- Business Essentials

- Leadership & Management

- Credential of Leadership, Impact, and Management in Business (CLIMB)

- Entrepreneurship & Innovation

- Digital Transformation

- Finance & Accounting

- Business in Society

- For Organizations

- Support Portal

- Media Coverage

- Founding Donors

- Leadership Team

- Harvard Business School →

- HBS Online →

- Business Insights →

Business Insights

Harvard Business School Online's Business Insights Blog provides the career insights you need to achieve your goals and gain confidence in your business skills.

- Career Development

- Communication

- Decision-Making

- Earning Your MBA

- Negotiation

- News & Events

- Productivity

- Staff Spotlight

- Student Profiles

- Work-Life Balance

- AI Essentials for Business

- Alternative Investments

- Business Analytics

- Business Strategy

- Business and Climate Change

- Creating Brand Value

- Design Thinking and Innovation

- Digital Marketing Strategy

- Disruptive Strategy

- Economics for Managers

- Entrepreneurship Essentials

- Financial Accounting

- Global Business

- Launching Tech Ventures

- Leadership Principles

- Leadership, Ethics, and Corporate Accountability

- Leading Change and Organizational Renewal

- Leading with Finance

- Management Essentials

- Negotiation Mastery

- Organizational Leadership

- Power and Influence for Positive Impact

- Strategy Execution

- Sustainable Business Strategy

- Sustainable Investing

- Winning with Digital Platforms

Root Cause Analysis: What It Is & How to Perform One

- 07 Mar 2023

The problems that affect a company’s success don’t always result from not understanding how to solve them. In many cases, their root causes aren’t easily identified. That’s why root cause analysis is vital to organizational leadership .

According to research described in the Harvard Business Review , 85 percent of executives believe their organizations are bad at diagnosing problems, and 87 percent think that flaw carries significant costs. As a result, more businesses seek organizational leaders who avoid costly mistakes.

If you’re a leader who wants to problem-solve effectively, here’s an overview of root cause analysis and why it’s important in organizational leadership.

Access your free e-book today.

What Is Root Cause Analysis?

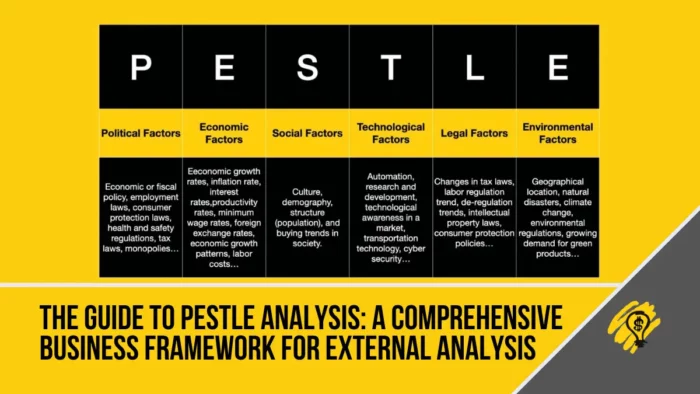

According to the online course Organizational Leadership —taught by Harvard Business School professors Joshua Margolis and Anthony Mayo— root cause analysis is the process of articulating problems’ causes to suggest specific solutions.

“Leaders must perform as beacons,” Margolis says in the course. “Namely, scanning and analyzing the landscape around the organization and identifying current and emerging trends, pressures, threats, and opportunities.”

By working with others to understand a problem’s root cause, you can generate a solution. If you’re interested in performing a root cause analysis for your organization, here are eight steps you must take.

8 Essential Steps of an Organizational Root Cause Analysis

1. identify performance or opportunity gaps.

The first step in a root cause analysis is identifying the most important performance or opportunity gaps facing your team, department, or organization. Performance gaps are the ways in which your organization falls short or fails to deliver on its capabilities; opportunity gaps reflect something new or innovative it can do to create value.

Finding those gaps requires leveraging the “leader as beacon” form of leadership.

“Leaders are called upon to illuminate what's going on outside and around the organization,” Margolis says in Organizational Leadership , “identifying both challenges and opportunities and how they inform the organization's future direction.”

Without those insights, you can’t reap the benefits an effective root cause analysis can produce because external forces—including industry trends, competitors, and the economy—can affect your company’s long-term success.

2. Create an Organizational Challenge Statement

The next step is writing an organizational challenge statement explaining what the gap is and why it’s important. The statement should be three to four sentences and encapsulate the challenge’s essence.

It’s crucial to explain where your organization falls short, what problems that poses, and why it matters. Describe the gap and why you must urgently address it.

A critical responsibility is deciding which gap requires the most attention, then focusing your analysis on it. Concentrating on too many problems at once can dilute positive results.

To prioritize issues, consider which are the most time-sensitive and mission-critical, followed by which can make stakeholders happy.

3. Analyze Findings with Colleagues

It's essential to work with colleagues to gain different perspectives on a problem and its root causes. This involves understanding the problem, gathering information, and developing a comprehensive analysis.

While this can be challenging when you’re a new organizational leader, using the double helix of leadership —the coevolutionary process of executing organizational leadership's responsibilities while developing the capabilities to perform them—can help foster collaboration.

Research shows diverse ideas improve high-level decision-making, which is why you should connect with colleagues with different opinions and expertise to enhance your root cause analysis’s outcome.

4. Formulate Value-Creating Activities

Next, determine what your company must do to address your organizational challenge statement. Establish three to five value-creating activities for your team, department, or organization to close the performance or opportunity gap you’ve identified.

This requires communicating organizational direction —a clear and compelling path forward that ensures stakeholders know and work toward the same goal.

“Setting direction is typically a reciprocal process,” Margolis says in Organizational Leadership . “You don't sit down and decide your direction, nor do you input your analysis of the external context into a formula and solve for a direction. Rather, setting direction is a back-and-forth process; you move between the value you'd like to create for customers, employees, investors, and your grasp of the context.”

5. Identify Necessary Behavior Changes

Once you’ve outlined activities that can provide value to your company, identify the behavior changes needed to address your organizational challenge statement.

“Your detective work throughout your root cause analysis exposes uncomfortable realities about employee competencies, organizational inefficiencies, departmental infighting, and unclear direction from leadership at multiple levels of the company,” Mayo says in Organizational Leadership .

Factors that can affect your company’s long-term success include:

- Ineffective communication skills

- Resistance to change

- Problematic workplace stereotypes

Not all root cause analyses reveal behaviors that must be eliminated. Sometimes you can identify behaviors to enhance or foster internally, such as:

- Collaboration

- Innovative thinking

- Creative problem-solving

6. Implement Behavior Changes

Although behaviors might be easy to pinpoint, putting them into practice can be challenging.

To ensure you implement the right changes, gauge whether they’ll have a positive or negative impact. According to Organizational Leadership , you should consider the following factors:

- Motivation: Do the people at your organization have a personal desire for and commitment to change?

- Competence: Do they have the skills and know-how to implement change effectively?

- Coordination: Are they willing to work collaboratively to enact change?

Based on your answers, decide what behavior changes are plausible for your root cause analysis.

7. Map Root Causes

The next step in your analysis is mapping the root causes you’ve identified to the components of organizational alignment. Doing so helps you determine which components to adjust or change to implement employee behavior changes successfully.

Three root cause categories unrelated to behavior changes are:

- Systems and structures: The formal organization component, including talent management, product development, and budget and accountability systems

- People: Individuals’ profiles and the workforce’s overall composition, including employees’ skills, experience, values, and attitudes

- Culture: The informal, intangible part of your organization, including the norms, values, attitudes, beliefs, preferences, common practices, and habits of its employees

8. Create an Action Plan

Using your findings from the previous steps, create an action plan for addressing your organizational problem’s root cause and consider your role in it.

To make the action plan achievable, ensure you:

- Identify the problem’s root cause

- Create measurable results

- Ensure clear communication among your team

“One useful way to assess your potential impact on the challenge is to understand your locus of control,” Mayo says in Organizational Leadership , “or the extent to which you can personally drive the needed change or improvement.”

The best way to illustrate your control is by using three concentric circles: the innermost circle being full control of resources, the middle circle representing your ability to influence but not control, and the outermost circle alluding to shifts outside both your influence and control.

Consider these circles when implementing your action plan to ensure your goals don’t overreach.

The Importance of Root Cause Analysis in Organizational Leadership

Root cause analysis is a critical organizational leadership skill for effectively addressing problems and driving change. It helps you understand shifting conditions around your company and confirm that your efforts are relevant and sustainable.

As a leader, you must not only effect change but understand why it’s needed. Taking an online course, such as Organizational Leadership , can enable you to gain that knowledge.

Using root cause analysis, you can identify the issues behind your organization’s problems, develop a plan to address them, and make impactful changes.

Are you preparing to transition to a new leadership role? Enroll in our online certificate course Organizational Leadership —one of our leadership and management courses —and learn how to perform an effective root cause analysis to ensure your company’s long-term success. To learn more about what it takes to be an effective leader, download our free leadership e-book .

About the Author

- Quality Management

Home » Free Resources » »

What is Root Cause Analysis? Process, Example & Everything You Need to Know

- Written by Contributing Writer

- Updated on March 7, 2023

Root cause analysis (RCA) is a problem-solving methodology used to identify the underlying cause of a problem, incident, or adverse event. Simply put, it is pinpointing the root of the problem to solve and prevent it from happening again.

When faced with a problem, we usually try to get to the bottom of it. For example, in the unfortunate event that we break our bones, we would be in immense pain. We might take measures to control the pain and blood loss. But our efforts don’t stop at simply having a painkiller and applying a bandage. We rush to the ER as soon as possible, get the necessary treatment to mend the broken bones, and make sure we are careful not to have such an accident.

What we did here is we analyzed the problem: the pain and took steps to fix the root cause, which is the broken bones. Here the pain is the symptom, and the fractured bone is the root cause.

Now that we are familiar with what it stands for let us dive deep into root cause analysis, or RCA, which is the systematic approach employed in various industries like healthcare, manufacturing, governmental organizations, aviation, etc. We also examine its definition, history, benefits, approaches, process, principles, tips, and how to learn more .

Defining RCA Analysis

Root cause analysis is a problem-solving process that seeks to identify the underlying cause of a problem or issue. It’s a systematic approach that goes beyond just identifying symptoms and aims to uncover the root cause of the problem. The objective is to prevent future occurrences of the situation by addressing its root cause.

RCA analysis involves collecting and analyzing data to identify a problem’s underlying cause. The process typically consists of a team of experts who use various tools and techniques to gather and analyze data. Once the root cause has been identified, the team develops a plan to address the root cause and prevent future occurrences of the problem.

Also Read: What Is Process Capability and Why It’s More Interesting Than It Sounds

History of Root Cause Analysis

The origins of root cause analysis can be traced back to the late 19th century when it was used in the manufacturing industry to improve production processes. In the 20th century, it was further developed and applied to a broader range of industries, including healthcare and aviation.

In the 1950s when manufacturers started to use it to understand industrial events. The primary goal of RCA is to determine the fundamental cause of a problem, which is referred to as the “root cause.”

One of the earliest adopters of RCA was Toyota, who employed the “5 whys” method, where the investigation of a breakdown or undesired event is conducted by asking “why” at least five times. This approach forces quality personnel to delve deeper and understand the underlying causes, layer by layer. Today, RCA is widely used in various industries to identify and eliminate problems, improve processes, and prevent recurrence.

RCA was first used in the healthcare industry to address adverse events and improve patient safety. The Institute of Healthcare Improvement (IHI) developed the RCA process in the late 1980s, and it quickly became a standard tool for improving patient safety and quality of care.

The Joint Commission, a US-based nonprofit that accredits healthcare organizations and programs, requires a root cause analysis (RCA) to be conducted whenever an accredited hospital experiences a specific type of adverse event. These are known as “sentinel” incidents, as they reveal a dangerous flaw in the care provided and prompt an immediate investigation and response.

RCA was developed in response to the growing number of plane crashes and incidents in the aviation industry. The National Transportation Safety Board (NTSB) was established in 1967. It has since been using RCA to investigate plane crashes and incidents to identify their root causes and prevent future occurrences.

Benefits of Root Cause Analysis

Before we go to explore how various industries and organizations benefit from implementing RCA, let us discuss the primary goals of root cause analysis.

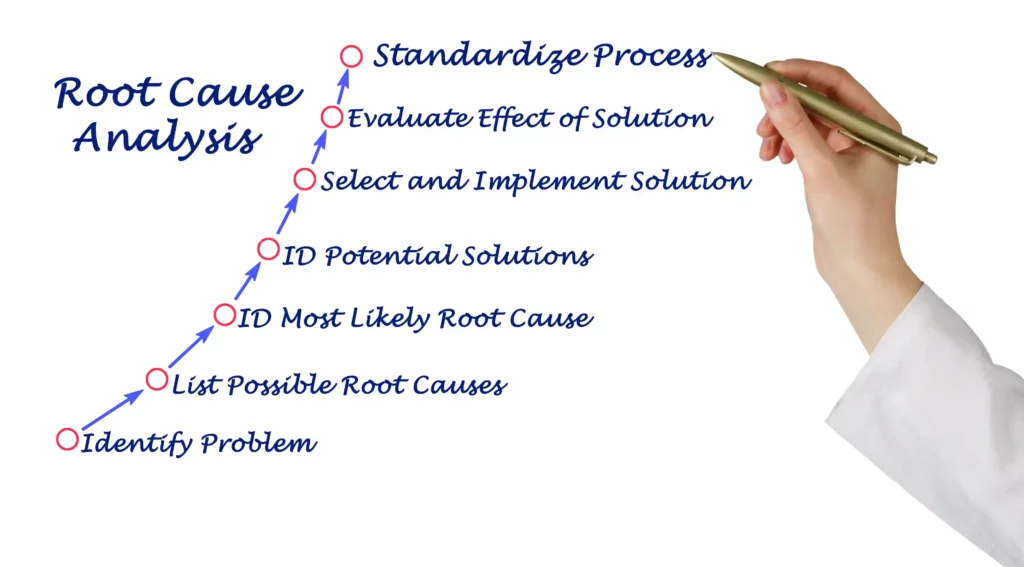

The three main goals of RCA are:

- Identifying the root cause: The first goal is to discover the primary source of the problem or event. This is essential to understand the underlying causes and find practical solutions.

- Understanding the issues: The second goal of RCA is to fully comprehend the nature of the issues and develop a plan to fix, compensate, or learn from them. This requires a comprehensive analysis of the root cause and the factors contributing to it.

- Applying learnings: The third goal of RCA is to use the information gained from the analysis to prevent similar problems from occurring in the future. This includes making systemic changes to processes and systems and implementing measures to mitigate the risk of future adverse events.

Root cause analysis offers numerous benefits to organizations and industries. Some of the key benefits include:

- Improving quality: RCA helps organizations identify the root cause of problems and implement solutions to prevent future occurrences, improving quality and efficiency.

- Reducing risk: Organizations can reduce the risk of future incidents and adverse events by identifying the root cause of the problem and hence improving overall safety and security.

- Enhancing customer satisfaction: Organizations can better manage their product issues by addressing the root cause of problems. Thus organizations can improve customer satisfaction and trust.

- Improving organizational learning : RCA provides organizations with a systematic process for learning from problems and incidents, enabling them to improve their processes and procedures continuously.

- Increasing efficiency and productivity: Organizations can improve their processes and procedures by addressing the root cause of problems, leading to increased efficiency and productivity.

Also Read: Demystifying the Theory of Constraints

Top Approaches of Root Cause Analysis

There are several approaches to root cause analysis, each with its unique methodology and tools. Let’s discuss some of the most commonly-used types of root cause analysis.

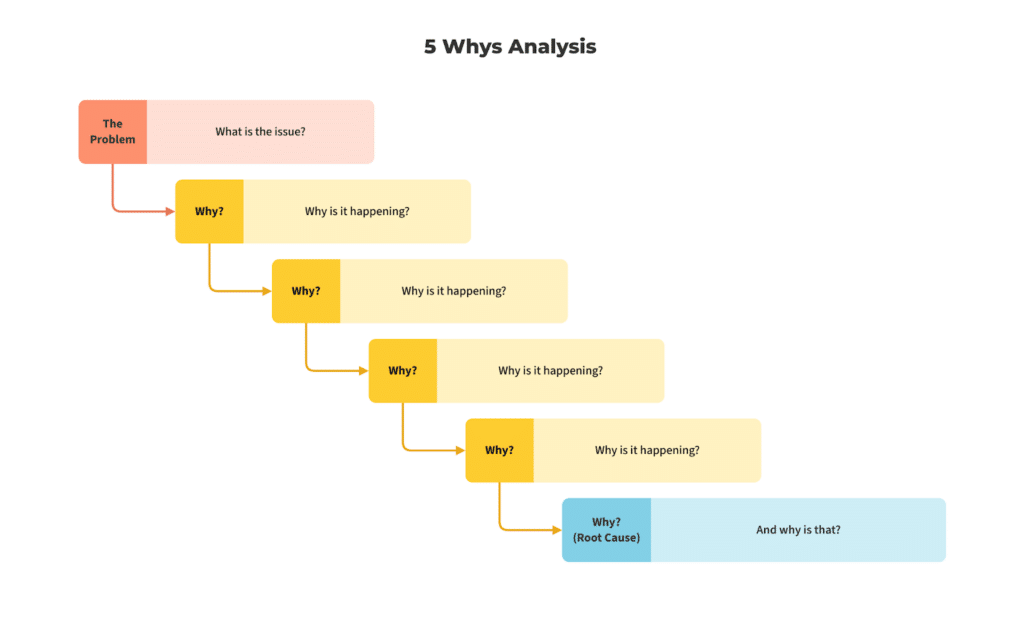

The 5 Whys Root Cause Analysis

The 5 Whys root cause analysis approach is beneficial for solving simple problems or identifying root causes in a short amount of time. This simple yet effective approach involves asking “why” questions to identify the root cause of a problem. The process is repeated until the root cause is identified. For example, in a service industry setting, in case of a complaint, by asking “why” five times, the team could drill down layer by layer to understand the underlying causes of the problem, such as poor communication, inadequate training, or poor service quality.

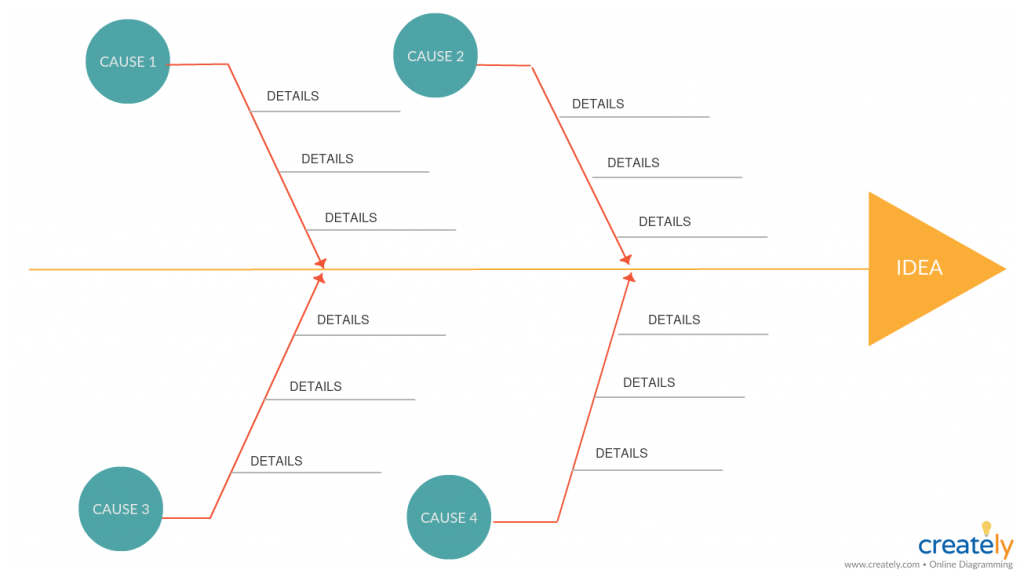

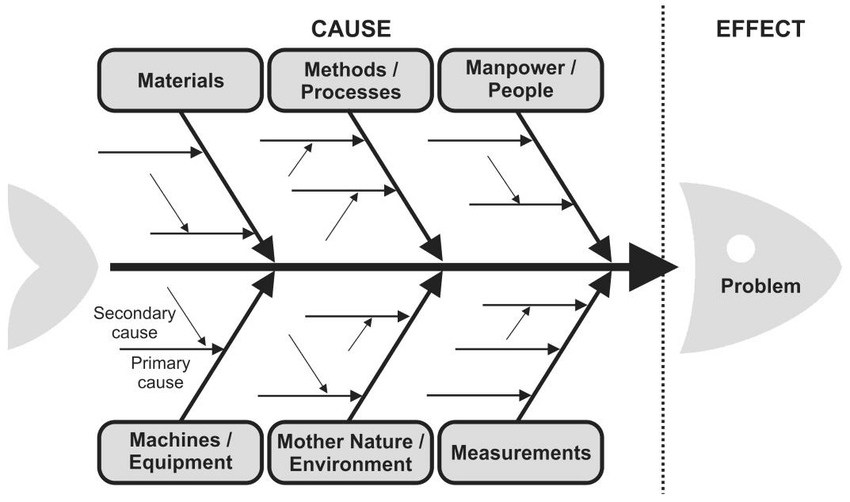

Fishbone Diagram

The Fishbone Diagram is a visual tool that helps teams identify potential root causes of a problem. It is called so because it resembles a fishbone. The fishbone diagram organizes and categorizes possible causes, making it easier to identify the root cause. For example, a fishbone diagram could be used in a manufacturing setting to categorize and analyze the various factors contributing to a machine breakdown, such as equipment design, operator error, or poor maintenance.

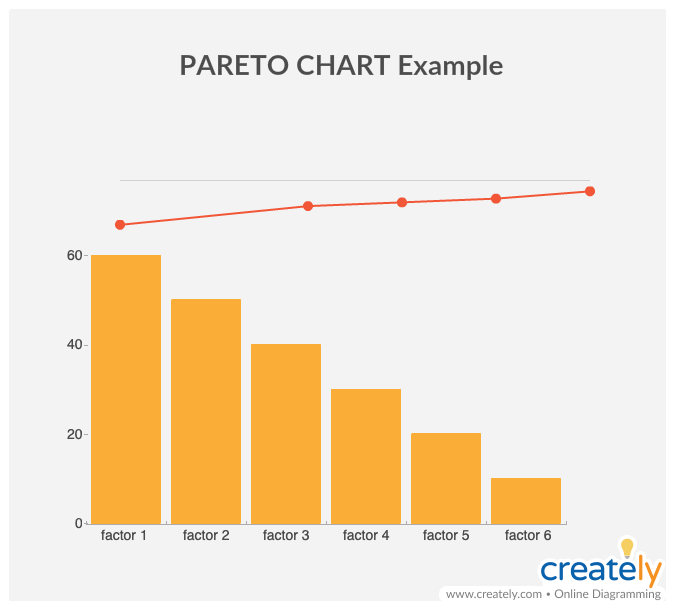

Pareto Analysis

The Pareto Analysis approach uses statistical analysis to identify the most significant root causes of a problem. The Pareto principle states that 80 percent of issues are caused by 20 percent of root causes. Pareto analysis helps teams focus on the most critical root causes, reducing the time and resources required to address the problem. For example, in a healthcare setting, a Pareto analysis could determine that 20 percent of patient falls are caused by 80 percent of the root causes, such as slippery floors, poor lighting, or lack of staff supervision.

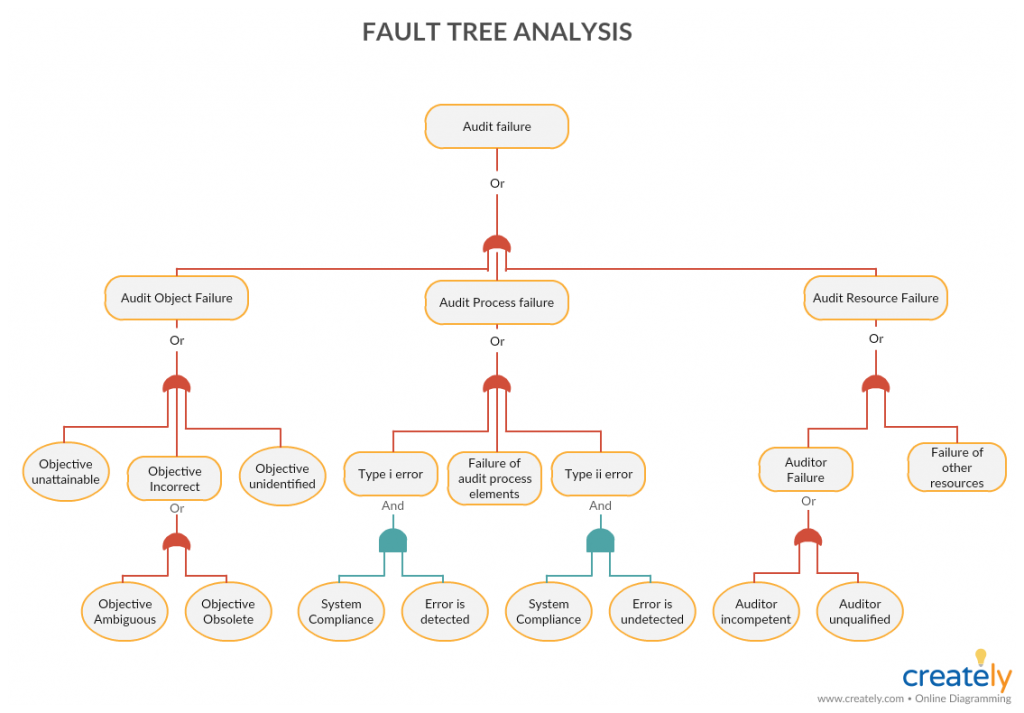

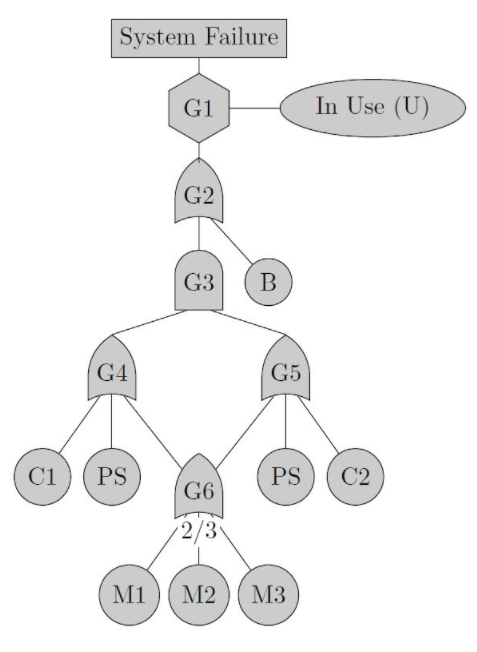

Fault Tree Analysis (FTA)

This type of root cause analysis is a graphical representation of the relationships between different system components and how they contribute to a problem or failure. FTA helps teams understand the interdependencies between various components and identify the root cause of a problem. For example, in an aviation setting, an FTA could be used to analyze the interdependencies between different components of a plane, such as the engines, fuel system, and control surfaces, and to identify the root cause of a crash.

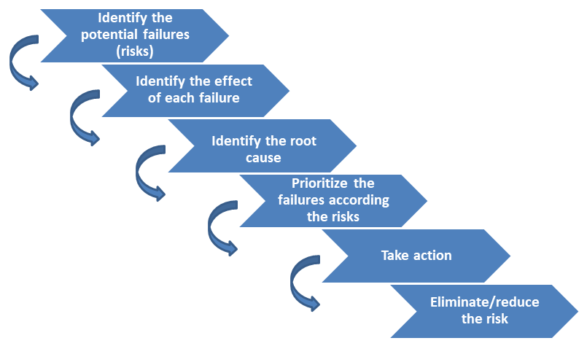

Conducting Root Cause Analysis: Process

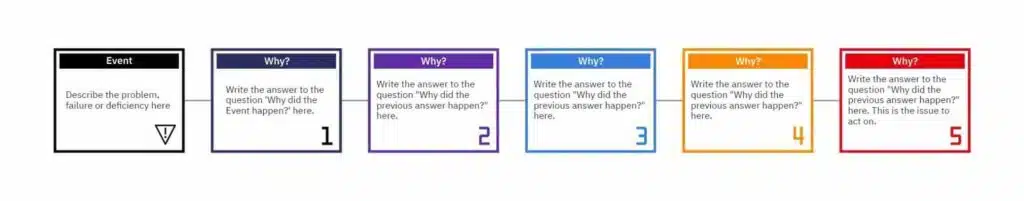

We can break the process of conducting RCA into the following steps:

- Define the problem: The first step is clearly defining the problem and understanding what needs to be addressed.

- Gather data: Once the problem is defined, the next step is to gather data. This involves collecting information about the problem, including date, time, and location, as well as any relevant documentation, reports, or other information.

- Form a team: The next step is forming a team of experts responsible for conducting the RCA. The team should include individuals with expertise in the problem area, as well as representatives from different departments or parts of the organization.

- Use a root cause analysis tool: The team should use a root cause analysis tool, such as a fishbone diagram, Pareto analysis, or fault tree analysis, to help identify potential root causes.

- Identify root causes: Once potential root causes have been identified, the team should use the data and information collected to validate and verify the root causes.

- Develop solutions: Once the root cause has been identified, the team should develop solutions to address the root cause and prevent future occurrences of the problem.

- Implement solutions: The final step is to implement the solutions and monitor their effectiveness to ensure that the problem has been fully resolved.

Also Read: Value Stream Mapping in Six Sigma

Root Cause Analysis Principles

Conducting RCA involves following several fundamental principles:

- Root cause focus: Root cause analysis focuses on discovering and correcting the root causes of a problem rather than just treating the symptoms.

- Short-term relief: While focusing on root causes is essential, it’s also important to provide short-term relief for the symptoms.

- Multiple root causes : Multiple root causes can contribute to a problem, so it’s important to identify all of them.

- No blame: The focus should be on understanding how and why a problem occurred rather than who was responsible.

- Evidence-based: Root cause claims should be supported by concrete cause-and-effect evidence.

- Actionable information: The results of the analysis should provide enough information to inform a corrective course of action.

- Future prevention: Consideration should be given to how the root cause can be prevented from recurring.

Tips for Root Cause Analysis

- Start with a clear definition of the problem: It is essential to have a crystal-clear understanding of the problem before starting the RCA process. This will help ensure that the team is focused on addressing the right issue and that the root cause is accurately identified.

- Gather all relevant data: Data is essential for a successful RCA. The team should gather as much relevant data as possible, including the date, time, and location of the problem, as well as all pertinent documentation, reports, or other information.

- Involve experts from different areas: Involving experts from different areas of the organization, such as operations, maintenance, and engineering, will help ensure that the root cause is accurately identified and that all potential root causes are considered.

- Use multiple tools and techniques: Different RCA tools and techniques, such as fishbone diagrams, Pareto analysis, and fault tree analysis, can provide different perspectives and insights into the root cause of a problem. The team should consider using multiple tools and techniques to ensure they completely understand the problem.

- Be thorough and systematic: RCA should be approached systematically, using a structured process and methodology to identify root causes. The team should be detailed and methodical in their approach to ensure that all potential root causes are considered and that the root cause is accurately identified.

- Focus on prevention: The goal of RCA is not just to identify the root cause of a problem but to prevent future occurrences. The team should focus on developing solutions that will prevent the problem from happening again in the future.

Also Read: Demystifying Kaizen Lean Six Sigma

Master Root Cause Analysis Skills to Become a Lean Six Sigma Expert

For a Lean Six Sigma expert, the ability to identify the underlying causes of problems and develop effective solutions for improving processes and outcomes is a prized skill. As such, you need to understand and know how to perform root cause analysis.

If you’re interested in becoming a Lean Six Sigma expert, an online Lean Six Sigma certification can provide you with the knowledge, skills, and tools you need to succeed in this role.

An online bootcamp like the one delivered by Simplilearn, in collaboration with the University of Massachusetts, covers the core concepts of Lean Six Sigma, including problem-solving methodologies, process improvement techniques, and statistical analysis tools. This IASSC-accredited program teaches how to identify and eliminate waste, reduce defects, and improve process efficiency across various industries.

With business mentoring from industry experts from KPMG, you’ll be able to tackle real-world business problems confidently. This fast-track program is perfect for quality professionals, business analysts, and executives looking to carve successful careers.

Ready to start your journey toward becoming a master in quality management? Enroll today!

You might also like to read:

Ultimate Guide to Six Sigma Control Charts

DMADV: Everything You Need to Know

Describing a SIPOC Diagram: Everything You Should Know About It

Process Mapping in Six Sigma: Here’s All You Need to Know

How to Use the DMAIC Model?

Leave a Comment Cancel Reply

Your email address will not be published. Required fields are marked *

Recommended Articles

Six Sigma in Healthcare: Concepts, Benefits and Examples

Learn how and why Six Sigma methodology is used in healthcare. This blog covers the benefits of Six Sigma in healthcare and explores real-world examples.

Six Sigma Principles: Process Implementation and Optimization

When processes don’t work as they should, productivity suffers, and unexpected variations lead to product defects that compromise customer experience and a company’s bottom line.

What is Process Capability? Index, Formula, Example & Everything to Know

In manufacturing, the key to profitability is consistency. You need to produce products that meet tight guidelines to satisfy customer requirements. Too many defects can

What is Zero Defect? What it Means, its Applications, and Limitations

This guide explores zero defects, a key concept of quality management for Six Sigma professionals. It explains the concept, its importance, and how it can enhance your Six Sigma career.

Quality Management Breakdown: What is Measurement System Analysis?

What is measurement system analysis? This article covers its definition, importance, and fundamentals and dives into types, processes, and real-world applications.

What is Lean Project Management, and How Does It Work?

Explore the basics of Lean project management and how to implement Lean principles to achieve faster project cycles and superior outcomes.

Lean Six Sigma Certification

Learning Format

Online Bootcamp

Program benefits.

- Green and Black Belt exam training material included

- Aligned with IASSC-Lean Six Sigma

- Masterclasses from top faculty of UMass Amherst

- UMass Amherst Alumni Association membership

Root cause analysis (RCA) is the quality management process by which an organization searches for the root of a problem, issue or incident after it occurs.

Issues and mishaps are inevitable in any organization, even in the best of circumstances. While it could be tempting to simply address symptoms of the problem as they materialize, addressing symptoms is an inherently reactive process that all but guarantees a recurring—and often worsening—series of problems.

Ethical, proactive, well-run companies and organizations with a reactive approach will both encounter problems, but the former will experience fewer and recover faster because they prioritize root cause analyses.

Root cause analysis helps organizations decipher the root cause of the problem, identify the appropriate corrective actions and develop a plan to prevent future occurrences. It aims to implement solutions to the underlying problem for more efficient operations overall.

Learn how next-generation detection devices shift asset management services from routine maintenance regimes to predictive, AI-powered processes.

Delve into our exclusive guide to the EU's CSRD

Organizations perform root cause analyses when a problem arises or an incident occurs, but there are any number of issues that need an RCA. Triggers for a root cause analysis fall into three broad categories.

When real-world materials or equipment fails in some way (for example, a desktop computer stops working or a component from a third-party vendor delivers substandard performance).

When people make mistakes or fail to complete required tasks (for example, an employee fails to perform regular maintenance on a piece of equipment, causing it to break down).

A breakdown in a system, process or policy people use to make decisions (for example, a company fails to train team members on cybersecurity protocols, leaving the company vulnerable to cyberattacks ).

Organizations can conduct root cause analyses for a range or reasons, from commonplace email service disruptions to catastrophic equipment failures. Regardless of the nature or scope of the issue, performing root cause analysis should include the same fundamental steps.

If you have decided to conduct a root cause analysis, your department or organization is likely experiencing some acute issue, or at least looking to make substantive improvements to a particular process. Therefore, the first step of the root cause analysis process should be identifying and defining the problem that you want to address. Without a clearly defined problem, it is impossible to correctly identify the root causes.

When the department has a clear idea of the problem, it’s time to draft a problem statement spelling out the issue for everyone who will help with the RCA.

Once the issue is identified and clearly articulated to all involved parties, leadership should create a project charter, which will assemble a team to complete the analysis. The team should include a facilitator to lead the team through the analysis and any team members with either personal or professional knowledge of the systems, processes and incidents that you will investigate.

Data collection is the foundation of the problem-solving process. It is vital, at this stage, to find every piece of information that can help you identify contributing factors and ultimately the root causes of the issue. This can include collecting photographs and incident reports, conducting interviews with affected parties and reviewing existing policies and procedures. Some questions that you may want to ask during data collection:

- When did the problem start and how long has it been going on?

- What symptoms has the team observed?

- What documentation does the organization or department must prove that an issue exists?

- How will the issue affect employees and other stakeholders?

- Who is harmed or otherwise affected by the existence of this problem?

This is the most important step in the RCA process. At this point, the team has collected all necessary information and starts to brainstorm for causal factors. Effective root cause analyses require openness to all potential underlying causes of an issue, so everyone on the RCA team should enter the brainstorming stage with an open mind. Avoid attempts to determine root causes until every possibility is identified and vetted; starting the incident investigation process with preconceived notions may bias the results and make it more difficult to determine the real root cause.

Once the RCA team has an exhaustive list of possible causes and contributing factors, it is time to determine the root causes of the issue. Analyze every possible cause and examine the actual impact of each one to figure out which possibilities are the most problematic, which ones have similarities and which ones can be altogether eliminated. Be prepared for the possibility that there are multiple root causes to the issue.

After the team narrows the list of possibilities, rank the remaining potential root causes by their impact and the likelihood they are the root cause of the problem. Leadership will examine and analyze each possibility and collaborate with the RCA team to determine the actual root causes.

Once the team settles on root causes and has laid out all the details of the issue, they must start brainstorming solutions. The solution should directly address the root causes, with consideration for the logistics of executing the solution and any potential obstacles the team may encounter along the way. These elements will comprise the action plan that will help the team address the current problem and prevent recurrences.

While all RCAs will include the same basic steps, there are myriad root cause analysis methods that can help an organization collect data efficiently and effectively. Typically, a company will select a method and use root cause analysis tools, such as analysis templates and software, to complete the process.

The 5 Whys approach is rooted in the idea that asking five “Why?” questions can get you to the root cause of anything. 5 Whys implores problem solvers to avoid assumptions and continue to ask “why” until they identify the root cause of a problem. In the case of a formalized organizational root cause analysis, a team may only need to ask three whys to find the root cause, but they may also need to ask 50 or 60. The purpose of 5 Whys is to push the team to ask as many questions as is necessary to find the correct answers.

A failure mode and effects analysis is one of the most rigorous approaches to root cause analysis. Similar to a risk analysis, FMEA identifies every possibility for system/process failure and examines the potential impact of each hypothetical failure. The organization then addresses every root cause that is likely to result in failure.

Pareto charts combine the features of bar charts and line charts to understand the frequency of the organization’s most common root causes. The chart displays root causes in descending order of frequency, starting with the most common and probable. The team then addresses the root cause whose solution provides the most significant benefit to the organization.

An impact analysis allows an organization to assess both the positive and negative potential impacts of each possible root cause.

Change analyses are helpful in situations where a system or process’s performance changed significantly. When conducting this type of RCA, the department looks at how the circumstances surrounding the issue or incident have changed over time. Examining changes in personal, information, infrastructure, or data, among other factors, can help the organization understand which factors caused the change in performance.

An event analysis is commonly used to identify the cause of major, single-event problem, like an oil spill or building collapse. Event analyses rely on quick (but thorough) evidence-gathering processes to recreate the sequence of events that that led to the incident. Once the timeline is established, the organization can more easily identify the causal and contributing factors.

Also known as a causal factor analysis, a causal factor tree analysis allows an organization to record and visually display—using a causal factor tree—every decision, event or action that led to a particular problem.

An Ishikawa diagram (or Fishbone diagram) is a cause-and-effect style diagram that visualizes the circumstances surrounding a problem. The diagram resembles a fish skeleton, with a long list of causes grouped into related subcategories.

DMAIC is an acronym for the Define, Measure, Analyze, Improve and Control process. This data-driven process improvement methodology serves as a part of an organization’s Six Sigma practices.

This RCA methodology proposes finding the root cause of an issue by moving through a four-step problem solving process. The process starts with situation analysis and continues with problem analysis and solution analysis, concluding with potential problem analysis.

An FTA allows an organization to visually map potential causal relationships and identify root causes using boolean logic.

Barrier analyses are based on the idea that proper barriers can prevent problems and incidents. This type of RCA, often used in risk management, examines how the absence of appropriate barriers led to an issue and makes suggestions for installing barriers that prevent the issue from reoccurring.

Companies that use the RCA process want to put an end to “firefighting” and treating the symptoms of a problem. Instead, they want to optimize business operations, reduce risk and provide a better customer experience. Investing in the root cause analysis process provides a framework for better overall decision-making and allows an organization to benefit from:

Continuous improvement : Root cause analysis is an iterative process, seeking not only to address acute issues, but also to improve the entire system over time, starting with the underlying cause. The iterative nature of root cause analysis empowers organizations to prioritize continuous process improvement.

Increased productivity : Preventing downtime, delays, worker attrition and other production issues within an organization saves employees time, freeing up bandwidth to focus on other critical tasks.

Reduced costs : When equipment breaks down or software bugs cause delays, organizations lose money and workers get frustrated. Root cause analysis helps eliminate the cost of continually fixing a recurring issue, resulting in a more financially efficient operation overall.

Better defect detection : When companies fail to address underlying issues, they can inadvertently affect the quality of the end product. Addressing persistent problems before they snowball protects the organization from revenue and reputational losses that are associated with product defects down the line.

Reduced risks : Improving business processes and systems keeps equipment running safely and helps workers avoid safety hazards in the workplace.

Intelligent asset management, monitoring, predictive maintenance and reliability in a single platform.

Enhance your application performance monitoring to provide the context you need to resolve incidents faster.

IBM research proposes an approach to detect abnormality and analyzes root causes using Spark log files.

Learn how IBM Instana provides precision hybrid cloud observability, metrics, traces and logs.

Downer and IBM are using smart preventative maintenance to keep passengers on Australia's light and heavy rail systems moving safely, reliably, comfortably and more sustainably.

Unlock the full potential of your enterprise assets with IBM Maximo Application Suite by unifying maintenance, inspection and reliability systems into one platform. It’s an integrated cloud-based solution that harnesses the power of AI, IoT and advanced analytics to maximize asset performance, extend asset lifecycles, minimize operational costs and reduce downtime.

Root Cause Analysis (RCA) Methods for Effective Problem Solving

Imagine facing a problem in your organization that keeps recurring despite your best efforts to solve it. You might be addressing the symptoms, but not the underlying cause. This is where root cause analysis (RCA) comes into play. RCA is a systematic approach to identifying the root cause of problems or events, understanding how to fix or compensate for them, and applying the knowledge gained to prevent future issues or replicate successes. In this comprehensive guide to root cause analysis, you’ll learn various methods and techniques for conducting an RCA. You’ll understand how to gather and manage evidence, investigate the people, processes, and systems involved, and determine the key factors leading to the problem or event.

Whether you’re a project manager, a team leader, or simply someone looking to improve your problem-solving skills, this guide will help you grasp the fundamentals of RCA and apply them effectively in your work. As you delve deeper into the world of Root Cause Analysis, you’ll discover how it can turn challenges into opportunities for growth and pave the way for a more efficient and successful future.

Related: 3 Root Cause Analysis Templates (and Examples)

5 Whys: How to Uncover Root Causes [Examples]

Root Cause Analysis Fundamentals

Root Cause Analysis (RCA) is a systematic approach to identify the underlying cause of a problem. By focusing on the root cause, you can effectively address the issue and prevent recurrence. Generally, RCA is used to investigate incidents, eliminate defects, and enhance systems or processes.

RCA aims to achieve the following objectives:

- Determine the root cause of a problem or issue, not just its symptoms.

- Identify and implement solutions that address the root cause and prevent its recurrence.

- Improve understanding of the systems, processes, or components involved to avoid similar issues in the future.

- Foster a proactive and continuous improvement mindset within your organization.

When conducting RCA, maintain an open mind and avoid making assumptions. Utilize critical thinking and involve team members from various disciplines to achieve a comprehensive understanding of the problem.

The RCA Process

Problem identification.

To effectively utilize Root Cause Analysis (RCA), first identify the problem at hand. Determine the specific issue, incident, or failure that needs to be investigated. Clearly define the problem and its impact on your organization’s operations in order to establish a focused and valuable analysis.

Data Collection

Gather relevant data about the problem, including when and where it occurred, who was involved, what processes and systems were affected, and any other important context. Be thorough and systematic in your data collection, and make use of any available documentation, interviews, or observations to build a comprehensive understanding.

Cause Identification

Analyze the collected data to pinpoint potential causes of the problem. This could start with brainstorming and then using tools such as cause-and-effect diagrams or the “5 Whys” technique to delve deeper into the issue. Determine the causes that are most likely to have contributed to the problem and classify them as either root causes or contributing factors.

Solution Implementation

Once you have identified the root cause(s) of the problem, develop and execute an action plan to address the issue. Design solutions that specifically target the root cause(s) to eliminate them from your processes, rather than simply addressing the symptoms of the problem. Implement the appropriate changes to your processes or systems and ensure that all stakeholders are aware of these changes.

Follow-up and Monitoring

After implementing the solutions, monitor the results to ensure they are effective in addressing the root cause(s) and preventing the problem from reoccurring. Collect and analyze data regularly to evaluate the impact of the implemented solutions on your organization’s performance. Adjust and refine the solutions if necessary, and maintain ongoing vigilance in order to identify any future problems that may arise from the same root cause(s).

RCA Techniques

The 5 Whys technique is a straightforward method for identifying the root cause of a problem. To employ this approach, you simply ask “why” five times, with each question delving deeper into the issue. The process helps trace the problem to its origin by examining each level of cause and effect. Here’s an example:

- Why did the machine stop working?

- Why did the fuse blow?

- Why did the motor overheat?

- Why was there insufficient lubrication on the motor?

- Why was the lubrication schedule not followed?

In this case, the root cause is the failure to adhere to the lubrication schedule.

Learn more: 5 Whys: How to Uncover Root Causes [Examples]

Fishbone Diagram

The Fishbone Diagram, also known as the Ishikawa Diagram or cause-and-effect diagram, is a visual tool that helps you organize and sort potential root causes. To create a Fishbone Diagram:

- Write down the problem statement at the head of the fishbone structure.

- Identify major categories of causes, such as people, process, equipment, and environment. Draw lines connecting them to the problem statement.

- Assign specific causes under each category and draw smaller lines connecting them to the respective major categories.

- Analyze the diagram to find trends, patterns, or potential areas of focus.

By organizing information in this way, you can better assess the causes and identify the root cause of the problem.

Learn more: Fishbone Diagram (Components, Factors, Examples) and Ishikawa Diagram: Examples and Applications

Failure Modes and Effects Analysis (FMEA) is a systematic approach to identify potential failures and evaluate the consequences. FMEA processes typically involve these steps:

- Identify potential failure modes, which are the ways something could go wrong.

- Determine the potential effects of each failure mode, and how it could impact the overall system or process.

- Assign a risk priority number (RPN) to each failure mode, considering factors such as likelihood, severity, and detectability.

- Develop actions and strategies to mitigate high-risk failure modes.

By using FMEA, you can proactively address possible issues before they escalate, and maintain a more reliable process or system.

Barrier Analysis

Barrier Analysis focuses on preventing problems by examining the barriers in place to control risks. The objective is to identify vulnerabilities in these barriers and develop strategies for improvement. The steps of Barrier Analysis include:

- Identify hazards and risks associated with your system or process.

- Define the barriers in place that protect against these hazards.

- Evaluate the effectiveness, strength, and reliability of each barrier.

- Identify gaps or weaknesses in the barriers.

- Develop and implement improvements to strengthen the barriers.

This method provides a clear understanding of how existing safety measures perform and how they can be improved to better protect against potential issues.

See also: 3 Root Cause Analysis Templates (and Examples)

What is Poka-Yoke? [Examples, Principles, Methods]

Benefits of Root Cause Analysis

Quality improvement.

Root cause analysis can significantly enhance the quality of your products or services. By systematically identifying the root causes of issues and implementing corrective actions, you’ll prevent recurring problems and reduce the number of defects. In turn, this will help you maintain customer satisfaction, reduce costs associated with rework or returns, and improve your reputation in the market.

Risk Reduction

Reducing risk is another advantage of root cause analysis. When you identify the underlying causes of problems, you can take necessary measures to eliminate or mitigate those risks. This proactive approach can protect your business from potential losses or disruptions, such as regulatory penalties, customer dissatisfaction, or harm to employees or the environment. By addressing the sources of risk, you can maintain a safer and more profitable business.

Process Optimization

Root cause analysis supports continuous improvement by highlighting inefficiencies and areas for optimization in your operations. By examining your processes beyond the symptoms of a specific issue, you can uncover opportunities to streamline workflows, reduce waste or downtime, and better utilize resources. Implementing these improvements not only resolves the immediate problem but also enhances overall productivity and efficiency in your organization.

To attain the benefits of root cause analysis, apply it consistently and rigorously. Ensure that you involve relevant stakeholders, gather necessary data, and employ a systematic approach to identifying and addressing root causes.

Challenges of Root Cause Analysis

Common pitfalls.

When conducting Root Cause Analysis (RCA), you might face common pitfalls that can reduce the effectiveness of your investigation. Some of these pitfalls include:

- Rushing the process : It is important to allocate appropriate time and resources to conduct a thorough RCA.

- Overlooking small details : Make sure to pay attention to all possible contributing factors when investigating a problem. Small details can often hold the key to the root cause.

- Focusing on blame : RCA should focus on identifying systemic issues and providing solutions rather than blaming individuals or departments.

Addressing Human Factors

Human factors play a critical role in many problems. When conducting RCA, it is crucial to consider the human factors that may have contributed to the issue. Here are some tips to help you address human factors in your RCA:

- Consider psychological factors : Assess the mental state of the people involved in the incident, including their level of stress, fatigue, and emotions.

- Evaluate communication and collaboration : Analyze how effectively teams were communicating and working together at the time of the incident.

- Assess training and competency : Determine if the people involved had the appropriate training and knowledge to handle the situation.

Keep a neutral and non-blaming tone while assessing human factors. The aim is to uncover systemic issues that can be improved upon.

Fishbone Diagram (Components, Factors, Examples)

Ishikawa Diagram: Examples and Applications

- Advantages of SWOT Analysis (6 Benefits and 4 Limitations)

- 8 Examples: Top Problem Solving Skills

- What is Problem Solving? (Steps, Techniques, Examples)

Have a language expert improve your writing

Run a free plagiarism check in 10 minutes, generate accurate citations for free.

- Knowledge Base

- Starting the research process

- What Is Root Cause Analysis? | Definition & Examples

What Is Root Cause Analysis? | Definition & Examples

Published on January 6, 2023 by Tegan George . Revised on November 17, 2023.

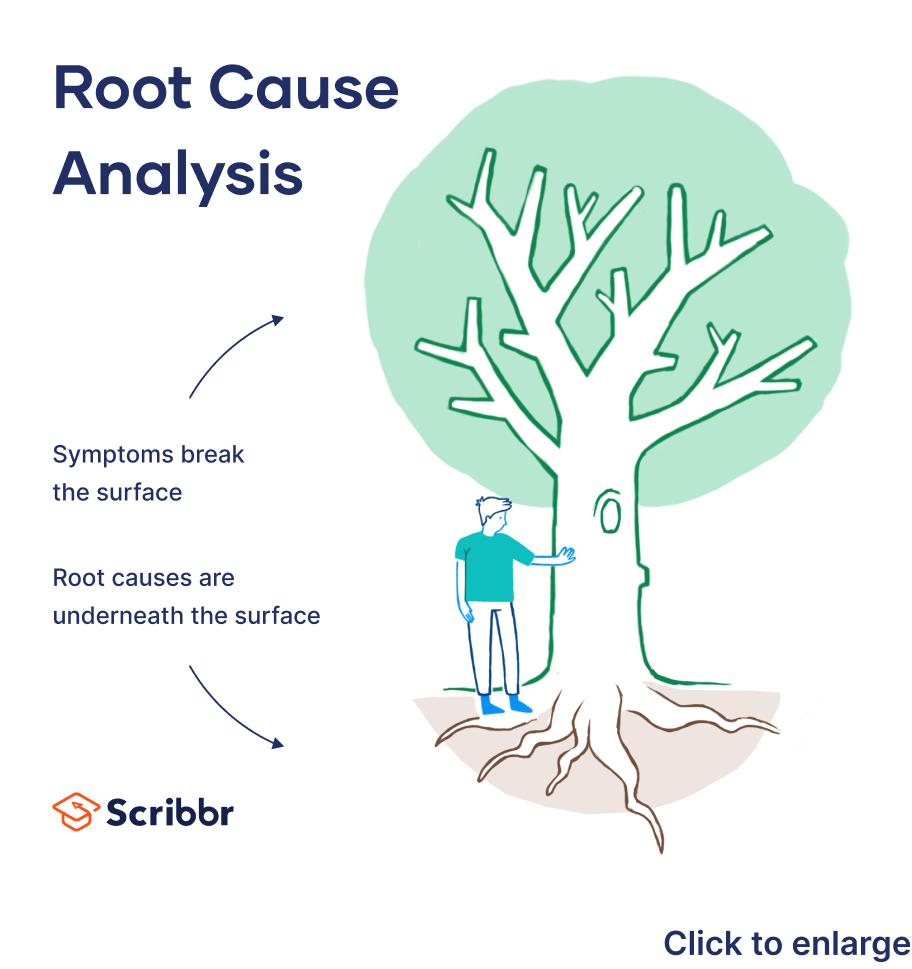

Root cause analysis is a problem-solving approach that uses the analogy of roots and blooms to model cause-and-effect relationships. Rather than focusing on what’s above the surface, root cause analysis troubleshoots solutions to problems by analyzing what is causing them. Note Similarly to exploratory research , it’s important to remember that root cause analysis does not provide solutions to problems. Rather, it’s one method within a larger problem-solving landscape.

Root cause analysis is a form of quality management, often used in organizational management, quality control, and in healthcare fields like nursing. Root cause analysis can be a helpful study tool for students, too, when used for brainstorming or memorization exercises.

Table of contents

Root cause analysis template, the “5 whys” of root cause analysis, advantages and disadvantages of root cause analysis, other interesting articles, frequently asked questions.

It’s easy to draw root cause analysis charts by hand, on a whiteboard or a big piece of paper. Many people use fishbone diagrams as well, or you can download our template below.

Here's why students love Scribbr's proofreading services

Discover proofreading & editing

One of the most common ways to conduct root cause analysis is using the “5 Whys” method, popular in lean management. The 5 Whys are an interconnected method of analysis: after defining your problem, you ask “why?” and answer as concisely as possible. The first “why” often leads to the second, which leads to the third, etc.

In short, you continue to ask “why” until the answer provided is no longer a contributor to the broader issue, but a possible solution to that issue. In other words, as you strategize, you’ll sense it’s time to stop when a provided answer has the potential to stop the whole problem from occurring, rather than only one aspect of that problem. This often takes 3-5 “whys” but can definitely stretch out for longer.

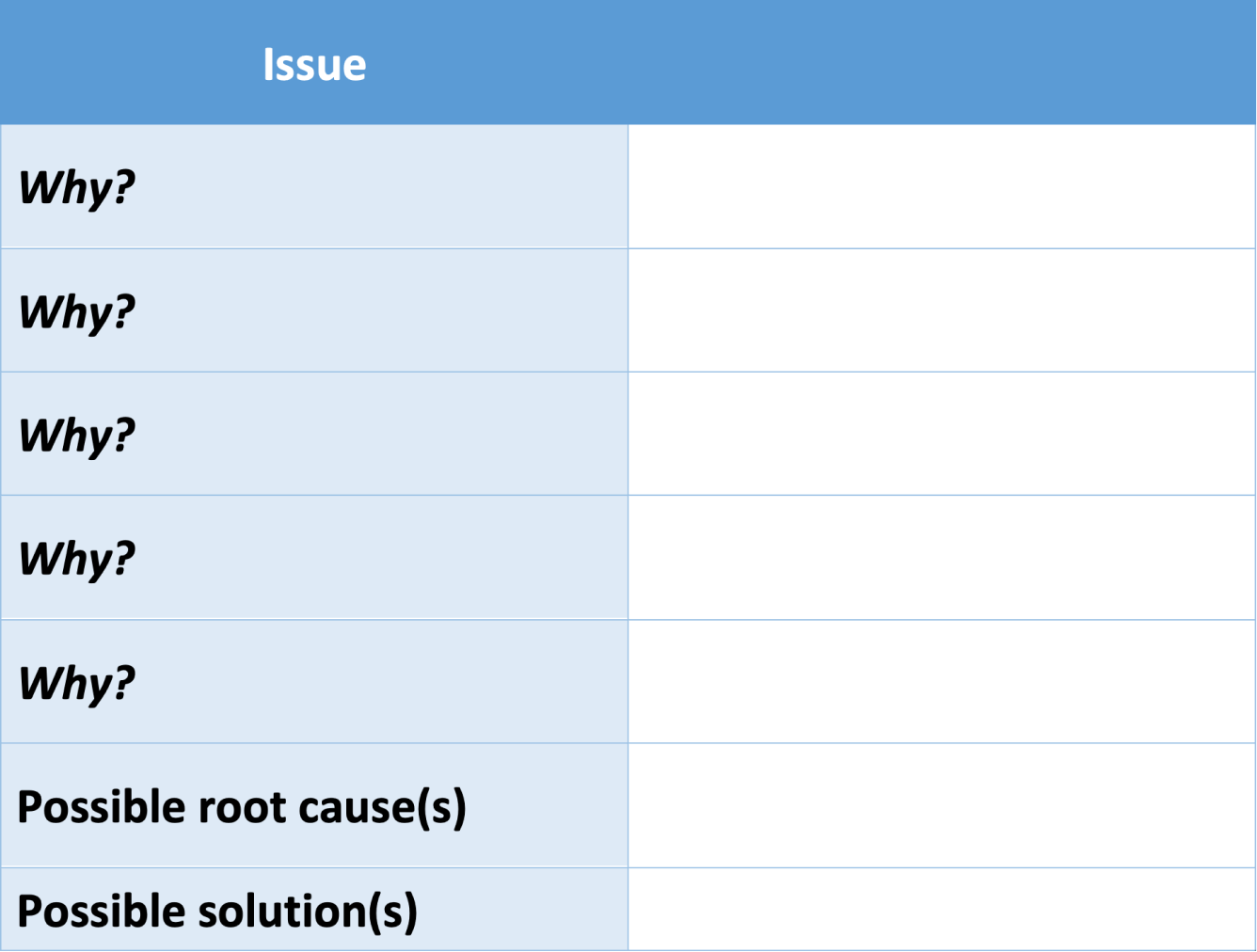

You can use this template to map out your whys.

Root cause analysis is a great way to organize your thoughts, but its simplicity leads to a few downsides.

- Great brainstorming tool for individual or group projects.

- Can help identify causal relationships and clarify relationships between variables .

- “5 whys” system can help simplify complex issues and drive possible solutions.

Disadvantages

- Can be overly simplistic, not leaving much room for nuance or variations.

- Path dependence can occur if the wrong question is asked, leading to incorrect conclusions.

- Cannot provide answers, only suggestions, so best used in the exploratory research phase .

If you want to know more about the research process , methodology , research bias , or statistics , make sure to check out some of our other articles with explanations and examples.

Methodology

- Sampling methods

- Simple random sampling

- Stratified sampling

- Cluster sampling

- Likert scales

- Reproducibility

Statistics

- Null hypothesis

- Statistical power

- Probability distribution

- Effect size

- Poisson distribution

Research bias

- Optimism bias

- Cognitive bias

- Implicit bias

- Hawthorne effect

- Anchoring bias

- Explicit bias

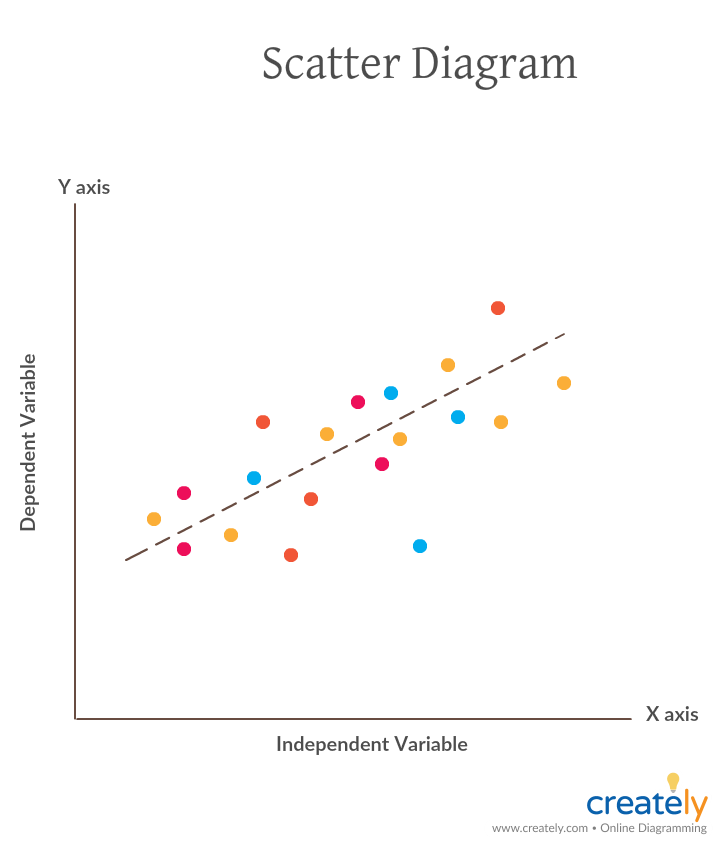

There are several common tools used for root cause analysis , the most popular of which include fishbone diagrams , scatterplots, and the “5 whys.”

A fishbone diagram is a method that can be used to conduct root cause analysis.

Cite this Scribbr article

If you want to cite this source, you can copy and paste the citation or click the “Cite this Scribbr article” button to automatically add the citation to our free Citation Generator.

George, T. (2023, November 17). What Is Root Cause Analysis? | Definition & Examples. Scribbr. Retrieved September 3, 2024, from https://www.scribbr.com/research-process/root-cause-analysis/

Is this article helpful?

Tegan George

Other students also liked, what is a fishbone diagram | templates & examples, how to write a problem statement | guide & examples, how to define a research problem | ideas & examples, "i thought ai proofreading was useless but..".

I've been using Scribbr for years now and I know it's a service that won't disappoint. It does a good job spotting mistakes”

Advisory boards aren’t only for executives. Join the LogRocket Content Advisory Board today →

- Product Management

- Solve User-Reported Issues

- Find Issues Faster

- Optimize Conversion and Adoption

Better problem solving with root cause analysis (with template)

If you walk into your kitchen to find your favorite vase smashed on the floor, it might be safe to assume that the grinning cat nearby was the root cause of this problem. If only it was this simple in business and we could just say “the cat did it.” Product problems are often much more complex and connected to a variety of root causes.

If you think of a weed, the surface is only the problem you can immediately see. However, if you cut the weed from the ground level, it’s likely to grow back from the root. This is just like fixing product problems with a band-aid with little to no investigation of a root cause — it’s likely to return.

These types of problems need a more thorough root cause analysis (RCA) to determine how, and why the problem happened, and how to prevent it in the future.

What is root cause analysis?

Root cause analysis is a tool you can utilize when determining the true cause of a problem. You might have assumptions about what the cause of a problem might be or experience biases towards one as the main cause.

Performing a root cause analysis can help you determine what the underlying causes of a problem are to help address a more impactful and valuable solution:

What are the 4 steps in a root cause analysis?

When you’re trying to uncover the roots of a problem, it can be daunting to figure out where to start. The process to conduct a root cause analysis can be broken down into a few easy steps:

- Define the problem

- Identify and map the problem causes

- Identify the evidence that supports your causes

- Create a root cause analysis report and set up your action plan

1. Define the problem

A clear definition of the problem is the first step. Sometimes problems are easy to identify, like a broken link. More often, problems can be abstract and need clarification, like a decrease in overall purchases through a site or an increase in bugs reported.

Here are some more examples of problems:

- A 20 percent drop in customer purchases placed from the shopping cart page from the previous week

- 60 percent of customers on hold end up dropping their call and, as a result, the company has experienced a decrease in NPS scores

- A 40 percent increase of customer reported issues with using the folders feature in a CRM

- A 15 percent decrease in user engagement with a core feature on a social media site

It’s also critical to understand how to define a problem:

| Evaluate the urgency | Is this a currently existing issue? Could it become a larger problem? Has this problem occurred before and could it happen again? |

| Describe the impact | How does this impact the business? How do the numbers compare to the baseline? What are some of the unintended consequences of this problem? A business with seasonal needs, such as tax preparation products, will see an increase in their average number of customer service calls during tax season. If not prepared for an increase in call volume, they could experience an increase of customer dropped calls, lower NPS scores, and a big impact to their overall business success. |

| Collect evidence | , usage data, and anything that might highlight the problem. Talk with stakeholders, and, if possible, users who are directly impacted by the problem. Sometimes, you might hear of a “huge” problem from a user only to find out that the impact is quite small overall from data evidence. Collecting evidence to evaluate the impact is a crucial step to ensure you’re not over or under reacting to a problem. See more about data collection below to learn about common key metrics in a RCA. |

2. Identify and map the problem causes

Using tools like a fishbone analysis and the Five Whys framework can help you put together causes and start to categorize themes of the problem. When going through a Five Whys diagram, try to come up with a few alternate pathways and you might notice overlapping areas.

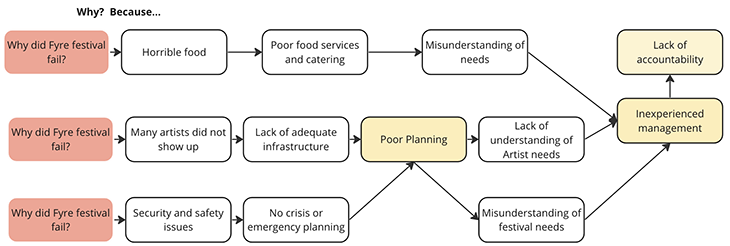

Each example of a Five Whys diagram is accurate, but only looking at one cause can prevent you from understanding the fuller picture. For example, there was more than one reason why the Fyre Festival failed and it’s important to identify overlapping themes to avoid leaning on only one cause:

In a product example, there might be numerous reasons why session times have decreased, or user reported bugs are up.

After evaluating the size, impact, general cause themes, and urgency of the problem, you’ll have a better understanding of how much effort will be needed for the analysis. The larger the problem on the surface, the more underlying causes you might find. Even simple problems can sometimes have numerous causes to consider and you need to determine how in-depth you need to dig to “unroot” the causes.

It’s also critical to check all your bases. Once you have evaluated and categorized the different potential causes to a problem, use the following as a checklist to ensure you’re covering all areas of where and how this problem happened. Be sure to identify any changes or recent events that might have occurred that could have impacted the problem.

- Demographics : is the problem happening to one specific demographic? Only happening to iPhone users? Users in a specific location?

- Time specific : when did the problem happen? Is it continuing to happen? Did the problem only occur during a specific time? You might discover that the problem is related to a time-specific cause, like a release or outage

- User journey : did anything change within the user journey? Map the workflow to determine if any new developments have occurred

- External factors : is this an issue with a third party integration? Did a competitor launch a successful new feature that might be taking business from you? Some of these external factors could be out of your control, but important to recognize

- Internal factors : how many feature releases happened during this time frame? Was there any product downtime or maintenance at that time?

3. Identify the evidence that supports your causes

Collecting evidence is a key part of a root cause analysis. Without evidence, your problem causes are based on assumptions and potentially harmful biases.

Start evaluating any data you might have available. Using session replay tools like LogRocket can help you collect evidence of the problem. Here are a couple of examples of the type of data that can be used to collect evidence:

- User count — number of users impacted by the problem

- Usage — daily, weekly, or monthly active users and a decrease or increase in session time

- Decrease or increase in events — for example, a decrease in users selecting the Add to cart button from a page or an increase in error pages

- Error tracking and user frustration — tools like LogRocket can help track where things are going wrong in your product and surface critical issues

- Qualitative evidence — run user interviews or user-submitted feedback with tools like Loom. Are multiple users running into the same roadblock? Are you seeing the same complaint from multiple users in feedback tickets?

4. Create a root cause analysis report and set up your action plan

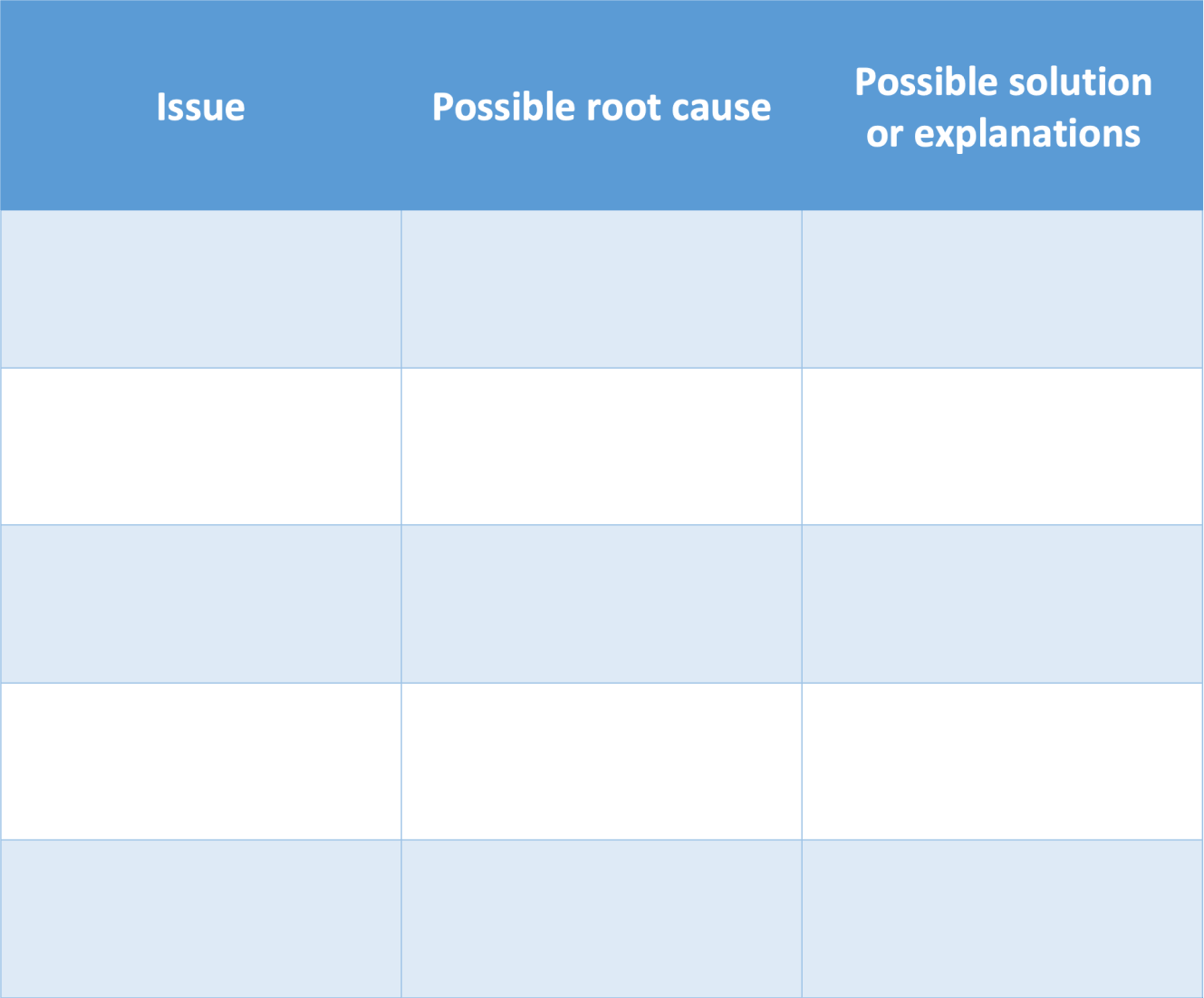

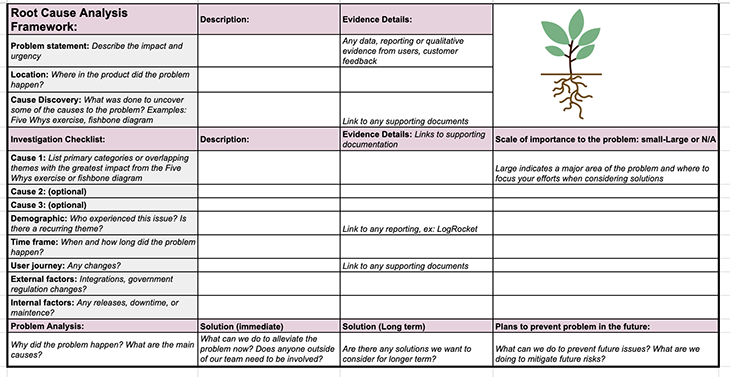

Collect your evidence and root cause evaluation into an RCA template. Once you have your causes identified and your discovery efforts into one root cause analysis report, you can start creating a plan to address the problem and prevent it from happening in the future.

Over 200k developers and product managers use LogRocket to create better digital experiences

Collaborate with a team to brainstorm solutions and discuss which options might address multiple causes. Evaluate if you need both a short-term and long-term solution, depending on the level of effort and urgency required. As part of your analysis report, discuss how you can avoid this problem again in the future and any other risk mitigation plans.

Root cause analysis template

You can use this root cause analysis template on Google Sheets to organization your investigation, collect your evidence, and share with your team to determine next step solutions:

Root cause analysis example

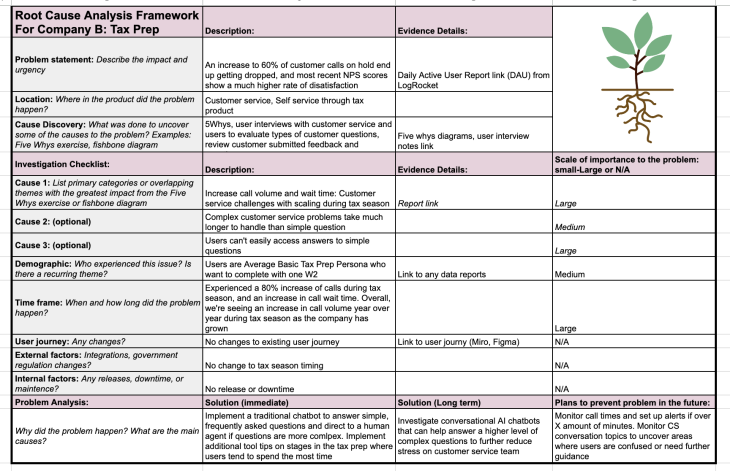

Below is an RCA for Company B, a tax preparation product that experienced an increase in dropped customer calls.

Company B experienced an increase of 60 percent of customers on hold that ended up dropping their call. They also experienced an increase in NPS dissatisfaction and have concerns about losing customers.

After going through a root cause analysis, they discovered an 80 percent increase in user calls during tax season. This increase of call volume indicated much longer wait times to speak to a live agent.

After investigating some of the customer call reasons, they discovered that numerous customers had simple questions that could be answered quickly without too much support.

Company B gathered call logs that confirmed their suspicions. They brought the logs together that demonstrated the simplicity of repeated questions and gathered records of customers that dropped off after a certain amount of time on the phone.

Company B implemented a conversational AI chatbot that could answer generic questions and direct more complex questions to a live agent. Further, they implemented tooltips throughout the tax process flow to help users that appeared to be stuck.

Through the RCA process, you might discover that some parts of the user’s experience are confusing and create a plan to address minor UI challenges.

These solutions helped Company B improve their accessibility and scalability needs during an increase in call volume, without having to add more employee support. Going forward, Company B can plan to monitor call times and continuously evaluate customer service topics to determine where users might need further support and guidance in the future:

Common mistakes to avoid

There are a number of easy-to-fall-into traps when performing root cause analysis, including:

- Don’t rely on assumptions when determining root causes. Use evidence to support to disprove a cause

- Don’t limit your investigation. Go beyond one Five Why framework and be sure to exhaust all possibilities to avoid leaning on the first cause

- Don’t rely on the first idea — come up with multiple solutions to solve a problem

- Don’t work alone. Collaborating with a team will help you come up with a variety of potential solutions or new opportunities

- Don’t think this is a one-time thing. Prepare for the future and discuss risk management and mitigation if you expect this problem to happen again, especially with issues that might be related to factors out of your control. What’s the worst that can happen, and what can we do about it to make sure the problem is addressed quickly with minimal interruption?

Final thoughts

A root cause analysis can be a great tool to help you uncover the true causes of a problem and reduce any reliance on assumptions or biases. With the right investigation and evidence collection, you can learn more about how and why a problem happened and identify causes below the surface.

RCA can ensure your solutions address the root problem and help you better plan for the future.

Featured image source: IconScout

LogRocket generates product insights that lead to meaningful action

Get your teams on the same page — try LogRocket today.

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Reddit (Opens in new window)

- Click to share on LinkedIn (Opens in new window)

- Click to share on Facebook (Opens in new window)

- #product strategy

Stop guessing about your digital experience with LogRocket

Recent posts:.

7 steps to winning at product strategy

With so many conflicting sources of information, it can be difficult to grasp how to actually implement a sound product strategy.

Leader Spotlight: Solving people problems, with Alec Fullmer

Alec Fullmer, Head of Product at Angel Studios, shares how focusing on users instead of the product is the best way to solve people problems.

Positioning your product in an AI-driven market

Can a product succeed without embracing AI, or does it risk being left behind? Let’s discuss ways to integrate AI in your product strategy.

What is the ladder of abstraction?

As a product manager, you need to strike the right balance between high-level strategic thinking and detailed execution.

Leave a Reply Cancel reply

- Announcements

- Brainstorming

- Development

- HR Planning

- Infographics

- IT & Operations

- Marketing & Sales

- Meeting & Visual Collaboration

- Product Management

- Production & Manufacturing

- Project Management

- Remote Working

- Research & Analysis

- Software Teams

- Strategy & Planning

- Template Roundup

- Uncategorized

Root Cause Analysis Guide for Efficient Business Problem-Solving

Updated on: 5 January 2023

Sometimes things go wrong. Well-planned projects fail, processes break down and employees lose their productivity.

To understand what happened, you need to get to the bottom of things.

Many organizations use the root cause analysis when a problem or something unplanned happens that will interrupt their business processes. It helps dig deeper and find effective solutions.

In this post, we will look at what is root cause analysis, the root cause analysis steps, and root cause analysis tools.

What is Root Cause Analysis

Root cause analysis is a method that helps understand the primary cause of a problem or why a problem occurred in the first place.

It helps you to dig into the underlying causes of the situation, thus allowing you to find appropriate solutions for it.

There are several root cause analysis tools and techniques that can be used in the investigation of a problem. But before we get to that, let’s understand how to conduct a root cause analysis first.

Root Cause Analysis Steps

A root cause analysis may take several hours of your time.

It would be easier for you if you involve a team of relevant people; for example, if you are investigating bottlenecks in a process, it would help to have the process owner and other experts for the analysis.

Follow the steps below to conduct a successful root cause analysis.

Step 1: Define the problem

Define the problem your organization is facing and gather data and evidence relevant to it and necessary to understand the current situation.

Create a problem statement which should include information about the problem like the actual impact, potential impact, the focal point, etc. However keep the statement concise.

Step 2: Determine the factors that caused the problem.

Gather a team of people directly involved in the execution of the process and corrective actions, and experts whose input can help find solutions faster.

Together with the team, brainstorm the possible factors for the problem by asking ‘why?’. You can use a 5 whys diagram or a fishbone diagram here.

Step 3: Identify the root cause.

Dig deeper by continuing to ask why after the first layer of causal factors. Keep at it until finally you have discovered the fundamental cause for the problem at hand.

Step 4: Decide the corrective actions

Decide the corrective actions you need to take to eliminate the problem and prevent it from recurring. Make sure that you clearly communicate them to the people who will be involved.

Step 5: Review and evaluate

Review and evaluate the impact of the corrective actions. Make improvements as necessary.

Root Cause Analysis Tools

Many root cause analysis tools are out there. Following we have listed some that are widely used and more effective in problem-solving.

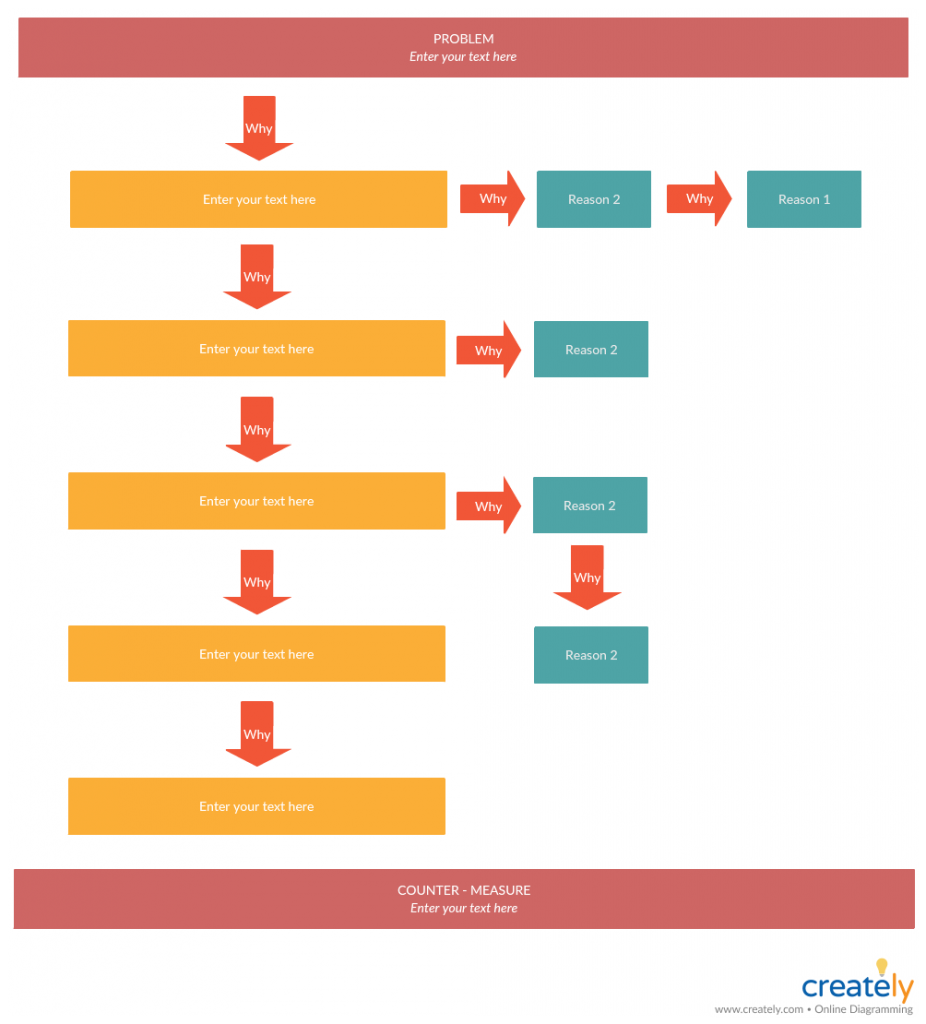

5 Whys Analysis

To carry out a 5 whys analysis, you need to gather a team of people who are affected by the problem.

As the name suggests, in the 5 whys analysis the question ‘why?’ is asked five times in the course of finding the root cause of a problem.

You can use a 5 whys template like the one below to facilitate the brainstorming session.

Once you have asked ‘why’ five times and figured out the root cause, come up with improvement measure you need to apply. Assign everyone the corrective actions that need to be taken.

Cause and Effect Analysis

Once you have identified the problem, you can use the cause and effect analysis to explore the causes of a problem and its effects.

For the analysis, you can use a cause and effect diagram, which is also known as a fishbone diagram or the Ishikawa diagram.

Just as it helps explore the factors that are preventing an outcome, it can also be used to identify the factors needed to generate the desired outcome.

Here’s how to use the cause and effect analysis to solve business problems . You can also refer to our guide on fishbone diagrams to learn how to use the tool in more detail.

Pareto Chart

Pareto chart is a combination of a bar chart and a line graph. While the length of the bars represent the frequency or cost of faults, they are arranged in such a way that highlights the most frequent to least frequent. The chart helps prioritize your issues based on the cumulative effect they have on a system.

The Pareto chart is based on the theory that 80% of the total problems that occur are caused by 20% of problem causes. This means if you have solutions to your major problems, you can also solve a majority of your other smaller problems.

Learn how to create a Pareto chart step-by-step here .

Scatter Diagram

Scatter diagrams or scatter plot diagrams can be used to visualize the relationship between two variables. Once you have created a cause and effect diagram and identified potential causes to your problem, you can use the scatter diagram to determine which causes are responsible for the variation.

While the independent variable is plotted along the horizontal axis, the vertical axis is for the dependent axis. Learn more here .

Fault Tree Analysis

Fault tree analysis is a deductive analysis to that visually represent the failure path. You can use the fault tree analysis to determine the possible causes of a problem or an event. The fault tree starts with the event at the top and the possible causes are placed below.

Anymore Root Cause Analysis Tools?

What other root cause analysis tools do you use? Have you got any more tips on accelerating the root cause analysis steps we have discussed above? Do share them with us in the comments below.

Join over thousands of organizations that use Creately to brainstorm, plan, analyze, and execute their projects successfully.

More Related Articles

Leave a comment Cancel reply

Please enter an answer in digits: 2 × 2 =

Download our all-new eBook for tips on 50 powerful Business Diagrams for Strategic Planning.

- RCA 101 – 5-Why Analysis (Free Training)

- RCA201 – Basic Failure Analysis

- RCA 301 – PROACT® RCA Certification

- RCA401 – RCA Train The Trainer

- Other Trainings

- 5 Whys Root Cause Analysis Template

- RCA Template

- Chronic Failure Calculator

Root Cause Analysis with 5 Whys Technique (With Examples)

By Sebastian Traeger

Updated: April 23, 2024

Reading Time: 7 minutes

What Is the 5 Whys Technique?

Example of the 5 whys technique, how to conduct a 5 whys analysis in 5 steps, when to use a 5 whys analysis, using 5 whys template, tips for mastering the 5 whys technique, frequently asked questions about 5 whys.

With over two decades in business – spanning strategy consulting, tech startups and executive leadership – I am committed to helping your organization thrive.

At Reliability, we’re on a mission to help enhance strategic decision-making and operational excellence through the power of Root Cause Analysis, and I hope this article will be helpful!

Our goal is to help you better understand 5 whys techniques by offering insights and practical tips based on years of experience. Whether you’re new to doing RCAs or a seasoned pro, we trust this will be useful in your journey towards working hard and working smart.

The 5 Whys Technique is like peeling an onion – it helps you uncover the underlying reasons behind a problem, layer by layer. By repeatedly asking “why” at least five times, this method digs deep to reveal the root cause of an issue. It’s a simple yet powerful problem-solving approach that aims to get to the heart of the matter rather than just addressing surface-level symptoms.

5 Whys Technique: A method that involves iteratively asking “why” five times to unveil the fundamental cause of a problem.

In essence, the 5 Whys Technique is not just about fixing what’s broken on the surface; it’s about understanding and addressing the deeper issues that lead to problems in the first place.

The 5 Whys Technique is like a detective, uncovering the truth behind recurring problems. Let’s take a look at how this method works in two different scenarios.

Case Study: Manufacturing Defects

Imagine a company that keeps encountering the same manufacturing defects despite various attempts to fix them. By using the 5 Whys Technique, they discovered that the defects were not caused by faulty machinery, as previously assumed, but rather by human error due to unclear operating instructions. This realization led to improved training procedures and clear work guidelines, ultimately eliminating the defects.

Application in Service Industry

Now, consider a service industry struggling with frequent customer complaints and service failures. Through the 5 Whys Technique, it was revealed that these issues stemmed from inadequate staffing levels during peak hours. By addressing this root cause, such as hiring additional staff or adjusting schedules, the service quality can significantly improve, leading to higher customer satisfaction.

These examples illustrate how the 5 Whys Technique can be applied across different sectors to identify and address underlying issues effectively.

Step 1: Identify the Problem

Before diving into a 5 Whys analysis, it’s crucial to clearly identify the problem or issue at hand . This step sets the stage for the entire process and ensures that the focus remains on addressing the right concern. Take the time to gather relevant data, observe patterns, and consult with team members or stakeholders to gain a comprehensive understanding of the problem.

Step 2: Ask ‘Why’ Five Times

Once the problem is clearly defined, it’s time to start peeling back the layers. The process involves asking “why” five times, not necessarily limited to five questions but enough to delve deeper into the underlying causes of the problem . Each “why” serves as a gateway to uncovering additional factors contributing to the issue. This iterative approach helps in identifying not just one cause, but multiple interconnected elements that may be at play.