown to retain plastic for over 48 days ( Browne et al. 2008 ). However, the extent and consequences of ingestion of microplastics by natural populations are not known.

In addition to the physical problems associated with plastic debris, there has been much speculation that, if ingested, plastic has the potential to transfer toxic substances to the food chain (see Teuten et al. 2009 ). In the marine environment, plastic debris such as pellets, fragments and microplastics have been shown to contain organic contaminants including polychlorinated biphenyls (PCBs), polycyclic aromatic hydrocarbons, petroleum hydrocarbons, organochlorine pesticides (2,2′-bis( p -chlorophenyl)-1,1,1 trichloroethane (DDT) and its metabolites; together with hexachlorinated hexane (HCH)), polybrominated diphenylethers (PBDEs), alkylphenols and BPA at concentrations ranging from ng g –1 to µg g –1 . Some of these compounds are added to plastics during manufacture while others adsorb to plastic debris from the environment. Work in Japan has shown that plastics can accumulate and concentrate persistent organic pollutants that have arisen in the environment from other sources. These contaminants can become orders of magnitude more concentrated on the surface of plastic debris than in the surrounding sea water ( Mato et al. 2001 ). Teuten et al. (2009) describe experiments to examine the transfer of these contaminants from plastics to seabirds and other animals. The potential for transport varies among contaminants, polymers and possibly also according to the state of environmental weathering of the debris. Recent mathematical modelling studies have shown that even very small quantities of plastics could facilitate transport of contaminants from plastic to organisms upon ingestion. This could present a direct and important route for the transport of chemicals to higher animals such as seabirds ( Teuten et al. 2007 , 2009 ), but will depend upon the nature of the habitat and the amount and type of plastics present. For instance, the extent to which the presence of plastic particles might contribute to the total burden of contaminants transferred from the environment to organisms will depend upon competitive sorption and transport by other particulates ( Arthur et al. 2009 ). The abundance of fragments of plastic is increasing in the environment; these particles, especially truly microscopic fragments less than the 333 µm proposed by NOAA (see earlier), have a relatively large surface area to volume ratio that is likely to facilitate the transport of contaminants, and because of their size such fragments can be ingested by a wide range of organisms. Hence, the potential for plastics to transport and release chemicals to wildlife is an emerging area of concern.

More work will be needed to establish the full environmental relevance of plastics in the transport of contaminants to organisms living in the natural environment, and the extent to which these chemicals could then be transported along food chains. However, there is already clear evidence that chemicals associated with plastic are potentially harmful to wildlife. Data that have principally been collected using laboratory exposures are summarized by Oehlmann et al. (2009) . These show that phthalates and BPA affect reproduction in all studied animal groups and impair development in crustaceans and amphibians. Molluscs and amphibians appear to be particularly sensitive to these compounds and biological effects have been observed in the low ng l –1 to µg l –1 range. In contrast, most effects in fish tend to occur at higher concentrations. Most plasticizers appear to act by interfering with hormone function, although they can do this by several mechanisms ( Hu et al. 2009 ). Effects observed in the laboratory coincide with measured environmental concentrations, thus there is a very real probability that these chemicals are affecting natural populations ( Oehlmann et al. 2009 ). BPA concentrations in aquatic environments vary considerably, but can reach 21 µg l –1 in freshwater systems and concentrations in sediments are generally several orders of magnitude higher than in the water column. For example, in the River Elbe, Germany, BPA was measured at 0.77 µg l –1 in water compared with 343 µg kg –1 in sediment (dry weight). These findings are in stark contrast with the European Union environmental risk assessment predicted environmental concentrations of 0.12 µg l –1 for water and 1.6 µg kg –1 (dry weight) for sediments.

Phthalates and BPA can bioaccumulate in organisms, but there is much variability between species and individuals according to the type of plasticizer and experimental protocol. However, concentration factors are generally higher for invertebrates than vertebrates, and can be especially high in some species of molluscs and crustaceans. While there is clear evidence that these chemicals have adverse effects at environmentally relevant concentrations in laboratory studies, there is a need for further research to establish population-level effects in the natural environment (see discussion in Oehlmann et al. 2009 ), to establish the long-term effects of exposures (particularly due to exposure of embryos), to determine effects of exposure to contaminant mixtures and to establish the role of plastics as sources (albeit not exclusive sources) of these contaminants (see Meeker et al. (2009) for discussion of sources and routes of exposure).

5. Effects on humans: epidemiological and experimental evidence

Turning to adverse effects of plastic on the human population, there is a growing body of literature on potential health risks. A range of chemicals that are used in the manufacture of plastics are known to be toxic. Biomonitoring (e.g. measuring concentration of environmental contaminants in human tissue) provides an integrated measure of an organism's exposure to contaminants from multiple sources. This approach has shown that chemicals used in the manufacture of plastics are present in the human population, and studies using laboratory animals as model organisms indicate potential adverse health effects of these chemicals ( Talsness et al. 2009 ). Body burdens of chemicals that are used in plastic manufacture have also been correlated with adverse effects in the human population, including reproductive abnormalities (e.g. Swan et al. 2005 ; Swan 2008 ; Lang et al. 2008 ).

Interpreting biomonitoring data is complex, and a key task is to set information into perspective with dose levels that are considered toxic on the basis of experimental studies in laboratory animals. The concept of ‘toxicity’ and thus the experimental methods for studying the health impacts of the chemicals in plastic, and other chemicals classified as endocrine disruptors, is currently undergoing a transformation (a paradigm inversion) since the disruption of endocrine regulatory systems requires approaches very different from the study of acute toxicants or poisons. There is thus extensive evidence that traditional toxicological approaches are inadequate for revealing outcomes such as ‘reprogramming’ of the molecular systems in cells as a result of exposure to very low doses during critical periods in development (e.g. Myers et al. 2009 ). Research on experimental animals informs epidemiologists about the potential for adverse effects in humans and thus plays a critical role in chemical risk assessments. A key conclusion from the paper by Talsness et al. (2009) is the need to modify our approach to chemical testing for risk assessment. As noted by these authors and others, there is a need to integrate concepts of endocrinology in the assumptions underlying chemical risk assessment. In particular, the assumptions that dose–response curves are monotonic and that there are threshold doses (safe levels) are not true for either endogenous hormones or for chemicals with hormonal activity (which includes many chemicals used in plastics) ( Talsness et al. 2009) .

The biomonitoring approach has demonstrated phthalates and BPA, as well as other additives in plastics and their metabolites, are present in the human population. It has also demonstrated that the most common human exposure scenario is to a large number of these chemicals simultaneously. These data indicate differences according to geographical location and age, with greater concentrations of some of these chemicals in young children. While exposure via house dust is extensive ( Rudel et al. 2008 ), it would appear that at least for some phthalates (e.g. diethylhexyl phthalate, DEHP), foodstuffs and to a lesser extent use of oral drugs probably present major uptake pathways ( Wormuth et al. 2006 ). Exposure data for BPA are similar but less extensive. While average concentrations of phthalates in selected populations worldwide appear quite similar, there is evidence of considerable variability in daily intake rates among individuals, and even within individuals ( Peck et al. 2009 ). Exposures through ingestion, inhalation and dermal contact are all considered important routes of exposure for the general population ( Adibi et al. 2003 ; Rudel et al. 2003 ). Koch & Calafat (2009 ) show that while mean/median exposures for the general population were below levels determined to be safe for daily exposure (USA, EPA reference dose, RfD; and European Union tolerable daily intake, TDI), the upper percentiles of di-butyl phthalate and DEHP urinary metabolite concentrations show that for some people daily intake might be substantially higher than previously assumed and could exceed estimated safe daily exposure levels. Current ‘safe’ exposure levels are typically based on the application of traditional toxicological assumptions regarding acute toxicants to calculate daily exposures for chemicals in a range of widely used plastic items. The toxicological consequences of such exposures, especially for susceptible subpopulations such as children and pregnant women, remain unclear and warrant further investigation. However, there is evidence of associations between urinary concentrations of some phthalate metabolites and biological outcomes ( Swan et al. 2005 ; Swan 2008 ). For example, an inverse relationship has been reported between the concentrations of DEHP metabolites in the mother's urine and anogenital distance, penile width and testicular decent in male offspring ( Swan et al. 2005 ; Swan 2008 ). In adults, there is some evidence of a negative association between phthalate metabolites and semen quality (Meeker & Sathyanarayana) and between high exposures to phthalates (workers producing PVC flooring) and free testosterone levels. Moreover, recent work ( Lang et al. 2008 ) has shown a significant relationship between urine levels of BPA and cardiovascular disease, type 2 diabetes and abnormalities in liver enzymes, and Stahlhut et al. (2009) have reported that exposure of adults in the USA to BPA is likely to occur from multiple sources and that the half-life of BPA is longer than previously estimated, and the very high exposure of premature infants in neonatal intensive-care units to both BPA and phthalates is of great concern ( Calafat et al. 2009 ). These data indicate detrimental effects in the general population may be caused by chronic low-dose exposures (separately or in combination) and acute exposure to higher doses, but the full extent to which chemicals are transported to the human population by plastics is yet to be confirmed.

Much has been learned about toxicological effects on humans from experiments using laboratory animals. This approach has been used to examine component chemicals used in plastic production. A summary of work on phthalates, BPA and tetrabromobisphenol A (TBBPA) is presented by Talsness et al. (2009) . The male reproductive tract is particularly sensitive to phthalate exposure. However, most reproductive effects are not exerted by phthalate diesters themselves, but by their monoester metabolites, which are formed in the liver. The majority of these studies have been done using rats as a model organism, with doses at least an order of magnitude higher than those to which humans are commonly exposed, but they have resulted in rapid, severe changes in the rat testis. Reproductive effects have also been described in mice and guinea pigs. Effects on pre- and early post-natal development are of particular concern, and recent animal studies have shown exposures to certain phthalates can result in severe disorders of the developing male reproductive system. It should be noted that most work on animals has used phthalate exposures much higher than estimated daily human exposures (see above), and researchers have only recently started to investigate possible biological effects within the range of median human phthalate exposure ( Talsness et al. 2009 ). This is of critical importance because epidemiological studies have reported associations between phthalate levels and a number of adverse health effects in humans ( Swan et al. 2005 ), suggesting that either humans are more sensitive to phthalates than experimental animals or that the testing paradigm used in traditional toxicological studies, which examines one phthalate at a time, has not served to accurately predict adverse effects from the mixture of phthalates to which humans are exposed ( Andrade et al. 2006 ; NAS 2008 ).

For BPA, there is an extensive published literature showing adverse effects of exposure at very low doses, based on administration during development and to adult experimental animals. In particular, unlike the case for experimental animal research on phthalates, there are now hundreds of experiments on laboratory animals using doses within the range of human exposures ( Vandenberg et al. 2007 ). The rate and extent to which BPA is metabolized affect the interpretation of these findings, but even very low doses of BPA have been shown to cause significant stimulation of insulin secretion followed by insulin resistance in mice, a significant decrease in sperm production by rats, a decrease in maternal behaviour in mice and disruption of hippocampal synapses, leading to the appearance of a brain typical of that seen in senility in both rats and monkeys. The greatest concerns with exposure to BPA are during development; BPA appears to affect brain development leading to loss of sex differentiation in brain structures and behaviour ( Talsness et al. 2009 ). A further important observation regarding adverse responses to developmental exposures of animals to very low doses of BPA is that many relate to disease trends in humans. Less has been published on effects of the flame retardant TBBPA, but there is evidence of effects on thyroid hormones, pituitary function and reproductive success in animals ( Talsness et al. 2009 ).

Despite the environmental concerns about some of the chemicals used in plastic manufacture, it is important to emphasize that evidence for effects in humans is still limited and there is a need for further research and in particular, for longitudinal studies to examine temporal relationships with chemicals that leach out of plastics ( Adibi et al. 2008 ). In addition, the traditional approach to studying the toxicity of chemicals has been to focus only on exposure to individual chemicals in relation to disease or abnormalities. However, because of the complex integrated nature of the endocrine system, it is critical that future studies involving endocrine-disrupting chemicals that leach from plastic products focus on mixtures of chemicals to which people are exposed when they use common household products. For example, in a study conducted in the USA, 80 per cent of babies were exposed to measurable levels of at least nine different phthalate metabolites ( Sathyanarayana et al. 2008 ), and the health impacts of the cumulative exposure to these chemicals need to be determined. An initial attempt at examining more than one phthalate as a contributor to abnormal genital development in babies has shown the importance of this approach ( Swan 2008 ). Studies of mixtures of chemicals therefore also need to extend beyond mixtures of the same class of chemical, such as mixtures of different phthalates or of different PCBs. For example, PVC (used in a wide range of products in the home including water pipes) may contain phthalates, BPA, flame retardants such as PBDEs or TBBPA, cadmium, lead and organotins, all of which have been shown in animal studies to result in obesity ( Heindel & vom Saal 2009 ). In addition, the monomer used to manufacture PVC plastic, vinyl chloride, is a known carcinogen and exposure can cause angiosarcoma of the liver among factory workers ( Bolt 2005 ; Gennaro et al. 2008 ). PVC in medical tubing has also been shown to be a source of high DEHP exposure among infants in neonatal intensive-care nurseries ( Green et al. 2005 ) and probably contributes to the high levels of BPA found in these babies since BPA is an additive in PVC plastic ( Calafat et al. 2009 ).

Examining the relationship between plastic additives and adverse human effects presents a number of challenges. In particular, the changing patterns of production and use of both plastics, and the additives they contain, as well as the confidential nature of industrial specifications makes exposure assessment particularly difficult. Evolving technology, methodology and statistical approaches should help disentangle the relationships between these chemicals and health effects. However, with most of the statistically significant hormone alternations that have been attributed to environmental and occupational exposures, the actual degree of hormone alteration has been considered subclinical. Hence, more information is required on the biological mechanisms that may be affected by plastic additives and in particular, low-dose chronic exposures. Meanwhile we should consider strategies to reduce the use of these chemicals in plastic manufacture and/or develop and test alternatives (for example citrates are being developed as substitute plasticizers). This is the goal of the new field of green chemistry, which is based on the premise that development of chemicals for use in commerce should involve an interaction between biologists and chemists. Had this approach been in place 50 years ago it would probably have prevented the development of chemicals that are recognized as likely endocrine disruptors ( Anastas & Beach 2007 ). There is also a need for industry and independent scientists to work more closely with, rather than against, each other in order to focus effectively on the best ways forward. For example, contrast comments on BPA by Bird (2005 ) with those of vom Saal (2005 ), and contrast comments in this volume on the safety of plastic additives by Andrady & Neal (2009 ) with those by Koch & Calafat (2009 ), Meeker et al. (2009 ), Oehlmann et al. (2009) and Talsness et al. (2009) .

6. Production, usage, disposal and waste management solutions