- Search Search Please fill out this field.

What Is Six Sigma?

Understanding six sigma, the 5 steps of six sigma.

- Lean Six Sigma

- Certification and Belt Rankings

The Bottom Line

- Corporate Finance

What Is Six Sigma? Concept, Steps, Examples, and Certification

Adam Hayes, Ph.D., CFA, is a financial writer with 15+ years Wall Street experience as a derivatives trader. Besides his extensive derivative trading expertise, Adam is an expert in economics and behavioral finance. Adam received his master's in economics from The New School for Social Research and his Ph.D. from the University of Wisconsin-Madison in sociology. He is a CFA charterholder as well as holding FINRA Series 7, 55 & 63 licenses. He currently researches and teaches economic sociology and the social studies of finance at the Hebrew University in Jerusalem.

:max_bytes(150000):strip_icc():format(webp)/adam_hayes-5bfc262a46e0fb005118b414.jpg)

Investopedia / Zoe Hansen

Six Sigma is a set of techniques and tools used to improve business processes. It was introduced in 1986 by engineer Bill Smith while working at Motorola. Six Sigma practitioners use statistics, financial analysis, and project management to identify and reduce defects and errors, minimize variation, and increase quality and efficiency.

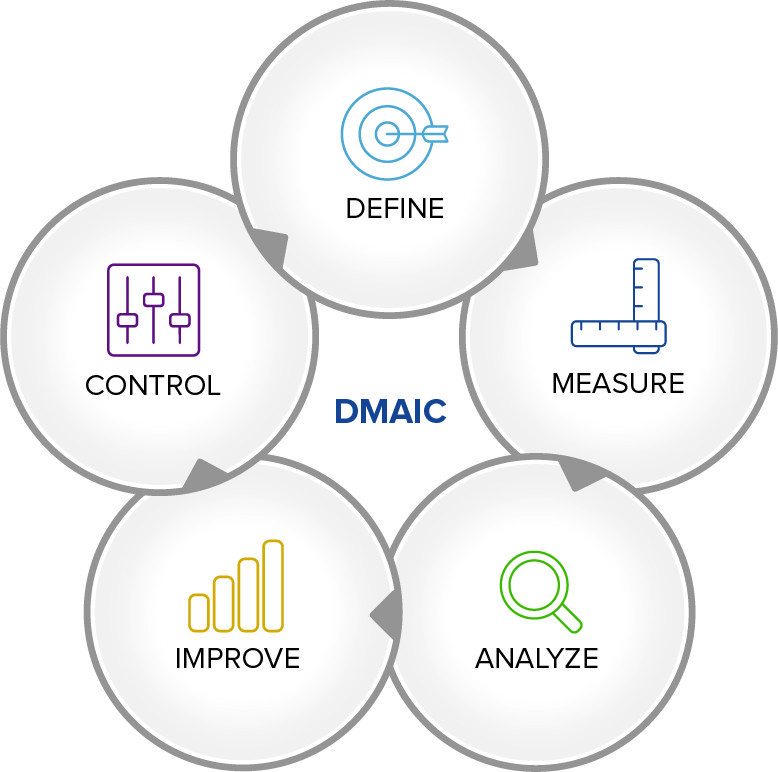

The five phases of the Six Sigma method, known as DMAIC, are defining, measuring, analyzing, improving, and controlling.

Key Takeaways

- Six Sigma is a quality-control methodology that businesses use to significantly reduce defects and improve processes.

- The model was developed by a scientist at Motorola in the 1980s.

- Companies often use the Six Sigma model to increase efficiency and boost profits.

- Six Sigma practitioners can earn certifications modeled on the color belts used in martial arts.

Six Sigma is based on the idea that all business processes can be measured and optimized.

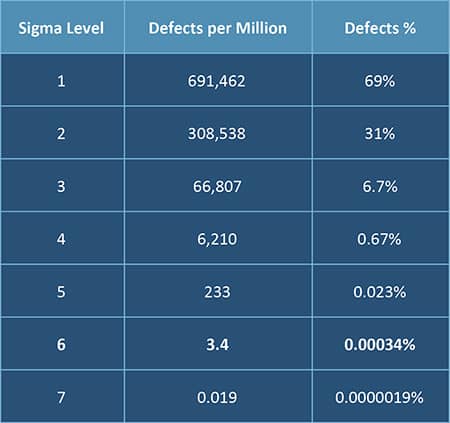

The term Six Sigma originated in manufacturing as a means of quality control. Six Sigma quality is achieved when long-term defect levels are below 3.4 defects per million opportunities (DPMO).

Six Sigma has since evolved into a more general business concept, focusing on meeting customer requirements, improving customer retention, and improving and sustaining business products and services. Among its best-known proponents was the longtime General Electric CEO Jack Welch .

Six Sigma certification programs confer belt rankings similar to those in the martial arts, ranging from white belt to black belt.

The Six Sigma method uses a step-by-step approach called DMAIC, an acronym that stands for Define, Measure, Analyze, Improve, and Control. According to Six Sigma adherents, a business may solve any seemingly unsolvable problem by following these five steps.

A team of people, led by a Six Sigma expert, chooses a process to focus on and defines the problem it wishes to solve.

The team measures the initial performance of the process, creating a benchmark, and pinpoints a list of inputs that may be hindering performance.

Next the team analyzes the process by isolating each input, or potential reason for any failures, and testing it as the possible root of the problem.

The team works from there to implement changes that will improve system performance.

The group adds controls to the process to ensure it does not regress and become ineffective once again.

What Is Lean Six Sigma?

Lean Six Sigma is a team-focused managerial approach that seeks to improve performance by eliminating waste and defects while boosting the standardization of work. It combines Six Sigma methods and tools and the lean manufacturing/ lean enterprise philosophy, striving to reduce the waste of physical resources, time, effort, and talent while assuring quality in production and organizational processes. Any use of resources that does not create value for the end customer is considered a waste and should be eliminated.

Six Sigma Certification and Belt Rankings

Individuals can obtain Six Sigma certification to attest to their understanding of the process and their skills in implementing it. These certifications are awarded through a belt system similar to karate training. The belt levels are:

- White belt : Individuals with a white belt have received some instruction in the basics of Six Sigma, but have not yet gone through any formal training or certification program. This gives them enough knowledge to become team members.

- Yellow belt : This level can be attained after several training sessions, and equips participants with the knowledge to lead small projects and assist managers who hold more advanced belts.

- Green belt : To achieve this level, individuals take a more comprehensive course that prepares them to become project leaders.

- Black belt : After reaching the green belt level, participants can move on to black belt certification, preparing them for leadership roles in larger and more complex projects.

People with black belts can become masters and champions. Someone with a master black belt is considered an expert and strong leader with excellent problem-solving skills. A champion is a lean Six Sigma leader trained in maximizing profits through the elimination of waste and defects.

These certifications, and the courses required to obtain them, are offered by a variety of companies and educational institutions and can differ from one to another.

Real-World Examples of Six Sigma

Six Sigma is used by many companies, local governments, and other institutions. Here are two examples of how Six Sigma improved operational efficiency, saved money, and increased customer satisfaction.

Microsoft (MSFT) is one of the largest software producers in the world. It used Six Sigma to help eradicate defects in its systems and data centers and systematically reduce IT infrastructure failures.

The company first established standards for all of its hardware and software to create a baseline measurement for detecting defects. It then used root-cause analysis, including collecting data from past high-priority incidents, server failures, and recommendations from product group members and customers, to pinpoint potential problem areas.

Large amounts of data were collected on a daily and weekly basis from various servers. The incidents were prioritized based on how severely the defects affected the business and the company's underlying services. Data analysis and reporting identified the specific defects, after which remediation steps for each defect were established.

As a result of Six Sigma, Microsoft says it improved the availability of its servers, boosted productivity, and increased customer satisfaction.

Ventura County, California, Government

Ventura County, California, credited the use of Lean Six Sigma for a savings of $33 million. The county government began to use the program in 2008 and has trained more than 5,000 employees in the methodology. The county says the savings are due in part to the introduction of more efficient new systems and the elimination of unnecessary, but time-consuming, steps from its prior processes.

For example, the VC Star newspaper reported in 2019 that the county saved "$51,000 with an appointments system that reduced labor costs and rates for maintenance of county vehicles [and] almost $400,000 annually by implementing a new system to track employee leaves of absence."

How Can You Get Six Sigma Certification?

You can receive Six Sigma certification through private companies, associations, and some colleges. Keep in mind, though, that there is no single governing body that standardizes the curriculum. This means that courses can vary based on where you take them.

Can You Get Six Sigma Certification Online?

Yes, many of the universities and organizations that offer Six Sigma certification have both classroom and online offerings.

What Is the Basic Difference Between Six Sigma and Lean Six Sigma?

Lean Six Sigma uses the Six Sigma methodology (define, measure, analyze, improve, control) with the specific goal of eliminating waste in a company's, or other organization's, processes or use or materials—that is, making it "leaner." It derives in part from the principles of lean manufacturing.

Six Sigma has become a widely used quality-improvement methodology in both the private and public sectors. Anyone who wishes to learn it can take courses that lead to various levels of certification.

ASQ. " What Is Six Sigma? "

Purdue University. ' Six Sigma Belt Level Rankings ."

Microsoft. " Microsoft Announces Accelerator for Six Sigma ."

VC Star . " Efficiency Program Rooted in Car Business Drives $33 Million in Government Savings ."

:max_bytes(150000):strip_icc():format(webp)/terms-l-lean-six-sigma-asp-FINAL-04b4432d5a954ad4a7baa78e42113aa5.jpg)

- Terms of Service

- Editorial Policy

- Privacy Policy

- Certified ScrumMaster

- PMI-ACP Exam Prep

- Leading SAFe® 6.0 Certification

- SAFe Scrum Master

- Certified Scrum Product Owner (CSPO)

- SAFe for Teams

- Agile Scrum Foundation

- AgilePM Foundation and Practitioner Certification

- Agile Scrum Master (ASM)

- Kanban Training

- Scrum Fundamentals

- PMP Certification

- Project Management Fundamentals

- CAPM Exam Prep

- Change Management Foundation and Practitioner Certification

- PRINCE2 Foundation & Practitioner Certification (7th Edition)

- PRINCE2 Agile Foundation & Practitioner Certification

- Business Analysis Foundation and Practitioner Certification

- Microsoft Project Training

- JIRA Certification Training

- Lean Project Management

- ITIL 4 Foundation

- VeriSM™ Foundation

- SIAM Foundation

- SIAM Professional

- 7 QC Tools Training

- Minitab Essentials

- Lean Six Sigma Yellow Belt

- Six Sigma Awareness

- Lean Six Sigma Green Belt

- Design for Six Sigma

- Lean Six Sigma Black Belt

- Lean Fundamentals

- Value Stream Mapping

- Quality by Design

- Quality Function Deployment

- BPM and Six Sigma

- RCA through Six Sigma

- DevOps Foundation

- DevOps Master

- DevOps Professional

- Continuous Delivery Architecture

- COBIT 5 Certification

- Corporate Group Training

- 1-to-1 Training

- Join as a Trainer

- Top Blogs on Quality Management

Real-Life Examples of Six Sigma Implementation – Six Sigma Examples/ Use Cases

Six Sigma is a creative and flexible series of methodologies aimed at improving organizational process quality and effectiveness. This blog on Six Sigma examples will explain a few use cases of Six Sigma methodology. Business today requires companies to be operational at maximum efficiency and effectiveness. The competitive markets mean everyone is looking to distinguish themselves and offer better products and services. A sustainable way to introduce better business practices is by changing your approach fundamentally.

Companies are built to achieve corporate goals. The methods to achieve them are plenty and streamlined by management for incorporation. The concepts of optimization, minimizing waste, and maximizing productivity are strongly incorporated into the foundation of Lean and Six Sigma principles.

These business models are conceptual and can be adapted to any industry or business environment. All you need is a guided professional and a willingness to convert your better business practices into the best possible. In this article, let us explore some Six Sigma examples and success stories.

What is Six Sigma?

The definition of Six Sigma has been under much debate. It can be broadly classified into four concepts:

A Philosophy – Six Sigma is a school of thought that views workflows and activities as processes that can be expounded, quantified, analyzed, bettered, and monitored. It states an input is required to produce an output. Therefore, exercising control over the input gives you a firm hand in managing output. It is sometimes expressed in the equation y=f(x) where x stands for the input and y for the output.

A Set of Tools – Six Sigma comprises controls such as qualitative techniques and quantitative tools used to improve business capabilities internally. Six Sigma tools include SPC (statistical process control), FMEA (failure mode and effects analysis), and control charts. Professionals who deal with Six Sigma explain that tools are continually evolving and are not set in stone.

A Methodology – Six Sigma is considered to be a derivative of the DMAIC approach . DMAIC is a data-centric improvement method that operates cyclically. It revolves around Defining, Measuring, Analyzing, Improving, and Controlling. This principle drives Six Sigma users to begin by understanding the existing problem and implementing long term solutions.

A Metric – When assessing Six Sigma as a metric, it is defined as 3.4 defects per million opportunities.

Six Sigma, in its simplest form, reduces the possibility of variation in production. The objective is to have a firm grasp on the production process. Lean Six Sigma is a term often associated with Six Sigma. Lean methods are used to minimize wastage during production; this includes time and resources spent on processes that do not directly contribute to better output from activities. Lean Six Sigma is a philosophy that brings together waste minimization and production optimization. It improves customer satisfaction by removing unnecessary processes and waste, creating better workflows, faster output, and possibly a competitive advantage. To attest to the importance of Six Sigma, in the next section of this article, let us explore some Six Sigma examples.

Implementing Six Sigma

Six Sigma can be implemented in a number of strategies, however there are two baseline options provided to all organizations looking to make the transition;

Introducing Six Sigma Training

Organizations can introduce a fundamental revamp across the organization through a Six Sigma program. Expose employees to better practices and conditioning by introducing the fundamentals and allowing a professional to understand what Six Sigma is and what it helps with. It is important to note that it is mostly an information transfer that happens during Six Sigma training . It is up to the business to adopt the methods to the organization and its practices.

Introducing Six Sigma Infrastructure

Creating a Six Sigma infrastructure can be quickly moved along by introducing certified professionals into your organization. Often called “Black Belts”, they move into your business for a period of four weeks to four months and begin teaching your business how to adapt the strategies to your activities. Creating the infrastructure creates a firm guideline to make changes to operations and corporate culture.

Now let us look into some interesting Six Sigma examples and success stories.

Six Sigma Examples

There are several organizations across various industries that have adopted Six Sigma practices to great success . High profile clients include;

General Electric

The American multinational was struggling to improve overall product quality and service even with the best professionals onboarded. After running a six sigma method trial, the company was able to introduce better-streamlining measures into product assurance. As a result, revenue increased.

This Indian based technology behemoth was the industry frontrunner for consumer goods. However, their customer service was less than satisfactory. Enter Six Sigma. Over time the methods were used to neutralize threats and create a better experience for clients.

We all know and love the technology giant that gave us Windows and Office. A contributing factor to the success behind their service and products is Six Sigma. The industry leader has made it no secret that Six Sigma methods have enabled better back-end processes and, as a result, better user experience. It acts as a case in point for companies looking to transition into Six Sigma practices.

The telecommunications company was one of the first to implement six sigma methods. As a trial, the company implemented Six Sigma to assess the impact on improving product quality and streamlining the transition between services to revenue. The positive results created better company-wide performance and permanent incorporation.

Boeing Airlines

One of the world’s largest aerospace companies was having issues with air fans within the engines. Unable to pinpoint the exact problem, a group of experts were called in to investigate. They deduced the problem stemmed from FOD (foreign object damage). Upon more in-depth inspection using Six Sigma methods , they could trace the problem to a more fundamental manufacturing issue causing electrical issues along with the FOD.

Practically, the application for six sigma methods can be seen across any organization attempting to create better output. Introducing better control measures for various parts of the production process helps produce desirable results.

Final Thoughts

The beauty of Six Sigma methods lies in their ability to adapt to different environments. The increased efficiency and effectiveness are tangible in the success stories of industry giants implementing Six Sigma to success. Add to the real-life Six Sigma examples of by introducing skilled professionals or the Six Sigma infrastructure to your organization.

The enterprises usually divide their workforce depending on the hierarchy to get their employees trained in different Lean Six Sigma training programs in Yellow Belt, Green Belt, Black Belt, Master Black Belt, and Six Sigma Champion. To get a better understanding of which Lean Six Sigma course benefits the most for you or the team, check out some of the popular courses below to get a comprehensive understanding of the same:

Lean Six Sigma Yellow Belt Certification Training

Lean Six Sigma Green Belt Certification Training

Lean Six Sigma Black Belt Certification Training

Lean Fundamentals Certification Training

Lean IT Certification Training

7QC Tools Certification Training

Value Stream Mapping Certification Training

RELATED ARTICLES MORE FROM AUTHOR

What is Cost of Poor Quality (COPQ)?

Top 6 Quality Management Trends to Follow in 2024

What is the Plan Do Check Act (PDCA) Cycle?

Leave a reply.

Save my name, email, and website in this browser for the next time I comment.

- 14,496 Likes

- 444 Followers

- 101k Subscribers

- 2,170 Followers

Related Articles

Business Analysis Tutorial: A Comprehensive Guide For Beginners

Top 10 IT Certifications in 2024 and Beyond

7 Key Benefits of Using MS Project in Project Management

Agile vs. Waterfall – Definition, Difference, Comparison, Pros, and Cons

Key ITIL Concepts That One Should Know

Popular posts.

The Project Management Life Cycle Explained

What are the Roles and Responsibilities of a Quality Control Inspector

7 Cs of Effective Communication with Example

Top 10 Factors for Project Success

Quality Analyst Job Roles, Responsibilities, and Skills Explained!

Suggested posts.

- 7 Cs of Effective Communication with Examples

- Project Management Lifecycle

- Project Success Factors

- Quality Control Inspector Job Description

- Risk Management Examples

- QA Manager Job Description

- Quality Management Team Roles and Responsibilities

- Risk Management Tools & Techniques

- Quality Analyst Job Description

- What is Business Value

- Who are Project Stakeholders

- Importance of Project Management

- What is Project Management

- Project Management Skills

- Project Manager Job Description

- Agile Project Manager Interview Questions

- Risk and Compliance Manager Job Description

- Risk Management Process

- Project Scope Management

- Healthcare Project Manager Job Description

- Six Sigma Project Examples

- Risk Analysis Methods

- ITIL Service Lifecycle

- Risk Manager Job Description

POPULAR CATEGORIES

- Best Project Management Blogs 265

- Top Agile Blog Posts 158

- Top Blogs on Quality Management 127

- Latest IT Service Management Blogs 108

- Trending Articles on DevOps 65

- Popular Blogs on IT Security and Governance 55

- Top Blogs on Professional Development 33

- Top Infographics Collection 8

Download E-book Blog

Thank You for submitting your enquiry. One of our training consultants will get in touch with you shortly.

50+ Training and Certification Programs - Upskill Today Learn more about our training programs.

A tool used to identify and reduce errors and increase the efficiency of business processes

What is Six Sigma?

Six Sigma is a term used to define various techniques and management tools designed to make business processes more efficient and effective. It provides statistical tools to eliminate defects, identify the cause of the error, and reduce the possibilities of error. Thus, Six Sigma creates an environment of continuous process improvement, enabling businesses to provide better products and services to customers. It was developed by Motorola, Inc. in 1986.

Six Sigma can be applied to any process in any industry to establish a management system for identifying errors and eliminating them. It provides methods to improve the efficiency of business structure and quality of processes, enhancing the profitability of the business.

The term “Six Sigma” is derived from the bell curve in statistics, in which sigma represents the standard deviation from the center. Hence, a process with six sigmas will achieve an extremely low defect rate. The failure of a business process or product is regarded as a defect. When a process produces less than 3.4 defects for one million chances, it is considered efficient.

- Six Sigma is used to identify and reduce errors and increase the efficiency of business processes.

- The primary objective of Six Sigma is customer satisfaction, and to achieve the objective, various methods are followed to improve the performance of a product or business process.

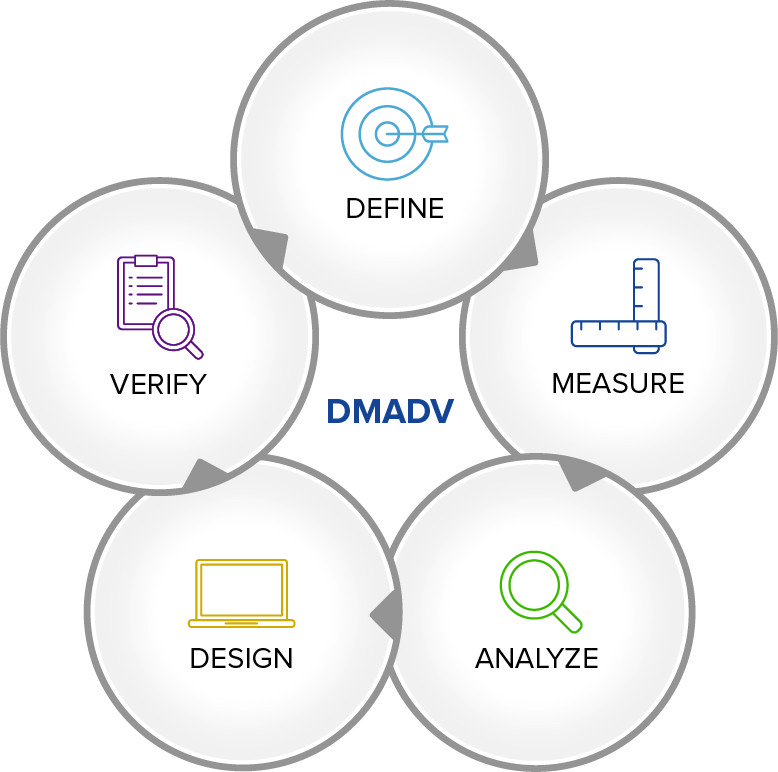

- DMAIC and DMADV are the main methodologies of Six Sigma that apply to different business environments.

Six Sigma Principles

There are five main principles of Six Sigma:

1. Customer focus

The main objective is to maximize the benefits for customers. Hence, a business must understand the needs of their customers and the drivers of sales. It requires establishing quality standards according to the market or customer demands.

2. Assess the value chain and find the problem

Outline the steps of a process to find out unwanted areas and gather related data. Define goals for data collection, purposes for data gathering, and expected insights. Verify that the data is assisting in achieving the objectives, whether more information is needed to be collected, or if data cleansing is required. Find out the problem and its root cause.

3. Eliminate defects and outliers

After the identification of the problem, make appropriate modifications in the process to eliminate defects. Eliminate any activity in the given process that does not contribute to the customer value. If the value chain is unable to reveal the problem area, various tools are used to find out the problem areas and outliers. Eliminating the outliers and defects removes the bottlenecks in a given process.

4. Involve stakeholders

A structured process should be adopted where all stakeholders collaborate and contribute to finding solutions to complex issues. The team needs to achieve proficiency in the methodologies and principles applied. Hence, specialized knowledge and training are required to lower project failure risks and ensure optimal performance of the processes.

5. Flexible and responsive system

Whenever an inefficient or faulty process is eliminated, the employee approach and work practices need to be changed. A flexible and responsive environment to the changes in processes can lead to the efficient implementation of the projects.

The departments involved should be capable of adapting easily to the change. Companies that periodically examine the data and make appropriate changes to their processes may achieve a competitive advantage.

Six Sigma Methodology

The following are the two main methodologies of Six Sigma, which are used in different business environments:

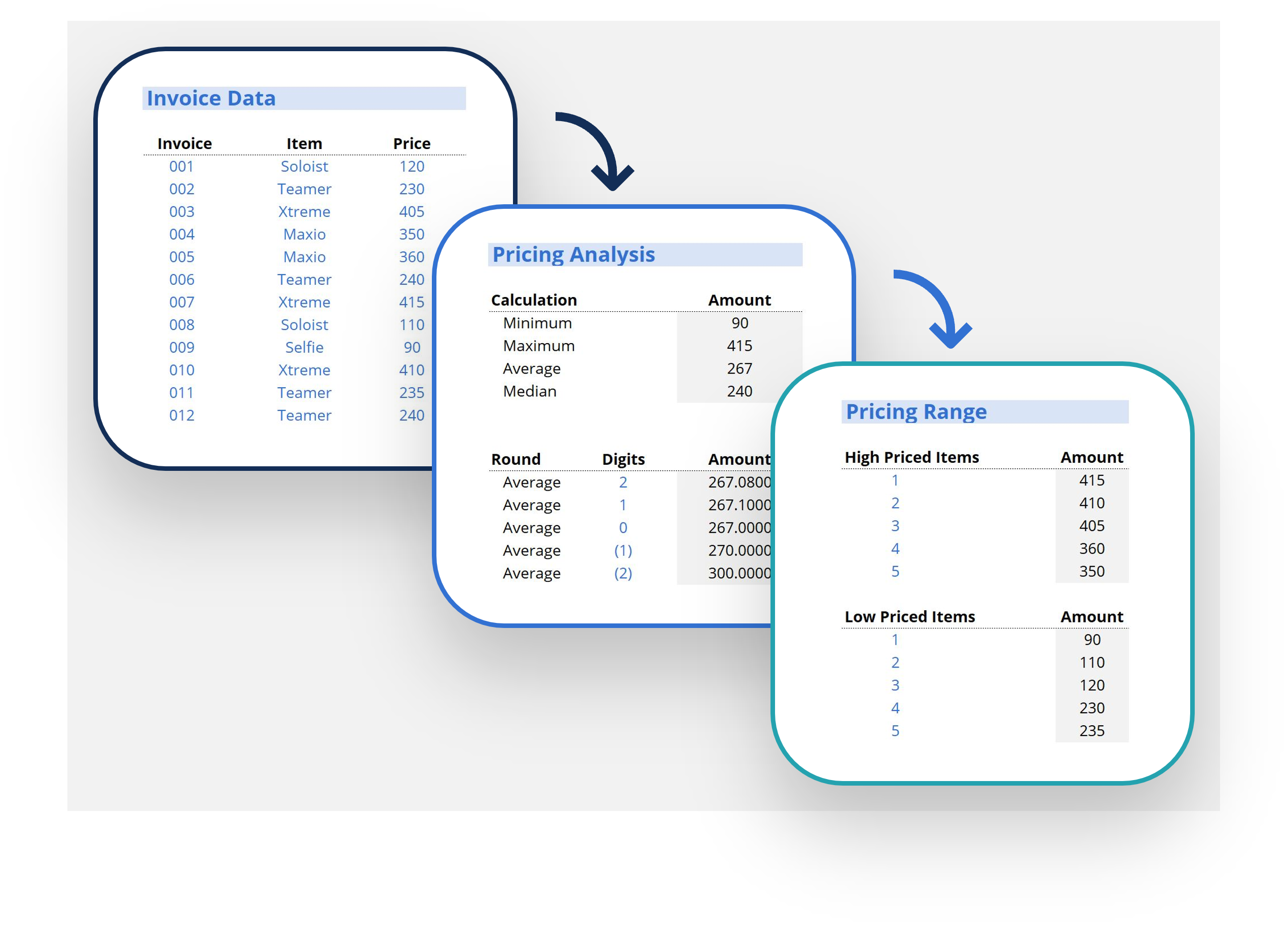

DMAIC is a data-driven approach used for optimizing and improving the existing business designs and processes. It is an effective method of controlled change management. The five phases of DMAIC are listed below, and each phase involves tools and tasks to help find the final solution.

- Define the problem and the goals of the project

- Measure the different aspects of the existing process in detail

- Analyze data to find the main flaw in a process

- Improve the given process

- Control the way the process is implemented in the future

DMADV focuses on the development of an entirely new process, product, or service. It is used when existing processes, even after improvement, do not satisfy the customer’s needs, and new methods are required to be developed. It comprises five phases:

- Define the purpose of the project, product, or service

- Measure the crucial components of a process and product capabilities

- Analyze data and develop design alternatives, ultimately selecting the best design

- Design the selected best alternative and test the prototype

- Verify the effectiveness of the design through several simulations and a pilot program

Related Readings

CFI is the official provider of the Commercial Banking & Credit Analyst (CBCA)™ certification program, designed to transform anyone into a world-class financial analyst.

To keep learning and developing your knowledge of financial analysis, we highly recommend the additional resources below:

- Competitive Advantage

- Decision Analysis (DA)

- Organization Design

- Strategic Management

- See all management & strategy resources

- Share this article

Create a free account to unlock this Template

Access and download collection of free Templates to help power your productivity and performance.

Already have an account? Log in

Supercharge your skills with Premium Templates

Take your learning and productivity to the next level with our Premium Templates.

Upgrading to a paid membership gives you access to our extensive collection of plug-and-play Templates designed to power your performance—as well as CFI's full course catalog and accredited Certification Programs.

Already have a Self-Study or Full-Immersion membership? Log in

Access Exclusive Templates

Gain unlimited access to more than 250 productivity Templates, CFI's full course catalog and accredited Certification Programs, hundreds of resources, expert reviews and support, the chance to work with real-world finance and research tools, and more.

Already have a Full-Immersion membership? Log in

Six Sigma for Beginners

By Kate Eby | May 29, 2017 (updated August 9, 2022)

- Share on Facebook

- Share on LinkedIn

Link copied

For at least a century, the industrial world has striven for ever greater efficiency in production and higher quality in output. The quest was defined by people like Shewhart and Taylor in the early 20th century, and hasn’t stopped as theories and methods for improvement are posited, reviewed, tested, and implemented. One of the most influential methods expounded in the last 35 years is Six Sigma. Originally formulated in manufacturing, the methodology is now practiced in fields such as healthcare and finance, in Fortune 500 companies all over the world.

In this article, we’ll explain Six Sigma, its origins in American manufacturing and development, what tools it uses, and how you can train to become certified to practice Six Sigma. Plus, experts explain the benefits that Six Sigma can offer you and your company.

What Is Six Sigma?

When practiced well, Six Sigma can be a powerful tool. As consultant Jennifer Williams says , “I have not found an industry that could not benefit from Six Sigma.”

Six Sigma is a set of methods and tools for business process improvement and quality management. Six Sigma aims to improve quality by finding defects, determining their cause, and improving processes to increase the repeatability and accuracy of process results. By improving efficiency and decreasing defects, the quality and timeliness of product delivery improves, and with it, ideally, employee enthusiasm and confidence--and the company’s bottom line.

With the aim of achieving near perfect ouput, Six Sigma employs statistical methods to detect problems and improve processes. Data-driven improvement projects are executed with specific steps in a defined sequence and with specific improvement goals in mind, called value targets. Teams with in-depth knowledge of the Six Sigma methodology are established to sponsor, manage, and complete the project.

“Six Sigma is a methodology and set of tools that help us measure what we do and then improve what we do. It really can work in any industry and in any type of business because everywhere we have a process, we can study it, measure it, and try to make it better,” says Kimberly McAdams, a Six Sigma Master Black Belt and Principal with FireFly Consulting .

This popular methodology, which gained a foothold in American business in the 1980s, is now a worldwide practice. Proponents of Six Sigma tout its advantages, including reduced waste, improved understanding of customer requirements, reduced production time, and a cost savings of up to 50 percent .

What Is Lean Six Sigma?

A variation on the Six Sigma framework marries Lean Management principles with Six Sigma methodologies. Lean Management seeks to reduce waste and thereby production cycle time, whereas Six Sigma focuses on reducing variation among deliverables. As some see it, Six Sigma focuses on finding and fixing defects after the fact, while Lean tries to prevent defects from occurring in the first place. At its best implementation, Lean is introduced first to increase efficiency, and then Six Sigma methods are applied for fine-tuning. Manufacturing, healthcare, finance, IT, and other fields use Lean Six Sigma.

Sermin Vanderbilt is Founder of Lean and Six Sigma World Conference and President of the American Quality Institute . According to her, “Six Sigma is getting it right every time or most of the time, 99.9 percent of the time. Almost every organization does need Six Sigma. Six Sigma is about accuracy. Lean is about cutting the costs, cutting time, so they go hand in hand.”

In short, what is Six Sigma? In the words of perhaps its most famous proponents, Jack Welch, “Six Sigma is a quality program that, when all is said and done, improves your customer’s experience, lowers your costs, and builds better leaders.”

Project Management Guide

Your one-stop shop for everything project management

Ready to get more out of your project management efforts? Visit our comprehensive project management guide for tips, best practices, and free resources to manage your work more effectively.

View the guide

History of Six Sigma

Although the term sigma (with a lowercase s) was used as far back as the 1920s in statistical process control, Motorola first named Six Sigma as a quality goal in 1984. The previous 60 years of quality improvement theory, including Total Quality Management and Zero Defects helped develop the formal methods known today.

Over time, Motorola realized that they could apply many of the tools and methods used to achieve fewer defects in parts manufacturing to other aspects of business. In the years that followed, other large companies such as Allied Signal also adopted the methodology. But Six Sigma attained true star status in the late 1990’s when GE’s chairman and CEO, Jack Welch, proclaimed phenomenal savings as a result of of Six Sigma.

ISO (International Organization for Standardization) published its first certification for Six Sigma in 2011, but no single governing Six Sigma organization publishes the definitive body of knowledge. Companies, institutions of higher learning, and consulting companies may offer standards and training that differ slightly.

The 2000s saw Lean Manufacturing , with an emphasis on reducing waste and improving process flow, combined with Six Sigma principles to form Lean Six Sigma. This framework offers organizations methodologies for streamlining processes and then detecting and removing defects and inefficiencies.

Six Sigma: What’s In a Name?

Six Sigma derives from statistical process modeling in manufacturing. A sigma is a measure of standard deviation, abbreviated as small s, or the Greek letter, σ. Something that is within +/-6s, Six Sigma, from the centerline of a control chart was created by a process that is considered well controlled. In other words, there is little deviation from the standard and is within tolerance. Six Sigma is sometimes written as 6σ. Motorola trademarked the name in the 1990s with capital letters.

Six Sigma Processes

In practical terms, a Six Sigma process produces 99.99966% of all deliverables, called opportunities, free of defects. Essentially, the process produces 3.4 defects per million opportunities (DPMO). You can also think of Sigma levels as how far a process or deliverable deviates from perfection. An important concept is to think of sigma defects as not meeting customer expectations. Aiming for Six Sigma level, you have a high probability of producing items that are well within specification. Several Sigma levels exist, each of which indicates the number of allowed defects per million and thus the level of maturity of a process, as is indicated in the table that follows.

Six Sigma level processes may not always be necessary to a business or they may not be good enough. McAdams explains, “In many cases, Six Sigma is really good quality and in other cases, it’s not. I came from the semiconductor industry and in most cases we needed much higher than a Six Sigma level performance.” On the other hand, business and finance environments may be fine with 2 Sigma processes. “It’s an improvement if you can move a process from a 2 Sigma to a 4 Sigma,” McAdams says. “It’s just always about reducing errors and reducing waste in what you do.”

Some theoreticians also consider that processes deteriorate over time in a 1.5 Sigma shift. Statistically, this means that the process will deviate 1.5 Sigma from the centerline of a control chart.

What Are the Benefits of Six Sigma?

As a new methodology, Six Sigma focussed on measurable goals, especially financial goals. You can achieve the goals through data-driven decisions, based on statistical processes, and not hypotheses.

“Control charts have been around for almost 100 years, but being able to take a methodology, really define a problem up front, find what a customer needs, and then start using these business and statistical tools to really dig in, that’s what helped Six Sigma become so powerful,” says McAdams.

“Data is fun,” asserts Jennifer Williams a Six Sigma Master Black Belt with an MBA and President and CEO of Integrity Business Consulting . “With data, you say, whoa, I didn’t know that this was happening, and it just paints a whole other picture. There’s nothing like giving data-driven decisions or recommendations.”

Indeed, many companies credit Six Sigma with earning them substantial savings. For example, Motorola touts a savings of $17 billion. Although the initial results of work with Six Sigma at GE were less promising, between 1995 and 2000, Six Sigma processes are said to have saved the company $12 billion. Over 50 percent of Fortune 500 companies use Six Sigma and credit the methodology with savings of over $400 billion in the past two decades.

Six Sigma is usually a practice that large corporations use, and some consider that the methodology requires significant adaptation for small organizations. In addition, formal certification may be prohibitively expensive for small companies, especially for more advanced certifications.

However, experts also see the advantages of Six Sigma for all organizations. “I would say that smaller companies need Lean and Six Sigma more than larger companies because they need to be so much more competitive to stay in business,” asserts Vanderbilt.

Although Six Sigma did originate in manufacturing, business and service industries have also realized its benefits as well. “What makes it a little more challenging sometimes, is that we can’t visualize the virtual, electronic processes, and so actually, in the end, the tools become even more important in that environment,” says McAdams. In manufacturing, you can go to the production floor and view the assembly line and time the processes. “A lot of our processes in the business world are happening over email and other electronic communications. But in some cases, it actually makes it easier to time, if we have good data coming from those systems.”

Williams adds that if you started out practicing Six Sigma in manufacturing, applying it to non-manufacturing, such as finance, requires some adjustments in thinking. Instead of putting a part down a conveyer belt, it’s handing off information from one department to another department or within the same department. “It’s following that value stream and seeing where the bottlenecks are, seeing the delays, and asking are we waiting? Is there overproduction? Are we over processing. We still can tie those quality improvement concepts to information or data.” Further, she adds, “I have not found an industry that could not benefit from Six Sigma.”

What Are the Six Sigma Principles?

Depending on where you look, you’ll find some slight variation on Six Sigma principles. In general, these are the thoughts that guide the approach.

- Continuous efforts to achieve stable and predictable process results are crucial to business success.

- Manufacturing and business processes have characteristics that can be defined, measured, analyzed, improved, and controlled (see DMAIC below).

- Achieving sustained quality improvement requires commitment from the entire organization, including and perhaps especially upper and middle management.

- All processes can be defined and analyzed in detail, and therefore improved: if you control the inputs, you can control the outputs.

- Continual evaluation is crucial. Stop what you’re doing and consider what went right or wrong.

- Eliminating variation saves money and reduces defect

The Six Sigma Methodologies

The principles of Six Sigma are executed through methodologies, or roadmaps to improvement, like a workflow. Two main methodologies are DMAIC and DMADV.

DMAIC , pronounced duh-may-ick , focuses on incrementally improving existing processes. It is the most widely known methodology and the one most associated with Six Sigma. Here’s a breakdown of the acronym:

D: Define customer needs, requirements, and project goals.

M: Measure the key aspects of the current process. According to McAdams, “This is when you start to understand your process and collect data on it.”

A: Analyze data. “You really dig into what types of errors occur and where they occur so you can target the big ones. It’s always looking at that 80/20 rule . Let’s see if we can find 20 percent of the reasons that give us 80 percent of the defects and let us reduce those,” says McAdams.

I: Improve processes. Test and verify that the improvements work.

C: Control future implementations of the processes to ensure that errors don’t creep in again.

Download DMAIC Roadmap Template

Excel | Word

DMADV , pronounced duh-mad-v , focuses on optimizing new products or processes to Six Sigma standards. Here’s a breakdown of the acronym:

D: Define customer or company goals.

M: Measure CTQs (characteristics that are Critical To Quality), measure product capabilities, production process capability, and risks.

A : Analyze data from your measurements.

D: Design the new process based on the analysis in the previous step.

V: Verify the design through a pilot run, implement the new process, and hand off to the process owner.

Download DMADV Roadmap Template

Excel | Word

An emerging methodology, particularly associated with Lean Six Sigma, is DFSS (Design for Six Sigma), with an emphasis on determining from the beginning what the customer wants and ensuring that defects and inefficiencies are anticipated and eliminated at the design phase of a process.

Analysis Tools

During the phases of these methodologies, Six Sigma practitioners use various existing tools to measure and analyze process and outcomes. A partial list of the most mentioned tools is as follows:

- Control charts

- Root Cause Analysis

- CTQ Tree (Critical to Quality)

- Statistical process control

- Process mapping

- ANOVA gauge R&R (analysis of variance gauge repeatability and reproducibility)

- Pareto charts

- Value Stream Mapping

- Business Process Mapping or Checksheet

- Cause and effects diagram or fishbone diagram or Ishikawa diagram

- Taguchi method

Who Makes It Happen? The Belts of Six Sigma

Execution of the Six Sigma methods relies on a team of trained practitioners sourced from throughout the company hierarchy. Management aligns the right projects with the right people and ensures that they can achieve goals and sustain success. The production team employs the methods to create a good result, and all participants must have Six Sigma training. Six Sigma borrows from the martial arts the concepts of belts to designate a level of methodological mastery.

- Executive Leadership: The CEO and other executive staff establish the vision for the Six Sigma implementation at the organization level, and support management.

- Champions: The executive leadership from upper management selects the Champions. They ensure that all departments in an organization work together to implement Six Sigma, and to mentor Black Belts.

- Master Black Belts: Champions select the Master Black Belts, who advise on Six Sigma practice for programs. Master Black Belts also train and mentor Black Belts and Green Belts, and identify potential Six Sigma projects for the company.

- Black Belts: Master Black Belts supervise Black Belts, who are responsible for executing the Six Sigma methodology for specific projects. Their sole focus is the statistical analysis and the correct execution of Six Sigma methodology.

- Green Belts: Guided by Black Belts, Green belts are employees who implement Six Sigma recommendations as part of their regular duties. They may also lead projects part of the time.

- Yellow Belts: Yellow Belts have a basic knowledge of Six Sigma, but they may be either new to the methodology or need only a basic understanding as, for example, a Champion or an Executive. Yellow Belts may participate in projects by finishing such tasks as creating process maps, and working on smaller improvement efforts within larger projects.

- White Belts: New to Six Sigma concepts, White Belt certification takes only a few hours, and typically does not include testing.

Training and Certifications for Six Sigma Belts

Many training organizations offer Six Sigma certification, although no one official body of training knowledge or certification exists. Different schools and individual companies may offer their own variations. Some training institutions and consultancies do band together to provide a version that they accept. The Council for Six Sigma Certification , for example, accredits Six Sigma trainers to guarantee their curriculum meets a basic standard. The International Association for Six Sigma Certification (IASSC) provides certifications for Lean Six Sigma.

Training can be in a classroom, onsite, self-paced, online, or a combination of all. Certificates are awarded upon successful completion of a written exam, which may be taken online or on paper.

Aside from being a workplace requirement, a Six Sigma certification presents well on a resume, and can garner as much in salary as an MBA. Learn more about Six Sigma certifications by reading What You Need to Know About Six Sigma Certifications and Belts .

Formal training may not be necessary. “You don’t need the Belts to implement it,” says Sermin. “You just need to have the philosophy and the belief that you need Lean and Six Sigma to be competitive.” Training can be as simple as reading a basic Six Sigma book and deciding to focus on efficiency and to trim waste.

Six Sigma Glossary

Here are some common terms beyond those already mentioned in this article that all Six Sigma practitioners use.

5 Whys - An information gathering technique for exploring cause and effect.

7 Wastes - A Japanese concept describing how a business might waste resources. It is described by the acronym TIMWOOD, which stands for Transportation, Inventory, Motion, Waiting, Overprocessing, Overproduction, and Defects.

Acceptance, and Acceptable Quality Level (ACL) - This term refers to the acceptance of the product as meeting quality standards, or acceptance, or agreement with, a proposed action.

Activity Report - A report that tracks tasks, responsibilities, schedules, and duration.

Affinity Diagram - A diagram that captures the result of brainstorming activities, often used during the Improve phase of Six Sigma.

Analysis - A review and study of the data captured during the Measure phase.

ANOVA, ANCOVA, MANOVA, MANCOVA - The advanced statistical methods for comparing data.

Balanced Scorecard - A tool for aligning strategic elements and communicating strategy to the company.

Black Noise/White Noise - Elements that are always unpredictable and elements that are unpredictable, but will be eliminated with further information, respectively.

Business Improvement Campaign - An endeavour to improve processes throughout a company, not just on the manufacturing floor.

Business Process Management - An endeavour to improve workflow and flexibility throughout a company.

Cause-Effect Diagram - An Ishikawa diagram or fishbone diagram.

Checksheet - Also referred to as a frequency distribution or frequency distribution analysis. A tool held over from Total Quality Management. A simple chart used for collecting data over time in many instances to learn where problems occur. This chart helps to show the larger pattern of behavior, rather than making assumptions about the circumstances in which problems occurred.

Critical To Quality (CTQ) - An essential element that contributes to the success or quality in a process.

Defect - A failure to meet customer specifications or expectations, a failure within a process, or a physical defect.

Design For Six Sigma (DFSS) - Along with DMADV, DFSS focuses on listening to the customer to get the processes right before defects occur.

Define, Measure, Analyse Improve, Control, Improve (DMAIC) - The Six Sigma methodology for finding and fixing defects in a process.

Define, Measure, Analyze, Design, Verify (DMADV) - Similar to DFSS.

DPMO - An acronym that stands for Defects Per Million Opportunities.

Just-In-Time (JIT) - Just-In-Time is a production method that aims to minimize stock levels by producing products just in time for customer purchase.

Kaizen - A Japanese philosophy focusing on continuous improvement of process and people. The concept also influences Lean Thinking.

Materials Requirements Planning (MRP) - A methodology for optimizing material levels with production and delivery schedules.

Pareto - An analysis that looks for the 20 percent of activities that generate 80 percent of the benefits, or the 20 percent of problems that cause 80 percent of waste.

Plan, Do, Check, Act (PDCA) - The Total Quality Management method, and the precursor to DMAIC. Acknowledged as a foundational method in ISO 9000.

Process - Describes a workflow, or describes how Six Sigma is implemented.

Process Mapping - Including flow charting and value stream mapping, this is the process of creating a graphical representation of how things work

QxA=E - Quality multiplied by acceptance equals effectiveness. This equation originated in the Six Sigma program at GE.

Soft Skills - People skills, rather than statistical or process skills. The ability to influence people, build teams, communicate, empathize, and so forth.

Stakeholder - Internal and external customers, team members implementing a Six Sigma process and solution.

Tollgates - The review periods between Six Sigma stages.

Total Quality Management (TQM) - One of the original management systems, TQM teaches that every employee, management to janitor, is responsible for quality deliverables and a quality work experience.

X's/Big X's - The possible causes of the problem or the big Y.

Y's/Big Y's - The little aspects of a solution that serve the big Y, or main customer requirement.

Value Target - The financial goal for a Six Sigma project

Criticisms of Six Sigma

Nothing is perfect and Six Sigma has come under various criticisms. Some criticize what they see as the Black Belt industry, wherein it’s all too easy for anyone to hang up a shingle and start selling training and certifications. Others, such as the quality guru Joseph Juran felt that Six Sigma was, in effect, old wine in new bottles, that the principles were old and had simply been repackaged with fancy belts for certifications.

McAdams says that nothing is a panacea and success derives from a good implementation. “Just like any business methodology it’s sometimes practiced well and sometimes not so well. What it doesn’t really do, is fix the business strategy. A good strategy still needs to be in place. But the data that you can get from a good Six Sigma program and good projects can help you focus a business strategy. But, no, it’s not the end-all solution to saving a business.”

How Six Sigma Practitioners Use Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.

Discover why over 90% of Fortune 100 companies trust Smartsheet to get work done.

IMAGES

COMMENTS

Six Sigma is a quality-control methodology that businesses use to significantly reduce defects and improve processes. The model was developed by a scientist at Motorola in the 1980s.

Six Sigma, or 6ς, is both a methodology for process improvement and a statistical concept that seeks to define the variation inherent in any process. The overarching premise of Six

Author: Michael Scheiner. Cutting to the chase: just what is Six Sigma methodology? Six Sigma is a project and work methodology that’s all about reducing variables in your processes and deliverables. Unlike other lean methodologies, the main focus with Six Sigma is less about cutting costs and more about streamlining work.

Six Sigma is a creative and flexible series of methodologies aimed at improving organizational process quality and effectiveness. This blog on Six Sigma examples will explain a few use cases of Six Sigma methodology.

Six Sigma Methodology. The following are the two main methodologies of Six Sigma, which are used in different business environments: DMAIC. DMAIC is a data-driven approach used for optimizing and improving the existing business designs and processes. It is an effective method of controlled change management.

Managing Work. Agile project management. Six Sigma for Beginners. Try Smartsheet for Free. By Kate Eby | May 29, 2017 (updated August 9, 2022) For at least a century, the industrial world has striven for ever greater efficiency in production and higher quality in output.